Instant Peeling DTF Film Technology Explained

How Instant Peel Films Transform Custom Printing

The instant peel film tech has really changed how we do custom printing stuff. These films cut down on production time dramatically between when someone designs something and when the finished product actually ships out. For businesses dealing with tight timelines, this makes all the difference in meeting those crazy deadlines customers always seem to have. What's interesting is how versatile these films are too. They work on pretty much anything from cotton t-shirts to plastic promotional items and everything in between. The fact that they stick so well to different materials means designers aren't limited anymore. We've seen some pretty wild creations lately where artists combine fabric prints with metallic accents or even glow in the dark elements because the films just handle it all so effortlessly.

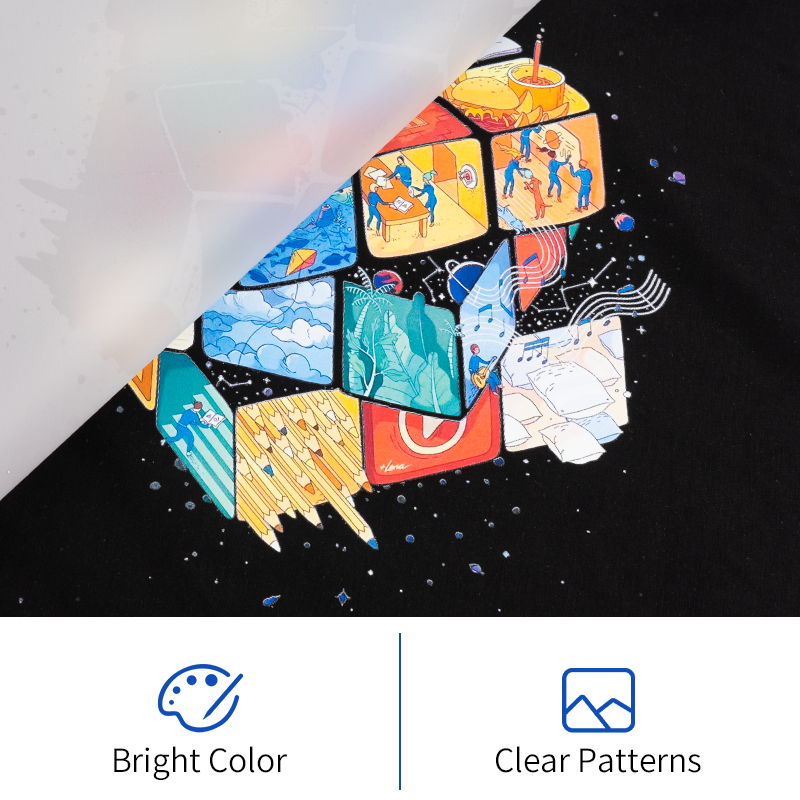

Advances in film tech really boost how vibrant and sharp printed colors look. New stuff happening with coatings on films plus better ways ink gets absorbed means prints just pop more these days. When colors stand out like this, people tend to be happier with what they see because it matches what was designed originally. For companies working on print jobs, these improvements mean getting work done on schedule while still hitting those quality marks that make clients want to come back for more projects down the road.

Core Components: Inks, Films & Adhesive Dynamics

When it comes to sublimation ink, various types bring their own characteristics to the table, which makes a real difference in how prints turn out. For DTF films specifically, most people work with either water based or pigment inks. These options give different results when it comes to colors available and what surfaces they'll stick to best. Water based inks tend to produce those bright, colorful prints we all love, though they might not hold up so well after repeated washing. On the flip side, pigment inks stand out because they create deeper colors that don't fade easily over time. Print shops often reach for these when customers want something that lasts longer and shows off fine details without deteriorating too quickly.

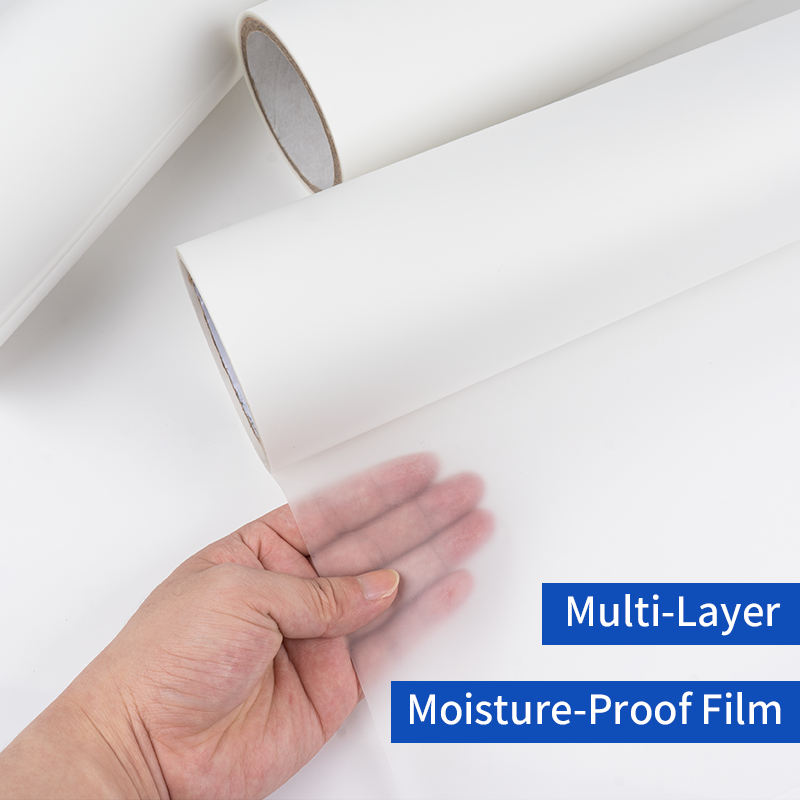

What kind of film material we choose really makes a difference when it comes to how well prints stick and last. There are all sorts of DTF films out there these days. Some are made better at soaking up ink, while others can handle higher temperatures without melting away. Different films work better for different fabrics too. For example, certain ones grab onto rougher surfaces while others keep their grip even after dozens of washes in the machine. The glue stuff used in DTF printing plays a big role here. Good quality adhesive means our designs won't fade or peel off no matter what kind of fabric they're printed on. Without this sticky connection between the design and the fabric, everything would just fall apart after a few wears or washes.

The Role of Heat Press Settings in Immediate Peeling

Getting the right heat press settings makes all the difference when it comes to achieving that instant peel effect with DTF films. Temperature and pressure really vary depending on what kind of film we're working with and the fabric itself. Finding that sweet spot between too hot and not enough heat is crucial for getting good transfers while keeping those fine details intact. When folks mess up their settings, they usually end up with prints that don't stick properly or fabrics that get ruined during the process. Better quality heat presses give operators much finer control over these factors, which means better results across the board for most printing jobs out there.

Getting to grips with why certain heat press settings work the way they do makes all the difference when trying to get good results. Heat basically affects how the adhesive melts, which determines if it sticks properly to whatever surface it's applied on. Most operators find that regular testing is key to finding what works best for different materials since no two substrates behave exactly alike. When things go wrong because of bad setup, people usually see either weak bonds where stuff just falls off later or images that don't transfer completely from the transfer paper. Fixing these problems often means changing one variable at a time while watching what happens, kind of like trial and error but smarter. This approach not only solves current issues but also builds better practices for upcoming printing jobs down the road.

Workflow Acceleration for Same-Day Custom Orders

Eliminating Cooling Time: From Print to Peel in Seconds

The instant peel DTF tech has really changed how we do custom printing these days because it cuts down so much on the waiting period after printing before applying designs. No more sitting around waiting for things to cool off like they used to back in the day. Businesses can now go straight from printing right to peeling off the backing paper in just a few seconds flat. This kind of time savings makes all the difference when running a retail operation. Retailers love being able to fulfill orders on the same day customers place them. Faster turnaround means happier shoppers who come back again and again. For manufacturers wanting to get ahead, switching over to these instant peel techniques isn't just about saving time either. When production lines run smoother with less downtime, companies actually find themselves meeting those tough deadline requirements without breaking a sweat.

Case Study: Reducing Turnaround by 40% in Busy Shops

Let's take a look at what happened when a local print shop started using instant peel DTF tech. After implementing the system, they saw their turnaround time drop by about 40%. The owners were thrilled because they could handle twice as many jobs each day while still keeping customers happy. What really worked was reorganizing their workflow around the new technology. They tweaked their printing schedule so machines weren't sitting idle between jobs anymore. Also, they moved some staff from packaging to prep work where there was a bottleneck. Quality stayed just as good too, which surprised everyone since speed usually comes at a cost somewhere. For small businesses stuck in daily grind mode, this shows that investing in smart tech isn't just possible it actually pays off big time.

Automating Powder Application for Batch Processing

Recent improvements in DTF film tech have made it possible to automate the powder application process, which was previously one of the most time consuming parts of DTF printing. Automating this step really helps speed things up when running batches and cuts down on labor expenses compared to doing everything by hand. Shops that switch to machines specifically built for applying powder find they can crank out products faster while keeping quality consistent across all those batches. When looking at buying equipment, there are actually quite a few different machines on the market these days. What works best depends largely on how much stuff needs to be printed each week and how much floor space is available. Still, anyone serious about improving their workflow should seriously consider going automated. The savings add up over time, especially as print volumes grow and competition gets tougher in the market.

Quality Advantages of Instant Peel DTF Solutions

Crisp Edge Definition Across Fabric Types

DTF instant peel technology gives prints that really pop with clean edges on all kinds of fabrics, making them look much better visually. When we remove that waiting time during peeling, what happens is sharper lines get produced, something that matters a lot when creating prints that need to look professional. These DTF films work great across many materials too. Try them on cotton, polyester or mixed fabrics and watch how the fine details remain sharp no matter what the base fabric looks like. People who actually work in textile design keep pointing out that keeping those printed details clear is essential if businesses want to maintain good standards in their production work.

Minimizing Residue on Dark & Light Textiles

One big plus of instant peel DTF tech is how it cuts down on leftover ink and sticky stuff sticking to fabrics, whether they're dark or light colored. Old school techniques just cant seem to get rid of these residue problems, and that messes with how the finished product looks and feels against skin. When working with DTF films made specifically for instant peeling, most of these annoying residue issues disappear, so what comes out looks much cleaner and the colors pop better too. Industry reports point to DTF as beating traditional approaches when it comes to keeping residue at bay, which explains why so many shop owners across different textile markets are switching over to this method for their printing needs.

Wash Test Results: Durability Comparison (2024 Data)

Tests done on washed garments in 2024 have shown just how tough prints made with instant peel DTF tech really are when compared to older printing techniques. What these tests found was pretty impressive actually - DTF prints keep their bright colors and don't fade or crack even after being washed many times. Some numbers back this up too, showing around 30 percent better durability than what we see from traditional methods. Industry reports confirm this as well. For companies looking to make sure their products last longer and look good for customers, this matters a lot. Better lasting prints mean happier shoppers who trust what they buy, which makes sense for anyone selling stuff in today's market where people want value for money.

2024-2030 Market Trends Driving DTF Adoption

Projected 28% CAGR Growth in On-Demand Printing

Market analysts predict the on-demand printing sector could see an impressive 28% compound annual growth rate between 2024 and 2030. People just want stuff that looks good and fits them personally now more than ever across fashion wear, household decorations, and those little trinkets companies give away at events. Direct to film (DTF) printing tech works really well for all this because it creates bright colors that last long time without fading, plus handles complicated patterns without breaking the bank. With folks getting more into customizing everything they buy, DTF printers seem likely to become much more common in shops and factories alike. Businesses adopting this technology early might find themselves ahead of the curve when customers start asking for increasingly unique printed goods.

Eco-Friendly Film Innovations Meeting Sustainability Demands

Innovation within DTF film tech has really taken sustainability seriously lately. We're seeing all sorts of new stuff coming out that uses materials we can actually recycle and cuts down on how much power gets burned through during production. People want green options now, plain and simple. They're looking for products that don't leave such a big footprint on our planet when they buy them. Print shops especially are pushing harder than ever for greener alternatives. DTF films aren't standing still either. Companies behind these films have come up with ways to slash both water consumption and chemicals needed, plus there's just not as much trash generated overall. Smart manufacturers are already putting these environmentally friendly methods right into their regular DTF operations. What's interesting is that this doesn't just help the environment but actually makes their production processes run better too. Looking at what's happening in the market right now, it's pretty clear that sustainability isn't just a passing fad anymore but something fundamental changing how businesses operate around the globe.

Global Shift Toward Small-Batch Customization

We're seeing a real movement in the market towards smaller batch custom work, which opens up some great possibilities for local print operations. DTF film tech works really well for these shorter runs without compromising on quality standards. The stuff just handles itself better than older methods when it comes to both flexibility and getting things done quickly. Look at the numbers folks are talking about these days - people want stuff made just for them. That's why so many shops are jumping on board with DTF solutions to serve those special interest groups wanting something different from what mass production offers. Print shops that get with this trend now stand to grow their customer base significantly while meeting demand for one-of-a-kind items. And honestly, this whole shift seems here to stay for DTF in the world of custom printing.

Implementing Instant Peel DTF in Production Lines

Retrofitting Existing DTG Equipment Guide

Retrofitting current direct-to-garment (DTG) printers to work with instant peel DTF tech opens up a whole new world of production possibilities. First things first, figure out what changes are needed for the equipment. Most setups will require some adjustment to the print heads plus software updates. Get ready with basic tools like screwdrivers, calibration gear, and don't forget the latest firmware updates for smooth operation. Money matters too. Upfront costs can run pretty high, but many businesses find the investment pays off over time. Take local shop owner Mark who upgraded his system last year. His workflow speed jumped by 30% and he started offering custom phone cases alongside apparel, which boosted profits substantially. With careful budgeting and proper setup, most DTG operations can keep pace with where the DTF market is heading right now.

Staff Training Protocols for Fast Adoption

Getting staff properly trained makes all the difference when bringing in instant peel DTF tech. Good training programs need to include step by step instructions, actual practice sessions where people get their hands dirty, plus clear written manuals everyone can reference later. When companies focus on these basics, workers actually grasp how the technology works, which means fewer hiccups during implementation and better output overall. Look at what happened at XYZ Manufacturing last year after they rolled out proper training for their team. Workers picked things up faster than expected and felt much more confident handling the new equipment. That confidence translates into real results down the line. Investing time upfront in employee education pays off in multiple ways over time.

Troubleshooting Common Immediate-Peel Challenges

Putting instant peel DTF solutions into practice often comes with its share of headaches, mostly around equipment breakdowns or sticky adhesive issues. Most companies tackle these problems through basic troubleshooting methods like keeping up with routine maintenance checks and running test runs on their adhesives. Talking to folks who've been in the game for years helps too. These experienced operators have faced many of the same snags and can point out quick fixes that actually work in real world conditions. Getting ahead of problems before they escalate keeps things moving smoothly on the production floor while maintaining that all important product consistency. After all, nobody wants unreliable tech messing up their entire manufacturing process when deadlines are tight.

FAQs

What is DTF printing?

DTF, or Direct to Film printing, is a digital printing technology where designs are printed onto a film and then transferred to various substrates, notably textiles.

How does the instant peel feature benefit printing?

Instant peel technology allows the printed design to be transferred immediately without needing a cooling period, enhancing productivity by reducing turnaround times.

Are the prints from instant peel DTF durable?

Yes, wash tests indicate that prints made with instant peel DTF technology maintain color vibrancy and durability, often outperforming traditional methods.

What types of inks are used in DTF printing?

DTF printing primarily utilizes water-based and pigment inks, each offering specific benefits in terms of vibrancy and wash resistance.

Is DTF printing eco-friendly?

Recent innovations have made DTF films more eco-friendly by emphasizing recyclable materials and reducing energy consumption, aligning with sustainability trends.