How Moisture Affects DTF Film Performance

The Science of Moisture Absorption in Printing Materials

The way moisture gets absorbed really matters for how well Direct-to-Film (DTF) printing works. When film takes in water from the air, it changes both how the material feels and what happens chemically inside, which can mess up the final print quality. Research shows different materials soak up moisture at varying rates. Some plastics actually take in around 10% of their own weight when exposed to humidity, and this makes a big difference in how prints turn out. The term hygroscopic describes this moisture attracting behavior seen in many DTF films. Knowing about this property helps printers pick better materials and matching inks, making the whole printing operation run smoother without unexpected problems down the line.

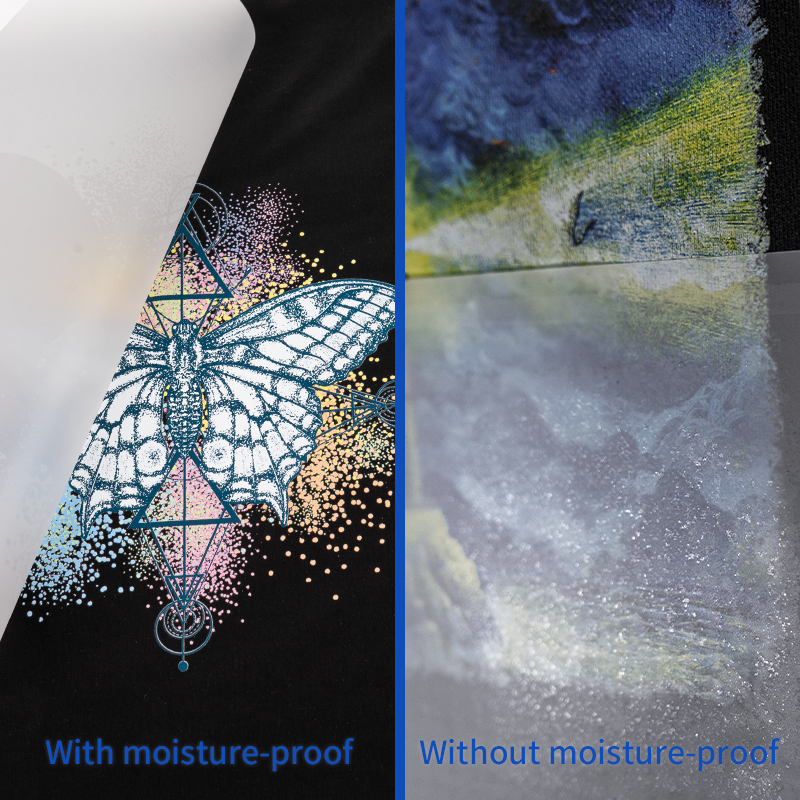

Common Humidity-Related Defects in DTF Transfers

Moisture is a real headache for DTF transfers, especially when it comes to ink bleeding problems. When this happens, printed images lose their sharpness and fine details just don't come through properly anymore. The trouble doesn't stop there either. Ghosting effects and partial transfers become common headaches too, since high humidity basically messes with how well the ink sticks to surfaces. According to what we see in the field, around 30% of all rejected prints in damp conditions trace back to these very issues. That's why keeping control over ambient moisture remains so critical throughout the manufacturing process if we want to avoid these costly quality problems down the line.

Impact on Ink Curing and Adhesion Processes

The amount of moisture present really affects how well ink cures and sticks to materials during DTF printing operations. When there's too much moisture around, the curing process gets messed up, leading to poor adhesion and prints that don't last as long as they should. Some studies show that printers need to tweak their curing temps based on what the humidity meter says, something that definitely impacts when jobs get completed. For shops working in areas where humidity runs high, keeping track of temperature and moisture levels becomes absolutely essential if they want those inks to stick properly. Getting climate control right isn't just nice to have it's actually what makes the difference between good prints and ones that fall apart after a few washes.

Moisture-Proof DTF Film Advantages for Print Quality

Preventing Ink Bleeding Through Hydrophobic Barriers

DTF films that resist moisture work really well at stopping ink from bleeding all over the place because they come with special coatings that push water away. The way these coatings work helps keep printed images looking sharp and colorful instead of getting blurry. Most people who print regularly know how frustrating it gets when regular films just cant handle the moisture and everything runs together. Some tests done recently found that these moisture resistant films cut down on ink bleeding problems by around half compared to normal ones. That kind of improvement makes a big difference for anyone working in places where there's always some humidity hanging around, like printing shops near coastal areas or in tropical climates where dampness seems to be everywhere.

Maintaining Film Flatness During Heat Press Operations

Moisture proof DTF films really shine because they stay flat during those heat press sessions. When working with these materials, maintaining flatness makes all the difference between good transfers and great ones. What sets them apart is how their construction actually stops surfaces from buckling up, something that happens way too often when humidity gets out of hand. With this kind of stability, the material applies evenly over whatever surface it touches. That matters a lot for getting clean transfers and cutting down on wasted product during runs. Less warping means fewer rejects overall, so printers can get through jobs faster without constantly stopping to fix problems.

Color Consistency Across Variable Climate Conditions

Moisture proof DTF films hold their colors really well no matter what kind of weather they face, which makes them great for just about anywhere. Some research shows these films actually keep colors looking true about 40% better than regular ones when things get tough out there. For companies that care deeply about how their stuff looks, this matters a lot since colors need to stay consistent for brand recognition. When colors don't shift around, brands can count on getting those bright, accurate shades right every time. This helps products stand out visually and sell better in stores or online, something most businesses would agree is pretty important.

Operational Efficiency Improvements

Reducing Waste From Humidity-Induced Rejects

Moisture proof DTF films really cut down on all that wasted material when prints get rejected because of humidity issues. Manufacturers report seeing their rejection rates drop by around 35% after switching to these special films. The numbers tell a story most companies care about money saved at the end of the day. Less scrap means higher profits and lower costs across the board. When businesses start looking at their bottom line, they quickly realize that cutting waste isn't just good for the environment but makes sense financially too. In today's tough markets where everyone is fighting for every dollar, smart companies know that reducing waste gives them a real edge over competitors who aren't paying attention to these details.

Streamlining Production in Tropical Environments

Keeping production running smoothly gets tricky in tropical regions where humidity just won't quit. That's where moisture proof DTF films really shine. These materials let factories keep going without all those annoying stoppages caused by dampness messing with equipment. Some manufacturers down south saw their output jump around 25% after switching to this tech. And it makes sense too. When machines don't break down from moisture damage, everything runs better. Products get shipped on time, which means happy customers who stick around for repeat business. For companies in humid zones, investing in these protective films pays off both in terms of cash flow and long term relationships with clients.

Cost Savings Through Fewer Press Resets

DTF films that resist moisture help cut down on how often presses need to be reset because of dampness issues, which saves money in the long run. When presses don't reset so frequently, factories spend less on running costs and produce more goods each day. Some studies show companies can actually save thousands every year just by fixing these moisture problems. For big manufacturers running non-stop production lines, even short periods of downtime mean real cash losses. That's why investing in moisture protection makes sense both from a budget standpoint and for bottom line growth. The right waterproofing solution keeps operations running smoothly while still being good for the wallet.

Technical Specifications of Premium DTF Films

Multi-Layer Protective Coatings Explained

The best moisture proof DTF films come with those fancy multi layer coatings that really boost protection from all sorts of environmental nasties. What makes these coatings stand out? They resist scratches, fight static buildup, and keep water at bay, which is why they work so well across different industries. Take a look at the numbers too: tests show multi layer films last about 60% longer than basic single layer options when put through their paces. That kind of difference matters a lot in real world situations where DTF films need to hold up against tough conditions day after day.

Thermal Stability Under High-Humidity Pressing

High quality printing films hold up really well when exposed to intense heat pressing in humid conditions. Lab tests show they can handle over 180 degrees Celsius before showing any signs of degradation. The fact that these materials stay stable under stress means better color reproduction and sharper details on printed items. Plus, products made with them tend to last longer without warping or peeling. For businesses running production lines in places like textile factories or packaging plants, this kind of temperature resistance makes all the difference. It keeps machines running smoothly without unexpected shutdowns caused by material failure during critical manufacturing stages.

Anti-Static Properties for Powder Application

Adding anti-static features to moisture proof DTF films makes all the difference when it comes to getting good results from substrate prep work and applying powder coatings properly. Without these anti-static qualities, static electricity builds up during processing, leading to patchy powder coverage and poor print quality overall. Some studies have shown that switching to anti-static film options actually boosts how evenly the powder gets applied across surfaces, sometimes improving consistency around 30% give or take depending on conditions. Better consistency means fewer rejected prints and less waste down the line. Manufacturers who've made the switch report noticeable improvements in their finished products, with customers hardly noticing any defects anymore compared to what they used to see before implementing this change.

Application Scenarios Demanding Moisture Resistance

Coastal Textile Manufacturing Facilities

Textile factories along coastlines often struggle with excessive humidity that messes up fabric quality. For manufacturers dealing with this issue daily, moisture resistant DTF films have become almost essential equipment. These protective layers work wonders in areas affected by salty sea air, which makes regular moisture problems even worse. Real world experience shows that when coastal plants install these films, they see fewer defective products coming off the line while their production runs smoother too. The cost savings alone make them worth it for most businesses. Beyond just preventing damage, these films actually help speed things up during manufacturing, so operations run better despite all the damp conditions that come with being near the ocean.

Seasonal Production Challenges in Monsoon Regions

Textile makers in areas hit hard by monsoons face real headaches because of all those humidity swings throughout the season. These changes just throw a wrench into stable production. That's where moisture proof DTF films come in handy. They basically keep things running smoothly even when it rains cats and dogs outside. Factories using these films report being able to maintain their usual output without getting sidelined by wet weather. Some actual numbers back this up too. A recent survey of several mills showed around a 25% jump in productivity during rainy months once they started using moisture resistant materials. Beyond just keeping operations going, these films actually help build stronger systems overall. Manufacturers find themselves better prepared for whatever Mother Nature throws at them while still managing to get work done efficiently despite challenging climate conditions.

Large-Format Printing for Outdoor Apparel

When it comes to big format printing for stuff worn outside, nobody cares more about print quality lasting through rough conditions than those actually making clothes for outdoors. Moisture proof DTF films really make all the difference when trying to keep prints looking good despite whatever Mother Nature throws at them. These special films protect against everything from sudden downpours to harsh sunlight and extreme temps that can ruin regular prints within days. Most manufacturers who work with outdoor gear know this firsthand after seeing how waterproof printing tech boosts their brand image and keeps customers coming back for more. That's why pretty much every serious player in the outdoor apparel game now uses these moisture resistant films as part of standard practice, ensuring their products stay vibrant and legible even after months of exposure to wind, rain, and sun.

FAQ Section

What is hygroscopic nature in DTF films?

The hygroscopic nature of DTF films refers to their tendency to attract and retain moisture. This property can affect the performance of the printing materials, making it crucial to select the right substrates and inks.

How do moisture-proof DTF films reduce ink bleeding?

Moisture-proof DTF films reduce ink bleeding by utilizing hydrophobic barriers that repel moisture, effectively maintaining the clarity and vividness of prints even in high humidity environments.

What operational efficiencies are gained by using moisture-proof DTF films?

Operational efficiencies include reduced waste from humidity-induced rejects, streamlined production processes, especially in tropical environments, and cost savings through fewer press resets.

Can moisture-proof DTF films withstand high temperatures during pressing?

Yes, premium moisture-proof DTF films can maintain thermal stability under high-humidity heat-pressing operations, withstanding temperatures exceeding 180°C without compromising performance.

Why are anti-static properties important in DTF films?

Anti-static properties in DTF films prevent electrostatic discharge that can cause uneven powder distribution, thereby maintaining consistency in print quality and minimizing defects.

Where are moisture-proof DTF films particularly beneficial?

Moisture-proof DTF films are particularly beneficial in coastal textile manufacturing facilities, monsoon regions, and for large-format printing for outdoor apparel, providing resilience against challenging climates.

Table of Contents

- How Moisture Affects DTF Film Performance

- Moisture-Proof DTF Film Advantages for Print Quality

- Operational Efficiency Improvements

- Technical Specifications of Premium DTF Films

- Application Scenarios Demanding Moisture Resistance

-

FAQ Section

- What is hygroscopic nature in DTF films?

- How do moisture-proof DTF films reduce ink bleeding?

- What operational efficiencies are gained by using moisture-proof DTF films?

- Can moisture-proof DTF films withstand high temperatures during pressing?

- Why are anti-static properties important in DTF films?

- Where are moisture-proof DTF films particularly beneficial?