ရေပြင်မှုသည် DTF ဖিလံ၏ အလုပ်ဆောင်မှုကိုဘယ်လိုသက်ရောက်သနည်း

ထုတ်ဝေမှုဒေသများရဲ့ ရေပြင်မှုခြောက်စွမ်းကို သိပ္ပံပညာအရ လေ့လာခြင်း

DTF ပရင်တာများအလုပ်လုပ်ပုံအား ထိရောက်မှုရှိစေရန်အတွက် စိုထိုင်းဆကိုစုပ်ယူမှုသည် အရေးကြီးပါသည်။ ဖလင်သည် လေထုထဲမှ ရေစိုကိုစုပ်ယူသောအခါတွင် ပစ္စည်း၏ အခြေအနေနှင့် ဓာတုပြောင်းလဲမှုများကို ပြောင်းလဲစေပြီး နောက်ဆုံးထုတ်လုပ်သည့် ပရင်တာအရည်အသွေးကို ထိခိုက်စေနိုင်ပါသည်။ သုတေသနပြုလုပ်မှုများအရ ပစ္စည်းများသည် စိုထိုင်းဆကို မတူညီသောနှုန်းဖြင့် စုပ်ယူကြကြောင်းတွေ့ရှိခဲ့ပါသည်။ ပလပ်စတစ်အမျိုးအစားများစွာသည် စိုထိုင်းသောအခြေအနေတွင် မိမိ၏အလေးချိန်၏ ၁၀ ရာခိုင်နှုန်းခန့်ကို စုပ်ယူကြပါသည်။ ဤအချက်သည် ပရင်တာထုတ်လုပ်မှုအရည်အသွေးကို သက်ရောက်မှုရှိစေပါသည်။ စိုထိုင်းဆကိုဆွဲယူသော အပြုအမူကို hygroscopic ဟုခေါ်ပြီး DTF ဖလင်များတွင် တွေ့ရှိရသည့် အပြုအမူဖြစ်ပါသည်။ ဤဂုဏ်သတ္တိကို နားလည်ခြင်းသည် ပရင်တာများအတွက် ပစ္စည်းများနှင့်ကိုက်ညီသော စွမ်းဆောင်ရည်များကို ရွေးချယ်ရာတွင် ကူညီပေးပြီး ပရင်တာလုပ်ငန်းစဉ်များကို ပိုမိုချောမွေ့စေပြီး နောက်ပိုင်းတွင် မျှော်လင့်မထားသော ပြဿနာများကို ကြုံတွေ့ရခြင်းမှ ကာကွယ်ပေးပါသည်။

DTF လွှာများတွင် ရေပြင်မှုနှင့်ပတ်သက်သော အများအပြား အခြေအနေများ

စိုထိုင်းဆသည် DTF ပြောင်းလဲမှုများအတွက် အမှန်တကယ် စိတ်ရှုပ်စရာဖြစ်ပြီး ထိုကဲ့သို့ဖြစ်ပါက ပုံနှိပ်ထားသော ပုံများသည် ထက်မြက်မှုကိုဆုံးရှုံးလျက် အသေးစိတ်အချက်များ မကောင်းတော့ပေ။ အဆိုပါပြဿနာများသာမက စိုထိုင်းဆများပါးသောအခါတွင် အရောင်များ ပျောက်ကွယ်ခြင်းနှင့် အပိုင်းအခြားများ ဖြစ်ပေါ်လာခြင်းတို့သည် အများအားဖြင့် ဖြစ်ပေါ်လေ့ရှိပြီး အရောင်များ မျက်နှာပြင်များတွင် ကပ်ပါးခြင်းကို မကောင်းစေပေ။ ကျွန်ုပ်တို့၏ တွေ့ရှိချက်များအရ စိုထိုင်းသော အခြေအနေများတွင် ငြင်းပယ်ထားသော ပုံနှိပ်မှုများ၏ ၃၀% သည် အဆိုပါပြဿနာများကြောင့် ဖြစ်ပေါ်နေခြင်းဖြစ်သည်။ ထို့ကြောင့် ထုတ်လုပ်မှုလုပ်ငန်းစဉ်တွင် စိုထိုင်းဆကို ထိန်းချုပ်ခြင်းသည် အရေးကြီးပါသည်။

Ink Curing နှင့် Adhesion Processes တွင် ရေပြင်ခြင်း၏ သက်ရောက်မှု

DTF ပရင်တာလုပ်ငန်းစဉ်အတွင်း စိုထိုင်းဆအများအနည်းသည် မှိုင်းကောင်းစွာခံခဲ့ပြီး ပစ္စည်းများပေါ်တွင် ကပ်လျက်ရှိမှုကို တိုက်ရိုက်သက်ရောက်ပါသည်။ စိုထိုင်းဆများပြားလွန်းပါက မှိုင်းခံခြင်းလုပ်ငန်းစဉ်သည် ပျက်ပြားသွားပြီး မကောင်းသောကပ်လျက်ရှိမှုနှင့် မူလထက် သက်တမ်းနှိမ့်ခြင်းတို့ကို ဖြစ်ပေါ်စေပါသည်။ အချို့သောလေ့လာမှုများအရ ပရင်တာများသည် စိုထိုင်းဆတိုင်းတာကိရိယာမှ ပြသသော တန်ဖိုးများအရ မှိုင်းခံခြင်းအပူချိန်များကို ပြင်ဆင်ရန် လိုအပ်ကြောင်းတွေ့ရှိခဲ့ပြီး အလုပ်များကို ပြီးစီးရန် အချိန်ကို သက်ရောက်မှုရှိပါသည်။ စိုထိုင်းဆများသော ဧရိယာများတွင် လုပ်ငန်းလုပ်ကိုင်နေသည့် ဆိုင်များအတွက် မှိုင်းများကောင်းစွာကပ်လျက်ရှိရန် အပူချိန်နှင့် စိုထိုင်းဆအဆင့်များကို စောင့်ကြည့်ခြင်းသည် အလွန်အရေးကြီးပါသည်။ ရာသီဥတုထိန်းချုပ်မှုကို မှန်ကန်စေရန် လုပ်ဆောင်ခြင်းသည် ကောင်းမွန်သော ပရင်တာများနှင့် အားနည်းသော ပရင်တာများကို ဆေးထည့်ပြီး ဆေးထည့်ပြီးနောက် ပျက်ပြားသွားသော ပရင်တာများကြား ကွာခြားမှုကို ဖြစ်ပေါ်စေသော အချက်တစ်ခုဖြစ်ပါသည်။

ရေပြင်မှုကို ကန့်သတ်သော DTF ရောင်းပိုဒ်၏ အမြဲတမ်းသော အသုံးအဆင်များ

Hydrophobic Barriers ဖြင့် Ink Bleeding ကို ကန့်သတ်ခြင်း

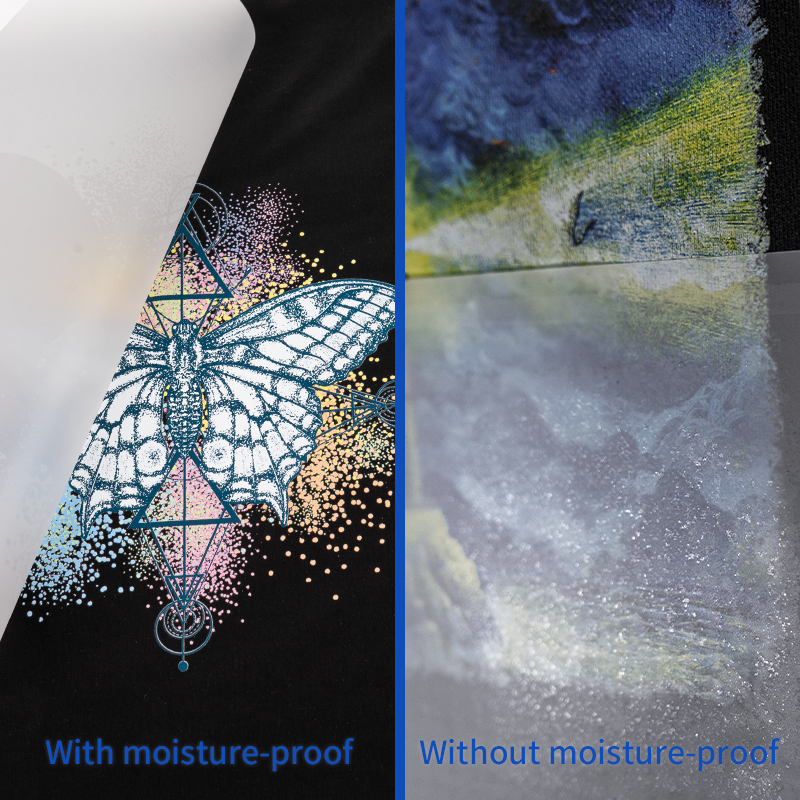

စိုထိုင်းမှုကိုခုခံနိုင်သော DTF ဖလင်များသည် ရေကိုနှင်ထုတ်သည့်အထူးကော့တင်များပါဝင်မှုကြောင့် ထုံးစံအတိုင်းထက် စွမ်းဆောင်ရည်ပိုမိုကောင်းမွန်ပါသည်။ ထိုကော့တင်များသည် ထုံးစံဖလင်များက စိုထိုင်းမှုကိုခံနိုင်ရည်မရှိသောအခါ စားလျက်ရှိသည့်အခြေအနေကို ကာကွယ်ပေးပါသည်။ အခြားသူများက စိုထိုင်းမှုကိုခံနိုင်ရည်ရှိသော ဖလင်များသည် ပုံမှန်ဖလင်များနှင့် နှိုင်းယှဉ်ပါက စားလျက်ရှိမှုပြဿနာကို တစ်ဝက်ခန့်လျော့နည်းစေသည်ဟု တွေ့ရှိခဲ့ပါသည်။ ထိုကဲ့သို့သော တိုးတက်မှုမှာ ပိုမိုစိုစွတ်သော ဧရိယာများတွင် အလုပ်လုပ်နေသောသူများအတွက် အထူးအရေးပါပါသည်။ ဥပမာ- ကမ်းရိုးတန်းဒေသများ သို့မဟုတ် မုန်တိုင်းဒေသများတွင်ရှိသော ပုံနှိပ်ဆိုင်များတွင် စိုစွတ်မှုသည် နေရာတိုင်းတွင် တည်ရှိနေသည့်အတွက် အထူးသက်ဆိုင်ရာရှိပါသည်။

အိပ်ချိန်လုပ်ငန်းများအတွင်း ဖိတ်၏ ပျင်းမှန်မှုကို ထိန်းသိမ်းခြင်း

စိုထိုင်းစေသော DTF ဖလင်များသည် အပူဖိအားချိန်ကာလများအတွင်း တည်ငြိမ်နေသောကြောင့် အမှန်တကယ် ထင်ရှားပါသည်။ ဤပစ္စည်းများဖြင့် အလုပ်လုပ်သည့်အခါတွင် တည်ငြိမ်မှုကို ထိန်းသိမ်းခြင်းသည် ကောင်းမွန်သော ပြောင်းရွှေ့မှုနှင့် အထူးကောင်းမွန်သော ပြောင်းရွှေ့မှုများကြားရှိ ကွာခြားမှုကို ဖြစ်စေပါသည်။ ၎င်းတို့ကို ထူးခြားစေသည့်အရာမှာ အဆိုပါပစ္စည်းမျက်နှာပြင်များ ကွေးခြင်းမှ တကယ်တမ်းတားဆီးသော တည်ဆောက်ပုံပင်ဖြစ်ပါသည်။ အထူးသဖြင့် စိုထိုင်းဆသည် ထိန်းချုပ်မရသောအခါတွင် အများအပြားဖြစ်ပျက်တတ်ပါသည်။ ဤတည်ငြိမ်မှုကြောင့် ပစ္စည်းသည် ထိတွေ့နေသော မည်သည့်မျက်နှာပြင်ပေါ်တွင်မဆို တစ်ပြေးညီ အသုံးချနိုင်ပါသည်။ သန့်ရှင်းသော ပြောင်းရွှေ့မှုများကို ရရှိခြင်းနှင့် ထုတ်လုပ်မှုအတွင်း အသုံးမကျသော ပစ္စည်းများကို လျော့နည်းစေရန်အတွက် အလွန်အရေးကြီးပါသည်။ ပိုနည်းသော ကွေးခြင်းသည် ပြဿနာများကို မကြာခဏ ရပ်တန့်၍ ပြုပြင်ရန်မလိုဘဲ အလုပ်များကို ပိုမိုမြန်ဆန်စွာ ပြီးမြောက်နိုင်သည်။

ပျိုးရောင်အတိုင်းအတာများ ပြောင်းလဲသော သြဂုတ်အချိန်အခြေအလျောက်များအတွင်း

စိုထိုင်းမှုကိုခံနိုင်ရည်ရှိသော DTF ဖလင့်များသည် မည်သည့်ရာသီတွင်မဆို ၎င်းတို့၏အရောင်များကို ကောင်းစွာထိန်းသိမ်းထားနိုင်သည်။ ထို့ကြောင့် တစ်နေရာလုံးတွင် အသုံးပြုရန် အကောင်းဆုံးဖြစ်သည်။ အချို့သော သုတေသနများအရ ဤဖလင့်များသည် ပုံမှန်ဖလင့်များနှင့် နှိုင်းယှဉ်ပါက အခက်အခဲများကိုကျော်လွှားရာတွင် အရောင်များကို မှန်ကန်စွာထိန်းသိမ်းထားနိုင်မှုသည် ၄၀% ပိုကောင်းမွန်ကြောင်း ပြသသည်။ ကုန်ပစ္စည်းများ၏ ပုံသဏ္ဍာန်အပေါ်တွင် ဂရုစိုက်သော ကုမ္ပဏီများအတွက် ဤအချက်သည် အရေးကြီးပါသည်။ အကြောင်းမှာ ကုန်အမှတ်တံဆိပ်ကို မှတ်မိနိုင်ရန် အရောင်များသည် တိကျမှန်မှန်ကန်ကန် ထိန်းသိမ်းထားရန် လိုအပ်သောကြောင့်ဖြစ်သည်။ အရောင်များ ပြောင်းလဲမသွားပါက ကုန်အမှတ်တံဆိပ်များသည် အမြဲတမ်း တောက်ပပြီး မှန်ကန်သော အရောင်များကို မျှော်လင့်နိုင်မည်ဖြစ်သည်။ ဤအချက်သည် ဆိုင်များတွင်ဖြစ်စေ၊ အွန်လိုင်းတွင်ဖြစ်စေ ကုန်ပစ္စည်းများကို ပိုမိုကောင်းမွန်စွာ ရောင်းချနိုင်ရန် ကူညီပေးသည်။ အများစုက သဘောတူမည့်အရာတစ်ခုဖြစ်သည်။

လုပ်ငန်းစဉ်မြင်မြင်သာသာမှုတွင် ပြင်ဆင်မှုများ

ရေအကျိုးကြောင့်ဖြစ်ပေါ်သော ရှုံးကိုင်များကို လျော့ချရန်

စိုထိုင်းဆကာကွယ်ပေးသော DTF ဖလင်များသည် ပုံနှိပ်ထုတ်လုပ်မှုတွင် စွန့်ပစ်ရသည့် ပစ္စည်းများကို အများအပြားလျော့နည်းစေပါသည်။ ထုတ်လုပ်သူများက ထိုကဲ့သို့ ဖလင်များသုံးပြီးနောက် စွန့်ပစ်ရသည့်နှုန်းမှာ ၃၅% ခန့် လျော့နည်းသွားကြောင်း ဖော်ပြကြပါသည်။ ကုမ္ပဏီများအတွက် ငွေကြေးချွေတာမှုကို တိုင်းတာနိုင်သည့် ကိန်းဂဏန်းများကို တစ်နေ့လျော့နည်းသွားသည့် စွန့်ပစ်ပိုမိုလျော့နည်းခြင်းသည် အမြတ်အစွန်းများလာစေပြီး ကုန်ကျစရိတ်ကိုလည်း လျော့နည်းစေပါသည်။ ကုမ္ပဏီများက အမြတ်အစွန်းကို စိတ်ပိုနှံ့စေသောအခါတွင် စွန့်ပစ်ပိုမိုလျော့နည်းခြင်းသည် သဘာဝပတ်ဝန်းကျင်အတွက်သာမက ငွေကြေးအရပ်ရပ်တွင်လည်း အကျိုးရှိကြောင်း အမြန်တကြ သိရှိလာကြပါသည်။ ယနေ့ခေတ်တွင် ဈေးကွက်များတွင် တစ်ပြားတစ်ချပ်အတွက်ပင် ယှဉ်ပြိုင်နေရသည့် အခြေအနေများတွင် ဉာဏ်ရည်စွမ်းရည်ရှိသော ကုမ္ပဏီများက စွန့်ပစ်ပိုမိုလျော့နည်းခြင်းသည် အသေးစိတ်အချက်များကို ဂရုမစိုက်သော ယှဉ်ပြိုင်ကုမ္ပဏီများထက် အကျိုးရှိစေသည့် အားသာချက်တစ်ခုဖြစ်ကြောင်း သိရှိကြပါသည်။

Ropical ပတ်ဝန်းကျင်များတွင် ထုတ်လုပ်မှုကို တိုက်ရိုက်လုပ်ဆောင်ခြင်း

စက်ရုံထုတ်လုပ်မှုများကို အဆင်ပြေစွာ လည်ပတ်နေစေရန် အခက်အခဲဖြစ်စေသည့် အပူပိုင်းဒေသများတွင် စိုထိုင်းဆသည် အမြဲတမ်းရှိနေခြင်းကို တွေ့ရပါသည်။ ထို့ကြောင့် စိုစွတ်မှုကိုခံနိုင်ရည်ရှိသော DTF ဖလင့်များသည် အထူးအရေးပါပါသည်။ ထုတ်လုပ်သည့်စက်ပစ္စည်းများကို စိုစွတ်မှုကြောင့် ဖြစ်ပေါ်သော အနှောက်အယှက်များကို ကြုံတွေ့ရခြင်းမရှိဘဲ စက်ရုံများအနေဖြင့် ထုတ်လုပ်မှုကို ဆက်လက်လုပ်ဆောင်နိုင်သည့် ပစ္စည်းများဖြစ်ပါသည်။ တောင်ပိုင်းရှိ ထုတ်လုပ်သူအချို့သည် ထုတ်လုပ်မှုပမာဏကို ၂၅% ခန့်တိုးမြှင့်နိုင်ခဲ့ပါသည်။ ထိုနည်းပညာကို အသုံးပြုပြီးနောက်ပိုင်းတွင် စက်ပစ္စည်းများသည် စိုစွတ်မှုကြောင့် ပျက်စီးမှုမရှိတော့သောကြောင့် စုစုပေါင်းစွမ်းဆောင်ရည်မှာ ပိုမိုကောင်းမွန်လာပါသည်။ ထုတ်ကုန်များကို အချိန်မှန်စွာ တင်ပို့နိုင်ခြင်းကြောင့် ဖောက်သည်များသည် ပြန်လည်ဝယ်ယူသူများအဖြစ် အမှတ်ရကြပါသည်။ စိုစွတ်မှုများသည့် ဒေသများတွင် လုပ်ငန်းများအနေဖြင့် ထိုကဲ့သို့ ကာကွယ်ပေးသော ဖလင့်များကို ရင်းနှီးမြှုပ်နှံခြင်းသည် ငွေကြေးစီးဆင်းမှုအတွက်သာမက ဖောက်သည်များနှင့် ရင်းနှီးသောဆက်ဆံရေးအတွက်လည်း အကျိုးအမြတ်ရှိစေပါသည်။

ပြန်လည်ထုတ်လုပ်မှု အရေအတွက် ကျဆင်းမှုဖြင့် ကျွန်ကျေးဇူးရှိ

အစိုဓာတ်ခံနိုင်သည့် DTF ဖလင်များသည် အစိုဓာတ်ပြဿနာကြောင့် ဖိအပ်များကို ပြန်လည်စီမံရန် လိုအပ်မှုကို လျော့နည်းစေပြီး အချိန်ကြာလာသည့်အခါ ငွေကုန်သက်သာစေပါသည်။ ဖိအပ်များသည် အကြိမ်ပေါင်းများစွာ ပြန်လည်စတင်မှု မလိုအပ်တော့သောအခါ စက်ရုံများသည် လည်ပတ်မှုစရိတ်နည်းပြီး နေ့စဉ်ထုတ်ကုန်ပိုမိုထုတ်လုပ်နိုင်ပါသည်။ အချို့သုတေသနများအရ ကုမ္ပဏီများသည် အစိုဓာတ်ပြဿနာများကို ဖြေရှင်းခြင်းဖြင့် တစ်နှစ်လျှင် ထောင်ပေါင်းများစွာ ခြွင်တာနိုင်ကြောင်း ပြသပါသည်။ နာရီပေါင်းများစွာ ထုတ်လုပ်ရေးလိုင်းများကို လည်ပတ်နေသည့် ကြီးမားသည့်ထုတ်လုပ်သူများအတွက် အနားယူရသည့် အချိန်အတိုငယ်မျှဖြစ်ပေါ်လာပါက ငွေကြေးဆုံးရှုံးမှုများ ဖြစ်ပေါ်စေပါသည်။ ထို့ကြောင့် အစိုဓာတ်ကာကွယ်ရေးရန် ရင်းနှီးမြှုပ်နှံခြင်းသည် ဘတ်ဂျက်နှင့်အမြတ်အစွန်းကို တိုးတက်စေရန် အကျိုးဖြစ်ထုတ်ပေးပါသည်။ မှန်ကန်သည့် ရေကာကွယ်ရေးဖြေရှင်းချက်သည် လည်ပတ်မှုများကို အဆင်ပြေစေပြီး ငွေကုန်ကျစရိတ်ကိုလည်း သက်သာစေပါသည်။

Premium DTF Films ပ်ရောင်းတိုင်းအမျိုးအစား

Multi-Layer Protective Coatings အကြောင်း

အကောင်းဆုံး moisture proof DTF ဖလင်များသည် ပတ်ဝန်းကျင်မှ ကာကွယ်ပေးသည့် multi layer အလွှာများဖြင့် ပြုလုပ်ထားသည်။ အဘယ်ကြောင့် ဤအလွှာများသည် ထူးခြားသနည်း။ အကြောင်းမှာ ၎င်းတို့သည် အစွန်းအထင်းများကိုခုခံနိုင်ပြီး၊ စတက်တစ်စွာဖြစ်ပေါ်မှုကိုတားဆီးကာ ရေကိုတွန်းထုထားသောကြောင့် အမျိုးမျိုးသော စက်မှုလုပ်ငန်းများတွင် အသုံးဝင်ပါသည်။ စမ်းသပ်မှုများအရ multi layer ဖလင်များသည် အခြေခံ single layer ဖလင်များထက် ၆၀ ရာခိုင်နှုန်းအထိ ပိုမိုကြာရှည်သည်ဟု တွေ့ရပါသည်။ DTF ဖလင်များသည် နေ့စဉ်နှင့်အမျှ ခက်ခဲသော အခြေအနေများကိုခံနိုင်ရည်ရှိရန်လိုအပ်သည့် လက်တွေ့အခြေအနေများတွင် ဤကွာခြားမှုသည် အရေးပါသောအချက်ဖြစ်ပါသည်။

High-Humidity Pressing အောက်တွင် အပူချိန်စီမံကိန်း

အရည်အသွေးမြင့် ပရင်တာဖြင့် ပုံနှိပ်ထားသော ဖလင်များသည် စိုစွတ်သော အခြေအနေများတွင် ပြင်းထန်သော ပို၍ကောင်းမွန်စွာခံနိုင်ရည်ရှိပါသည်။ ဓာတ်ခွဲခန်းစမ်းသပ်မှုများအရ ၁၈၀ ဒီဂရီစင်တီဂရိတ်ကျော်အောင် ခံနိုင်ရည်ရှိပြီးနောက်တွင်မှသာ အသွေးအရောင်ပျက်စီးခြင်းများကို တွေ့ရပါသည်။ ဤပစ္စည်းများသည် ဖိအားအောက်တွင် တည်ငြိမ်နေသည့်အတွက် ပုံနှိပ်ထားသောပစ္စည်းများတွင် ပိုမိုကောင်းမွန်သော အရောင်ထုတ်လုပ်မှုနှင့် အသားအများအတွက် ပိုမိုရှင်းလင်းသော အသေးစိတ်အချက်များကို ပေးစွမ်းပါသည်။ ထို့အပြင် ပုံပျက်ခြင်း သို့မဟုတ် အလွှာလိုက်ခြင်းမပြုဘဲ ပိုမိုကြာရှည်ခံသော ထုတ်ကုန်များကို ထုတ်လုပ်ပေးပါသည်။ စားစပ်ပစ္စည်းစက်ရုံများ သို့မဟုတ် ထုပ်ပိုးစက်ရုံများကဲ့သို့သော နေရာများတွင် ထုတ်လုပ်ရေးလိုင်းများကို လည်ပတ်နေသော စီးပွားရေးလုပ်ငန်းများအတွက် အပူချိန်ခံနိုင်ရည်ရှိမှုသည် အရာရာတွင် ကွာခြားမှုကိုဖြစ်စေပါသည်။ ထို့အပြင် စီးပွားရေးလုပ်ငန်းများအတွက် အရေးကြီးသော ထုတ်လုပ်မှုအဆင့်များအတွင်း ပစ္စည်းများပျက်စီးမှုကြောင့် စက်များကို ရပ်တန့်မှုများကို ကာကွယ်ပေးပါသည်။

ပေါ်ဒါမ်အသုံးပြုမှုအတွက် အန္တာရှင်ခြင်း

DTF ဖလင်များအား စိုထိုင်းစေသော အင်တီစတက်တစ် အင်းစိန်များထည့်ခြင်းသည် ပြင်ပပြုလုပ်ရာတွင် ကောင်းမွန်သော ရလဒ်များရရှိရန်နှင့် မှုန့်ပုံစံဖြင့် ဖုံးအုပ်ပေးသည့်အခါတွင် အရာကြီးဖြစ်သည်။ အင်တီစတက်တစ် ဂုဏ်သတ္တိများမရှိပါက ပြုလုပ်စဉ်အတွင်း စတက်တစ်လျှပ်စစ်များ စုပုံလာပြီး မှုန့်ဖုံးအုပ်မှုများ နေရာအနှံ့အပြားဖြစ်ပေါ်စေပြီး ပုံနှိပ်ထုတ်ဝေမှု၏ အရည်အသွေး အနိမ့်ဆုံးဖြစ်စေသည်။ အင်တီစတက်တစ် ဖလင်များသို့ ပြောင်းလဲအသုံးပြုခြင်းဖြင့် မျက်နှာပြင်များပေါ်တွင် မှုန့်များ ဖြန့်ကျဲမှု ပိုကောင်းမွန်လာကြောင်း လေ့လာမှုအချို့က ပြသထားသည်။ အခြေအနေပေါ်မူတည်၍ ပုံမှန်အားဖြင့် ၃၀ ရာခိုင်နှုန်းခန့် တိုးတက်မှုရရှိနိုင်သည်။ ပိုကောင်းမွန်သော တူညီမှုများသည် ပယ်ချခံရသော ပုံနှိပ်မှုများနှင့် နောင်တွင် ဖြစ်ပေါ်လာမည့် အကျိုးဆက်များကို လျော့နည်းစေသည်။ ထုတ်လုပ်သူများက ဤပြောင်းလဲမှုကို အကောင်အထည်ဖော်ပြီးနောက် သူတို့၏ ထုတ်ကုန်များ၏ အရည်အသွေးတွင် သိသာထင်ရှားစွာ တိုးတက်မှုရှိကြောင်း အစီရင်ခံထားပြီး စားသုံးသူများက အရင်ကကြုံတွေ့ခဲ့ရသော ချို့ယွင်းချက်များကို အမှန်အကန် သိပ်မသတိထားမိတော့ပါ။

အောက်ချိန်ပြားမှုကို ကာကွယ်ရန် လိုအပ်သော အသုံးပြုမှုအခြေအနေများ

ကမ်းရိုးဒေသတွင် ပစ္စည်းပြုလုပ်ရေးအဖွဲ့

ကမ်းရိုးတန်းများရှိ စားသုပ်စက်ရုံများသည် အများအားဖြင့် အထည်အထုပ်အရည်အသွေးကို ပျက်ပြားစေသည့် အစိုဓာတ်များပြားမှုနှင့် ရင်ဆိုင်နေရပါသည်။ ထုတ်လုပ်သူများအတွက် နေ့စဉ်ပြဿနာဖြစ်နေသည့် အစိုဓာတ်ခုခံနိုင်သော DTF ဖလင့်များသည် အခြေခံကိရိယာများဖြစ်လာပါသည်။ ပုံမှန်အစိုဓာတ်ပြဿနာများကို ပိုမိုဆိုးရွားစေသည့် ဆားငံလေကို ခံနိုင်ရည်ရှိသည့် ဒေသများတွင် ထိုကာကွယ်ပေးသော အလွှာများသည် အလွန်ထိရောက်မှုရှိပါသည်။ ကမ်းရိုးတန်းရှိ စက်ရုံများတွင် ထိုဖလင့်များတပ်ဆင်ပြီးနောက် ထုတ်လုပ်မှုလိုင်းမှ အပ်ယောင်းထုတ်ကုန်များ လျော့နည်းလာခြင်းနှင့် ထုတ်လုပ်မှုလုပ်ငန်းစဉ်များ ပိုမိုချောမွေ့လာခြင်းတို့ကို တွေ့ရပါသည်။ အများစုအတွက် စျေးသက်သာမှုသည် ထိုဖလင့်များကို အသုံးပြုရန် တန်ဖိုးရှိစေပါသည်။ ထိခိုက်မှုများကို ကာကွယ်ပေးခြင်းထက်ပို၍ ထုတ်လုပ်မှုအတွင်း ထိုဖလင့်များသည် လုပ်ငန်းစဉ်များကို ပိုမိုမြန်ဆန်စေပြီး ပင်လယ်နီးနားရာတွင် ရေစိုထိုင်းများနှင့် ရင်ဆိုင်နေရသည့် အခြေအနေများကို ကောင်းမွန်စွာဖြတ်သန်းနိုင်စေပါသည်။

မွီးဆိုင်ဒေသများတွင် အခေါ်အဝေါ်ထုတ်လုပ်ရေးပြဿနာများ

မုန်တောင်ရာသီအတွင်း စိုထိုင်းဆ ပြောင်းလဲမှုများကြောင့် ထုတ်လုပ်မှုတွင် တည်ငြိမ်မှုမရှိတော့ပဲ စက်ရုံများအတွက် စိတ်ပူစရာဖြစ်နေပါသည်။ ထိုသို့အခါတွင် စိုထိုင်းဆခံ DTF ဖလင့်များက အထောက်အကူဖြစ်စေပါသည်။ အပြင်ဘက်တွင် မုန်တောင်သည် များစွာရွာသည့်အခါတွင်ပင် ထုတ်လုပ်မှုကို တည်ငြိမ်စေပါသည်။ ထိုဖလင့်များကို အသုံးပြုသည့်စက်ရုံများမှ မုန်တောင်ရာသီကာလအတွင်း ထုတ်လုပ်မှုကို တားစီးခြင်းမရှိဘဲ အလုပ်လုပ်နိုင်သည်ဟု အစီရင်ခံထားပါသည်။ ထို့အပြင် စာရင်းဇယားများကလည်း ထောက်ပံ့ပေးပါသည်။ စက်ရုံအချို့ကို စုစည်းခဲ့သည့်အခါတွင် စိုထိုင်းဆခံ ပစ္စည်းများကို အသုံးပြုပြီးနောက် မုန်တောင်ရာသီတွင် ထုတ်လုပ်မှုတွင် ၂၅ ရာခိုင်နှုန်းခန့် တိုးတက်မှုရှိခဲ့ပါသည်။ ထုတ်လုပ်မှုကို ဆက်လက်လုပ်ဆောင်နိုင်ခြင်းအပြင် စနစ်များကို ပိုမိုခိုင်မာစေရန် ဖလင့်များက အကူအညီပေးပါသည်။ ထုတ်လုပ်သူများသည် သဘာဝတရား၏ အခက်အခဲများကို ကြိုတင်ပြင်ဆင်နိုင်ပြီး ရာသီဥတုအခြေအနေများကို ထိရောက်စွာ ကျော်လွှားနိုင်ပါသည်။

အပြင်ပိုင်းအတွက် ကြီးမားသော ပုံစံဖြင့် ရောင်းမှု

ပြင်ပတွင်ဝတ်ဆင်ရမည့်အဝတ်အစားများအတွက် ပုံနှိပ်ထုတ်ဝေမှုကိစ္စများတွင် အခြားသူများထက် ပို၍ဂရုစိုက်သူများမှာ အတွင်းပိုင်းတွင် အဝတ်အစားများထုတ်လုပ်သည့်သူများဖြစ်ပါသည်။ အပြင်ဘက်တွင် အသုံးပြုသည့်အခါတွင် မိုးရေနှင့် အခြားသဘာဝအခြေအနေများကိုခံနိုင်ရည်ရှိသည့် DTF ဖလင့်များသည် ပုံနှိပ်မှုများကို ကောင်းမွန်စွာထိန်းသိမ်းပေးနိုင်ပါသည်။ ဤအထူးဖလင့်များသည် မိုးရေကိုခံနိုင်ရည်ရှိမှုမှသည် နေရောင်ခြည်နှင့် အပူချိန်အလွန်အကျွံများကိုခံနိုင်ရည်ရှိပြီး ပုံမှန်ပုံနှိပ်မှုများကို ရက်အတန်ကြာပျက်စီးစေနိုင်သည်။ အပြင်ဘက်တွင်အသုံးပြုသည့်ပစ္စည်းများကို ထုတ်လုပ်သည့်ထုတ်လုပ်သူများသည် မိုးရေကိုခံနိုင်သည့်ပုံနှိပ်မှုနည်းပညာသည် သူတို့၏ မိမိတိုင်းပြည်အမှတ်တရများကို မြှင့်တင်ပေးပြီး ဖောက်သည်များကိုပြန်လည်ဝယ်ယူစေသည်ကို တွေ့ကြပါသည်။ ထို့ကြောင့် အပြင်ဘက်တွင်ဝတ်ဆင်သည့်အဝတ်အစားများထုတ်လုပ်သည့် အဓိကကစားသမားများသည် မိုးရေကိုခံနိုင်သည့်ဖလင့်များကို စံပြစွာအသုံးပြုကြပြီး လေ၊ မိုးနှင့်နေရောင်ခြည်တို့၏ ထိတွေ့မှုကို တစ်လအကြာတွင်ပင် ထတ်ကုန်များကို တောက်ပစွာနှင့် ဖတ်ရှုနိုင်သည့်အတိုင်းထိန်းသိမ်းပေးနိုင်ပါသည်။

FAQ အပိုင်း

DTF ရောင်းမှုများတွင် ရေပျောက်မှုသဘာဝဆိုသည်မှာ ဘာလဲ?

DTF ဖিলံများ၏ hygroscopic သဘောတူညီချက်ဟာ အရေပြားကို ဆင်းယူနှင့် ထိန်းသိမ်းခြင်းရှိစေသည့် လုပ်ဆောင်ချက်ကို ဆိုလိုသည်။ ဒီဂုဏ်သည် ပုံမှန်အရင်းအမြစ်များ၏ လုပ်ဆောင်ချက်ကို သက်ရောက်နိုင်ပြီး ထို့ကြောင့် တောင်းဆိုထားသော substrates နှင့် inks ကို ရွေးချယ်ရန် အရေးကြီးဖြစ်သည်။

DTF ဖিলံများအတွက် အရေပြားကို ကန့်သတ်သည့်အခါ ink bleeding ကို ဘယ်လိုလျှင် လျော့နည်းစေသနည်း။

အရေပြားကို ကန့်သတ်သည့် DTF ဖিলံများသည် hydrophobic barriers ကို အသုံးပြု၍ အရေပြားကို ဝိုင်းထွက်စေပြီး ပုံမှန်အရင်းအမြစ်များ၏ သဘောတူညီချက်နှင့် vividness ကို မြင့်တင်သော ပတ်ဝန်းကျင်များတွင် ထိန်းသိမ်းနိုင်သည်။

Moisture-proof DTF ဖিলံများကို အသုံးပြုလျှင် ဘယ်လိုလုပ်ငန်းဆိုင်ရာ efficiencies တွေရရှိနိုင်သလဲ။

လုပ်ငန်းဆိုင်ရာ efficiencies မှာ အရေပြားကြောင့် ရှုံးထားသော wastes ကို လျော့နည်းစေခြင်း၊ tropical ပတ်ဝန်းကျင်များတွင် ထုတ်လုပ်မှုလုပ်ငန်းများကို ပိုမို streamlining ခြင်း၊ နည်းပြီး ပြန်လည်တည်ဆောက်ရန် ကျွန်းသော costs ကို သိမ်းဆည်းခြင်းတို့ဖြစ်သည်။

Moisture-proof DTF ဖိုင်များဟာ pressing အတွင်းတွင် high temperatures ကို မျှော်မျှော်နိုင်ပါသလား။

ဟုတ်ပါသည်၊ အရည်အသွေးမြင့် စိုထိုင်းစားခံ DTF ဖလင့်များသည် အပူချိန် ၁၈၀ ဒီဂရီစင်တီဂရိတ်ထက် ပိုမိုခံနိုင်ပြီး စွမ်းဆောင်ရည်ကို ထိခိုက်စေခြင်းမရှိဘဲ အပူဓာတ်များသော ပိုင်းခြင်းလုပ်ငန်းများတွင် အပူချိန်ကို တည်ငြိမ်စေထားနိုင်ပါသည်။

DTF ဖিলံများတွင် အန္တရာယ်လှုပ်ရှားမှု အခြေအနေများက ဘာအတွက် အရေးတိုးလဲ?

DTF ဖিলံများတွင် အန္တရာယ်လှုပ်ရှားမှုသည် အီလက်ထရိုစတတ်ဒစ်ခားဂိုဏ်း(ESD)ကို ကန့်ကွက်ပြီး ပိုင်းများ၏ မကြားမှုကို ဖြစ်ပေါ်စေရန် ကာကွယ်ပြီး၊ ပုံသွင်းသော အရည်အချင်းကို ကိုက်ညီစေပြီး ဆိုင်းပြီးမှုကို နည်းသို့ ဖြေရှင်းပါသည်။

DTF ဖিলံများတွင် ရေကို ကာကွယ်နိုင်သော အခြေအနေများက ဘယ်နေရာများတွင် အထောက်အကူပြုသည်?

ရေကို ကာကွယ်နိုင်သော DTF ဖিলံများသည် ကမ်းရိုးတွင် အစုံအဆောင်များ၊ မွေးရာရေသီးသန့်ဒေသများတွင် အလုပ်လုပ်သော စျေးဝယ်မှုများတွင် အထောက်အကူပြုပြီး အပြင်ပိုင်းအတွက် အကြီးမားသော ပုံသွင်းမှုအတွက် အရောင်းအဝယ်အတွက် အခြေအနေများကို ကာကွယ်ပေးပါသည်။

အကြောင်းအရာများ

- ရေပြင်မှုသည် DTF ဖিလံ၏ အလုပ်ဆောင်မှုကိုဘယ်လိုသက်ရောက်သနည်း

- ရေပြင်မှုကို ကန့်သတ်သော DTF ရောင်းပိုဒ်၏ အမြဲတမ်းသော အသုံးအဆင်များ

- လုပ်ငန်းစဉ်မြင်မြင်သာသာမှုတွင် ပြင်ဆင်မှုများ

- Premium DTF Films ပ်ရောင်းတိုင်းအမျိုးအစား

- အောက်ချိန်ပြားမှုကို ကာကွယ်ရန် လိုအပ်သော အသုံးပြုမှုအခြေအနေများ

-

FAQ အပိုင်း

- DTF ရောင်းမှုများတွင် ရေပျောက်မှုသဘာဝဆိုသည်မှာ ဘာလဲ?

- DTF ဖিলံများအတွက် အရေပြားကို ကန့်သတ်သည့်အခါ ink bleeding ကို ဘယ်လိုလျှင် လျော့နည်းစေသနည်း။

- Moisture-proof DTF ဖিলံများကို အသုံးပြုလျှင် ဘယ်လိုလုပ်ငန်းဆိုင်ရာ efficiencies တွေရရှိနိုင်သလဲ။

- Moisture-proof DTF ဖိုင်များဟာ pressing အတွင်းတွင် high temperatures ကို မျှော်မျှော်နိုင်ပါသလား။

- DTF ဖিলံများတွင် အန္တရာယ်လှုပ်ရှားမှု အခြေအနေများက ဘာအတွက် အရေးတိုးလဲ?

- DTF ဖিলံများတွင် ရေကို ကာကွယ်နိုင်သော အခြေအနေများက ဘယ်နေရာများတွင် အထောက်အကူပြုသည်?