film pet per trasferimento termico

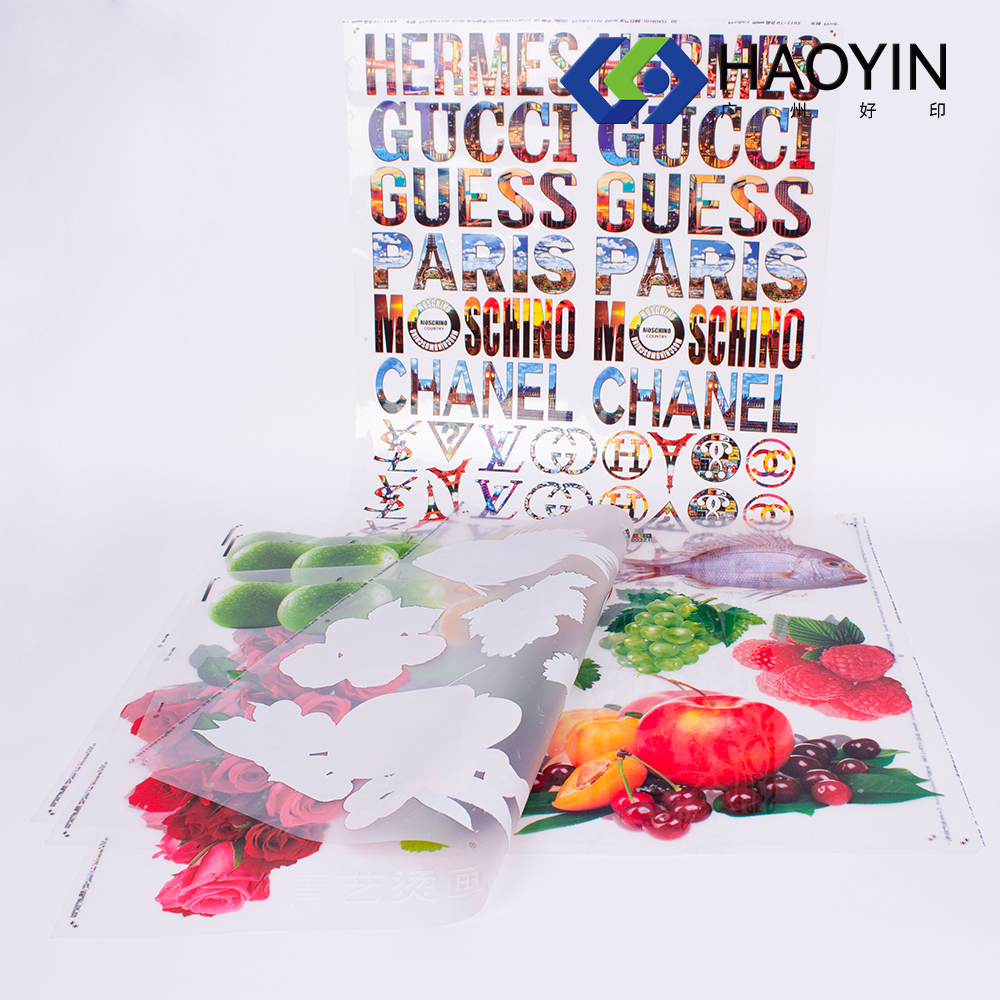

Il film PET per trasferimento termico è un materiale versatile e tecnologicamente avanzato, progettato per applicazioni di trasferimento d'immagine di alta qualità. Questo film speciale in polietilene tereftalato funge da mezzo cruciale nell'industria della stampa transfer, permettendo il trasferimento senza soluzione di continuità di design, grafiche e motivi su varie superfici. La particolare composizione del film presenta un rivestimento di rilascio che facilita la separazione dopo l'applicazione del calore, garantendo trasferimenti puliti e precisi. La sua struttura molecolare è stata studiata per resistere a temperature elevate mantenendo una stabilità dimensionale, risultando ideale sia per applicazioni industriali che commerciali. La superficie del film è trattata per accettare diversi tipi di inchiostri, tra cui solvente, eco-solvente e UV-curing, assicurando un'eccellente resa cromatica e chiarezza dell'immagine. Nelle applicazioni pratiche, il film PET per trasferimento termico viene ampiamente utilizzato nella stampa tessile, nella produzione di articoli promozionali, nell'abbigliamento sportivo e nella realizzazione di capi personalizzati. Lo spessore del film varia generalmente tra 15 e 100 micron, offrendo diverse opzioni in base alle esigenze applicative. La sua stabilità termica garantisce prestazioni costanti in differenti processi di stampa, mentre le sue ottime proprietà di planarità prevengono l'arricciamento e assicurano un regolare funzionamento sia nei sistemi manuali che automatizzati.