ত্রিকালে ছাঁটা ডিটিএফ ফিল্ম প্রযুক্তি ব্যাখ্যা

ইনস্ট্যান্ট পিল ফিল্মস কিভাবে কัส্টম প্রিন্টিং-এ রূপান্তর করে

ইনস্ট্যান্ট পিল ফিল্মের প্রযুক্তি আমাদের কাস্টম প্রিন্টিংয়ের কাজের ধরনটাই বদলে দিয়েছে। এই ফিল্মগুলি উৎপাদনের সময়কে অনেকটাই কমিয়ে দেয় কারণ কোনো কিছু ডিজাইন করার পর থেকে শুরু করে চূড়ান্ত পণ্যটি পাঠানোর মধ্যে এগুলি ব্যবহার করা হয়। যেসব ব্যবসায়িক প্রতিষ্ঠানে সময়সীমার চাপ থাকে, এগুলি সেই অসম্ভব সময়সীমা মেটাতে পার্থক্য তৈরি করে। এটি আকর্ষণীয়ও যে এই ফিল্মগুলি কতটা বহুমুখী। এগুলি সবকিছুতেই কাজ করে, কটনের টি-শার্ট থেকে শুরু করে প্লাস্টিকের প্রচারমূলক পণ্য পর্যন্ত। বিভিন্ন উপকরণের সঙ্গে এগুলি যেভাবে আঠালোভাবে লেগে থাকে তাতে ডিজাইনারদের আর কোনো সীমাবদ্ধতা থাকে না। সম্প্রতি আমরা অনেক অদ্ভুত সৃষ্টি দেখেছি যেখানে শিল্পীরা ফ্যাব্রিক প্রিন্টের সঙ্গে মেটালিক সজ্জা বা এমনকি আলোকবিহীন অবস্থায় আলো দেওয়া উপাদানগুলি মিশিয়ে ফেলছেন কারণ ফিল্মগুলি সেগুলি সহজেই সামলে নিচ্ছে।

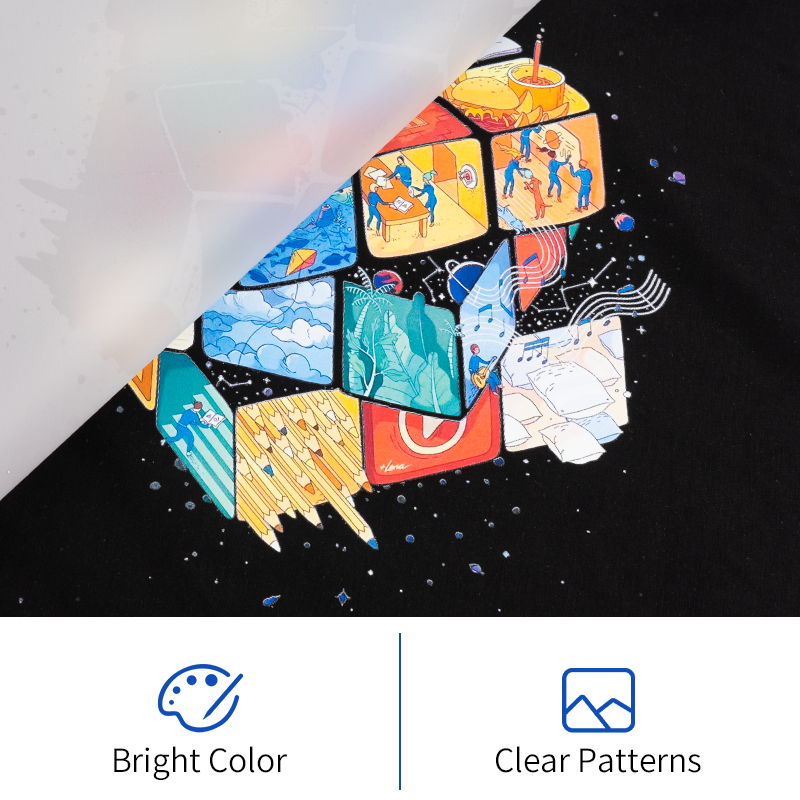

ফিল্ম প্রযুক্তিতে অগ্রগতি ছাপানো রংগুলি কতটা স্পষ্ট ও ধারালো দেখায় তা বাড়িয়ে দেয়। ফিল্মের ওপর আস্তরণ নিয়ে নতুন কাজ এবং আরও ভালো করে শোষিত হওয়া কালির নতুন পদ্ধতির কারণে আধুনিক ছাপাগুলি আগের চেয়ে বেশি স্পষ্ট দেখায়। যখন রংগুলি এমনভাবে চোখে পড়ে, তখন মানুষ সাধারণত দৃশ্যমান জিনিসটি দেখে খুশি হয়, কারণ এটি আসলে যা ডিজাইন করা হয়েছিল তার সঙ্গে মেলে। ছাপার কাজে নিয়োজিত প্রতিষ্ঠানগুলির জন্য এই উন্নতিগুলি বলে দাঁড়ায় যে তারা সময় মেনে কাজ করতে পারবে এবং সেই সঙ্গে মানের মাপকাটি পূরণ করতে পারবে যা গ্রাহকদের পুনরায় ভবিষ্যতে আরও প্রকল্পের জন্য ফিরিয়ে আনবে।

মৌলিক উপাদান: ইন্ক, ফিল্মস এবং আড়hesive ডায়নামিক

সাবলিমেশন স্যাঁক নিয়ে আসলে বিভিন্ন ধরনের নিজস্ব বৈশিষ্ট্য নিয়ে আসে, যা প্রিন্টগুলি কীভাবে তৈরি হয় তাতে পার্থক্য তৈরি করে। বিশেষ করে DTF ফিল্মের ক্ষেত্রে, অধিকাংশ মানুষ জলভিত্তিক বা রঞ্জক স্যাঁক ব্যবহার করে থাকেন। রং এবং কোন পৃষ্ঠে এগুলি ভালোভাবে লেগে থাকবে তার উপর এই বিকল্পগুলি ভিন্ন ফলাফল দেয়। জলভিত্তিক স্যাঁক সাধারণত উজ্জ্বল এবং রঙিন প্রিন্ট তৈরি করে, যদিও বারবার ধোয়ার পর এগুলি টেকসই হয় না। অন্যদিকে, রঞ্জক স্যাঁক গভীর রং তৈরি করে যা সময়ের সাথে ফ্যাকে যায় না। দীর্ঘস্থায়ী এবং বিস্তারিত মানের কাজের জন্য প্রিন্ট দোকানগুলি প্রায়শই এগুলি ব্যবহার করে থাকে।

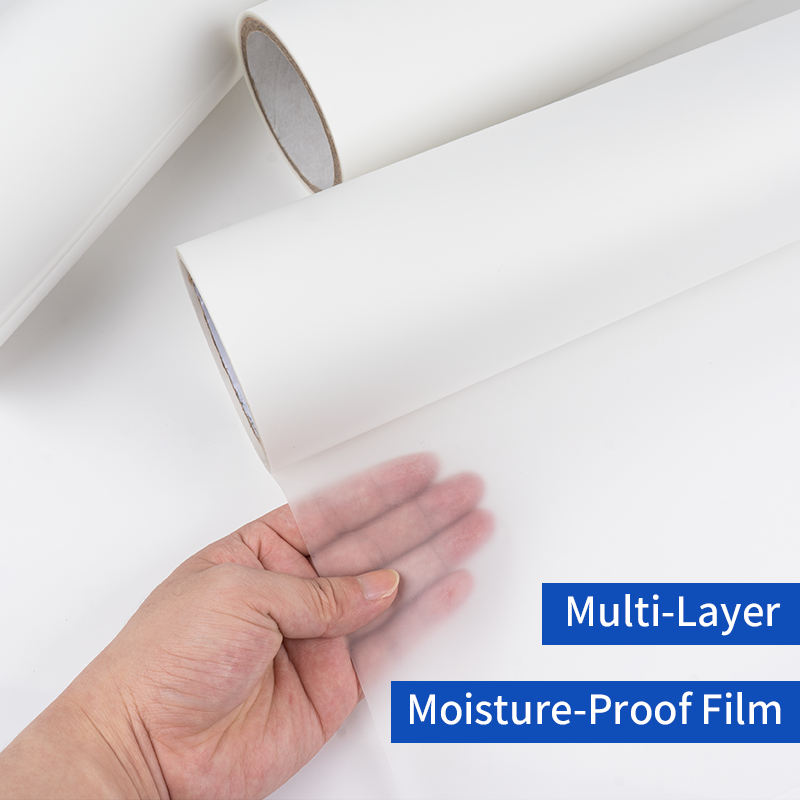

ফিল্মের ধরনটি আমরা কী বেছে নিচ্ছি তা প্রিন্টগুলি কতটা আঁটো ভাবে লেগে থাকে এবং কতটা স্থায়ী হয় তার ওপর অনেকখানি প্রভাব ফেলে। আজকাল বাজারে নানা ধরনের DTF ফিল্ম পাওয়া যায়। কিছু ফিল্ম কালি শোষণে ভালো হয়, আবার কিছু ফিল্ম গলে না যাওয়া পর্যন্ত উচ্চ তাপমাত্রা সহ্য করতে পারে। বিভিন্ন ধরনের কাপড়ের জন্য বিভিন্ন ফিল্ম ভালো কাজ করে। উদাহরণস্বরূপ, কিছু ফিল্ম খাঁজদার পৃষ্ঠের সঙ্গে ভালো আঁটো হয়ে যায়, আবার কিছু ফিল্ম মেশিনে অনেকবার ধোয়ার পরেও তাদের আঁটো ধরে রাখে। DTF প্রিন্টিং-এ ব্যবহৃত আঠালো পদার্থের এখানে অনেক ভূমিকা রয়েছে। ভালো মানের আঠা দিয়ে আমাদের ডিজাইনগুলি কোনো না কোনোভাবেই ফ্যাকে যাবে বা ছিঁড়ে যাবে না, যে ধরনের কাপড়েই ছাপা হোক না কেন। ডিজাইন এবং কাপড়ের মধ্যে এই আঠালো সংযোগ ছাড়া কেবলমাত্র কয়েকবার পরার বা ধোয়ার পরেই সবকিছু ভেঙে যাবে।

উষ্ণতা প্রেস সেটিংসের ভূমিকা তৎক্ষণাৎ ছিনুক করতে

ডিটিএফ ফিল্মগুলির সাথে সেই ইনস্ট্যান্ট পিল ইফেক্ট অর্জনের ক্ষেত্রে সঠিক হিট প্রেস সেটিংস সবকিছুর পার্থক্য তৈরি করে। তাপমাত্রা এবং চাপ আমরা যে ধরনের ফিল্ম এবং কাপড়ের সাথে কাজ করছি তার উপর নির্ভর করে প্রকৃতপক্ষে পরিবর্তিত হয়। খুব গরম এবং যথেষ্ট তাপ না থাকার মধ্যে সেই মিষ্টি জায়গাটি খুঁজে পাওয়া ছবি স্থানান্তরের জন্য ভালো ফলাফল পাওয়ার পাশাপাশি সেই ক্ষুদ্র বিবরণগুলি অক্ষুণ্ণ রাখার জন্য অপরিহার্য। যখন মানুষ তাদের সেটিংসগুলি ভুল করে, তখন তারা সাধারণত ছাপগুলি পায় যেগুলো ঠিকভাবে আটকে থাকে না অথবা প্রক্রিয়ার সময় কাপড়গুলি নষ্ট হয়ে যায়। ভালো মানের হিট প্রেসগুলি অপারেটরদের এই উপাদানগুলির উপর অনেক বেশি নিয়ন্ত্রণ দেয়, যার ফলে বেশিরভাগ ছাপার কাজের ক্ষেত্রে ভালো ফলাফল পাওয়া যায়।

নিশ্চিত হিট প্রেস সেটিংস কেন এমন কাজ করে তা বুঝতে পারা ভাল ফলাফল পাওয়ার জন্য সবথেকে বেশি গুরুত্বপূর্ণ। তাপ মূলত এটি নির্ধারণ করে যে কীভাবে আঠা গলে যায়, যার ফলে এটি কোনও পৃষ্ঠের সাথে সঠিকভাবে লেগে থাকে কিনা তা নির্ভর করে। অধিকাংশ অপারেটর বুঝতে পারেন যে নিয়মিত পরীক্ষা করা বিভিন্ন উপকরণের জন্য কী ভালো কাজ করে তা খুঁজে বার করার ক্ষেত্রে অপরিহার্য। যেহেতু দুটি উপাদান একই রকম আচরণ করে না। খারাপ সেটআপের কারণে যখন সমস্যা দেখা দেয়, তখন মানুষ সাধারণত দুর্বল বন্ধন দেখতে পায় যেখানে পরে জিনিসপত্র খুলে যায় বা ছবিগুলি সম্পূর্ণরূপে ট্রান্সফার কাগজ থেকে স্থানান্তরিত হয় না। এই সমস্যাগুলি সমাধানের জন্য প্রায়শই একসময়ে একটি পরিবর্তনশীল পরিবর্তন করা হয় এবং কী ঘটছে তা লক্ষ্য করা হয়, প্রায় পরীক্ষা-নিরীক্ষা করা ছাড়া বুদ্ধিমানের মতো। বর্তমান সমস্যার সমাধান করার পাশাপাশি এই পদ্ধতি ভবিষ্যতের প্রিন্টিং কাজের জন্য আরও ভালো পদ্ধতি তৈরি করে।

একই দিনের কাস্টম অর্ডারের জন্য কাজের প্রবাহ ত্বরিত করা

চালনা সময় বাদ দেওয়া: সেকেন্ডে প্রিন্ট থেকে পিল করা

ইনস্ট্যান্ট পিল ডিটিএফ প্রযুক্তি আমাদের কাস্টম প্রিন্টিংয়ের পদ্ধতিতে ব্যাপক পরিবর্তন এনেছে কারণ এটি ডিজাইন প্রয়োগের আগে প্রিন্ট করার পরে অপেক্ষা করার সময় অনেক কমিয়ে দিয়েছে। আগে যেমন প্রিন্ট করা শেষ হলে ঠান্ডা হওয়ার জন্য অপেক্ষা করতে হতো, এখন আর সেরকম হয় না। ব্যবসায়িক প্রতিষ্ঠানগুলো এখন প্রিন্ট করার পরপরই মাত্র কয়েক সেকেন্ডের মধ্যে ব্যাকিং পেপার খুলে ফেলতে পারে। এই ধরনের সময় বাঁচানো রিটেল অপারেশন চালানোর ক্ষেত্রে অনেক বড় পার্থক্য তৈরি করে। রিটেইলারদের খুব ভালো লাগে যে তারা গ্রাহকদের অর্ডার একই দিনে সম্পন্ন করতে পারেন। দ্রুত প্রতিক্রিয়া সময় খুশি ক্রেতাদের পুনঃআগমনের দিকে পরিচালিত করে। যাঁরা উৎপাদনকারী প্রতিষ্ঠান এগিয়ে যেতে চান, তাঁদের কাছে ইনস্ট্যান্ট পিল পদ্ধতিতে রূপান্তর কেবল সময় বাঁচানোর ব্যাপার নয়। যখন উৎপাদন লাইনগুলো আরও মসৃণভাবে চলে এবং বিরতি কম হয়, তখন কোম্পানিগুলো কঠিন সময়সীমা মেটাতে সক্ষম হয় অনায়াসেই।

কেস স্টাডি: ব্যস্ত দোকানে 40% টার্নআরাউন্ড হ্রাস

চলুন দেখে নেওয়া যাক কী হয়েছিল যখন একটি স্থানীয় প্রিন্ট শপ ইনস্ট্যান্ট পিল ডিটিএফ প্রযুক্তি ব্যবহার শুরু করেছিল। সিস্টেমটি প্রয়োগের পর, তাদের চালানের সময় প্রায় 40% কমে গিয়েছিল। মালিকদের খুব খুশি ছিলেন কারণ তারা প্রতিদিন দ্বিগুণ কাজ করতে পারছিলেন এবং তবুও ক্রেতাদের খুশি রাখতে পারছিলেন। যা আসলে কাজ করেছিল তা হল নতুন প্রযুক্তির চারপাশে তাদের কাজের ধারা পুনর্গঠন করা। তারা এমনভাবে তাদের প্রিন্টিং সময়সূচি পরিবর্তন করেছিল যাতে কাজের মধ্যবর্তী সময়ে মেশিনগুলি আর আলসেমি করে না বসে থাকে। প্যাকেজিং থেকে কয়েকজন কর্মীকে প্রস্তুতির কাজে সরিয়ে আনা হয়েছিল যেখানে একটি বোতলের মুখে জমাট বাঁধা ছিল। গুণমানও আগের মতো ভালো ছিল, যা সবার জন্যই অবাক করে দিয়েছিল কারণ সাধারণত দ্রুততা কোথাও না কোথাও কিছু ক্ষতি করে। ছোট ব্যবসাগুলির জন্য যারা দৈনন্দিন কাজের মধ্যে আটকে আছেন, এটি দেখায় যে বুদ্ধিদায়ক প্রযুক্তিতে বিনিয়োগ কেবল সম্ভবই নয়, তা আসলে বড় ধরনের লাভজনক।

ব্যাচ প্রসেসিং-এর জন্য পাউডার অ্যাপ্লিকেশন স্বয়ংক্রিয়ভাবে করা

ডিটিএফ ফিল্মের প্রযুক্তিতে সাম্প্রতিক উন্নতি গুলি পাউডার প্রয়োগের প্রক্রিয়াটি স্বয়ংক্রিয় করার পথ তৈরি করেছে, যা আগে ডিটিএফ মুদ্রণের সময় সবচেয়ে বেশি সময় নেওয়া অংশ ছিল। এই পদক্ষেপটি স্বয়ংক্রিয় করা ব্যাচগুলি চালানোর সময় কার্যত সময় কমাতে সাহায্য করে এবং হাতে করা পদ্ধতির তুলনায় শ্রম খরচ কমিয়ে দেয়। যেসব দোকান পাউডার প্রয়োগের জন্য বিশেষভাবে তৈরি মেশিনে রূপান্তরিত হয়, তারা দেখতে পায় যে তারা দ্রুত পণ্যগুলি তৈরি করতে পারে এবং সমস্ত ব্যাচগুলিতে মান ধরে রাখতে পারে। সরঞ্জাম কেনার বিষয়টি নিয়ে ভাবলে দেখা যায় যে বর্তমানে বাজারে বেশ কয়েকটি মেশিন পাওয়া যায়। কোনটি সবচেয়ে ভালো কাজে লাগবে তা বেশিরভাগই নির্ভর করে প্রতি সপ্তাহে কতগুলি মুদ্রণ করা হবে এবং কতটা জায়গা পাওয়া যায় তার উপর। তবুও, যারা কার্যপ্রবাহ উন্নত করতে গুরুত্ব দেন তাদের অবশ্যই স্বয়ংক্রিয় পদ্ধতি বিবেচনা করা উচিত। সময়ের সাথে সাথে সঞ্চয় হয়, বিশেষ করে যখন মুদ্রণের পরিমাণ বাড়তে থাকে এবং বাজারে প্রতিযোগিতা তীব্র হয়ে ওঠে।

ইনস্ট্যান্ট পিল ডিটিএফ সমাধানের মানের সুবিধা

সকল টেক্সটাইল ধরনের জন্য স্পষ্ট ধার সংজ্ঞায়ন

DTF ইনস্ট্যান্ট ছাড়ানোর প্রযুক্তি সব ধরনের কাপড়ের উপর পরিষ্কার ধার সহ ছাপগুলি দেয়, যা দৃশ্যত অনেক ভালো দেখায়। যখন আমরা ছাড়ানোর সময় সেই অপেক্ষা করা সময়টা বাদ দিয়ে দিই, তখন যা ঘটে তা হলো তীক্ষ্ণ লাইন তৈরি হয়, যা পেশাদার চেহারা যুক্ত ছাপ তৈরির ক্ষেত্রে খুবই গুরুত্বপূর্ণ। এই DTF ফিল্মগুলি অনেক উপাদানের উপরেই ভালো কাজ করে। সূতি, পলিস্টার বা মিশ্রিত কাপড়ে এগুলি ব্যবহার করে দেখুন এবং লক্ষ্য করুন কীভাবে ক্ষুদ্রতম বিস্তারিত অংশগুলি তীক্ষ্ণ থাকে, যে কোনো ধরনের কাপড়ের উপরেই হোক না কেন। বস্ত্র নকশাকরণে যারা কাজ করেন, তারা বারবার বলেন যে ছাপের বিস্তারিত অংশগুলি পরিষ্কার রাখা খুবই গুরুত্বপূর্ণ, যদি কোনো ব্যবসায়িক প্রতিষ্ঠান তাদের উৎপাদন কাজে ভালো মান বজায় রাখতে চায়।

অন্ধকার এবং আলোকিত তক্তায় অবশিষ্ট পদার্থ কমানো

ইনস্ট্যান্ট পিল ডিটিএফ প্রযুক্তির একটি বড় সুবিধা হল এটি অবশিষ্ট স্যাঁতসেঁতে এবং কাপড়ে লেগে থাকা আঠালো জিনিসগুলি কমিয়ে দেয়, যেটি গাঢ় বা হালকা রঙের কাপড়ের ক্ষেত্রেই হোক না কেন। পুরানো প্রযুক্তিগুলি এই ধরনের অবশিষ্ট আঠালো সমস্যা থেকে মুক্তি পায় না, এবং এটি চূড়ান্ত পণ্যের চেহারা এবং ত্বকের সংস্পর্শে অনুভূতির উপর খারাপ প্রভাব ফেলে। যখন ইনস্ট্যান্ট পিলিংয়ের জন্য বিশেষভাবে তৈরি ডিটিএফ ফিল্মগুলি ব্যবহার করা হয়, তখন অধিকাংশ অসুবিধাজনক অবশিষ্ট সমস্যাগুলি চলে যায়, তাই ফলাফলগুলি অনেক পরিষ্কার দেখায় এবং রংগুলিও আরও উজ্জ্বল হয়ে ওঠে। শিল্প প্রতিবেদনগুলি ডিটিএফ-কে অবশিষ্ট পদার্থ রোধ করার ব্যাপারে ঐতিহ্যবাহী পদ্ধতির চেয়ে এগিয়ে রাখে, যা বিভিন্ন কাপড়ের বাজারে অনেক দোকানের মালিকদের তাদের মুদ্রণের প্রয়োজনে এই পদ্ধতিতে রূপান্তর করার কারণ হিসাবে দাঁড়ায়।

ধোয়ার পরীক্ষা ফলাফল: দৃঢ়তা তুলনা (২০২৪ ডেটা)

2024 এর মধ্যে ধোয়া পোশাকে পরীক্ষা করে দেখা গেছে যে DTF প্রযুক্তি দিয়ে তৈরি প্রিন্টগুলি পুরানো প্রিন্টিং পদ্ধতির তুলনায় কতটা টেকসই। এই পরীক্ষাগুলি যা খুঁজে পেয়েছে তা আশার চেয়ে বেশি ছিল - DTF প্রিন্টগুলি তাদের উজ্জ্বল রং বজায় রাখে এবং অনেকবার ধোয়ার পরেও ফেটে না বা রঙ না হারানোর মতো বিষয়গুলি দেখা যায়। কিছু সংখ্যামালা এটি সমর্থন করে, প্রায় 30 শতাংশ বেশি টেকসই হওয়ার প্রমাণ দেখা যায় যা আমরা পারম্পরিক পদ্ধতি থেকে পাই। শিল্প প্রতিবেদনগুলি এটিকে নিশ্চিত করে। যেসব কোম্পানি তাদের পণ্যগুলি দীর্ঘস্থায়ী এবং গ্রাহকদের জন্য আকর্ষক রাখতে চায়, এটি খুবই গুরুত্বপূর্ণ। দীর্ঘস্থায়ী প্রিন্ট মানে সন্তুষ্ট ক্রেতা যারা কেনার বিষয়ে আস্থা রাখেন, যা আজকাল বাজারে মূল্যের জন্য মূল্য চাওয়া মানুষের কাছে যৌক্তিক।

২০২৪-২০৩০ বাজার প্রবণতা ডিটিএফ গ্রহণের দিকে পরিচালিত করা

অনুমান করা হয়েছে ডিমান্ড ভিত্তিক ছাপানোতে ২৮% CAGR বৃদ্ধি

বাজার বিশ্লেষকদের মতে ২০২৪ থেকে ২০৩০ সালের মধ্যে অন-ডিমান্ড প্রিন্টিং খাতে প্রতি বছর প্রায় ২৮% হারে প্রবৃদ্ধি হতে পারে। আজকাল মানুষ ব্যক্তিগতভাবে তাদের পছন্দের পোশাক, ঘরবাড়ির সাজসজ্জা এবং ছোট ছোট উপহার দ্রব্যগুলির ক্ষেত্রে আকর্ষক চেহারার পণ্যের প্রতি বেশি আকৃষ্ট হচ্ছে। ডিরেক্ট টু ফিল্ম (ডিটিএফ) প্রিন্টিং প্রযুক্তি এই সব ক্ষেত্রেই ভালো কাজ করে কারণ এটি দীর্ঘস্থায়ী উজ্জ্বল রং প্রদান করে এবং জটিল ডিজাইনগুলি সহজে প্রিন্ট করা যায়। সবকিছুতে কাস্টমাইজেশনের প্রবণতা বাড়ার ফলে ডিটিএফ প্রিন্টারগুলি দোকান এবং কারখানাগুলিতে আরও বেশি পরিমাণে দেখা যাবে। এই প্রযুক্তি প্রারম্ভিক পর্যায়ে গ্রহণকারী ব্যবসাগুলি গ্রাহকদের কাস্টমাইজড পণ্যের চাহিদা বাড়ার সময় এগিয়ে থাকতে পারে।

পরিবেশ বান্ধব ফিল্ম উদ্ভাবন ব্যবহারিকতা চাহিদা মেটাতে

ডিটিএফ ফিল্ম প্রযুক্তিতে নতুন প্রযুক্তি আনতে গিয়ে সম্প্রতি আর্থিক স্থিতিশীলতার বিষয়টি খুব গুরুত্ব সহকারে নেওয়া হয়েছে। আমরা নানা ধরনের নতুন উপাদান ব্যবহার করে তৈরি পণ্য বাজারে আসতে দেখছি যা পুনর্ব্যবহার করা যায় এবং উৎপাদন প্রক্রিয়ায় ব্যবহৃত শক্তির পরিমাণ কমিয়ে দিচ্ছে। মানুষ এখন চায় পরিবেশ অনুকূল বিকল্প, এটা খুব সহজ আর স্পষ্ট। ক্রেতারা এমন পণ্য খুঁজছেন যার কারণে পৃথিবীর উপর প্রভাব কম পড়ে। বিশেষ করে প্রিন্টিং শপগুলি এখন আরও বেশি পরিবেশ অনুকূল বিকল্পের দিকে ঝুঁকছে। ডিটিএফ ফিল্মগুলিও আর আগের মতো স্থির নেই। এসব ফিল্ম তৈরি করা কোম্পানিগুলি জল খরচ এবং প্রয়োজনীয় রাসায়নিক দ্রব্যের পরিমাণ কমানোর পাশাপাশি মোট বর্জ্য উপাদানের পরিমাণও কমিয়েছে। স্মার্ট প্রস্তুতকারকরা ইতিমধ্যে তাদের নিয়মিত ডিটিএফ কার্যক্রমে পরিবেশ অনুকূল পদ্ধতিগুলি প্রয়োগ করতে শুরু করেছেন। মজার বিষয় হলো এটা শুধু পরিবেশের ক্ষতি রোধ করছে তাই নয়, বরং উৎপাদন প্রক্রিয়াটিকেও আরও ভালোভাবে চালাতে সাহায্য করছে। বর্তমান বাজারের দিকটি লক্ষ্য করলে স্পষ্টতই বোঝা যাচ্ছে যে আর্থিক স্থিতিশীলতা আর কোনো সাময়িক ফ্যাশন নয়, বরং এটি ব্যবসা পরিচালনার মৌলিক পদ্ধতিতে পরিবর্তন আনছে বিশ্বজুড়ে।

জগতব্যাপী ছোট ব্যাচের ব্যাখ্যানুযায়ী ব্যবস্থাপনার দিকে ঝুঁকি

ছোট পার্টির কাস্টমাইজড কাজের দিকে বাজারে প্রকৃত গতি আমরা লক্ষ্য করছি, যা স্থানীয় প্রিন্ট অপারেশনের জন্য কয়েকটি দুর্দান্ত সম্ভাবনা খুলে দিচ্ছে। ডিটিএফ ফিল্ম প্রযুক্তি কোয়ালিটি স্ট্যান্ডার্ডে কোনও আপস ছাড়াই এই ছোট রানের জন্য খুব ভালো কাজ করে। নমনীয়তা এবং দ্রুত কাজ করার বিষয়ে পুরানো পদ্ধতির তুলনায় এই পদ্ধতি নিজেকে ভালোভাবে পরিচালনা করে। মানুষ যে সংখ্যাগুলি নিয়ে কথা বলছে তা দেখুন - মানুষ তাদের জন্য তৈরি জিনিসগুলি চায়। এটিই হল কারণ যে কেন অনেক দোকানে ভিডিয়ো ফাইল সমাধানের সাথে যুক্ত হয়ে সেই বিশেষ আগ্রহী দলগুলিকে পরিবেশন করছে যারা ভর উৎপাদনের তুলনায় কিছু আলাদা চায়। যেসব প্রিন্ট দোকান এখন এই প্রবণতার সাথে যুক্ত হবে তাদের গ্রাহক বেস উল্লেখযোগ্যভাবে বাড়ানোর সম্ভাবনা রয়েছে এবং একক আইটেমের চাহিদা মেটানো হবে। এবং সত্যিই, কাস্টম প্রিন্টিংয়ের দুনিয়ায় ডিটিএফ-এর জন্য এই সম্পূর্ণ স্থানান্তরটি স্থায়ী হওয়ার মতো।

উৎপাদন লাইনে ইনস্ট্যান্ট পিল DTF বাস্তবায়ন

আইটি জি সজ্জায়নের জন্য পুনর্গঠন গাইড

অবিলম্বে পিল ডিটিএফ প্রযুক্তির সাথে কাজ করার জন্য বর্তমান গার্মেন্টে সরাসরি (ডিটিজি) প্রিন্টারগুলি পুনর্নির্মাণ করা উৎপাদনের সম্ভাবনার একটি সম্পূর্ণ নতুন দুনিয়া খুলে দেয়। প্রথমত, সরঞ্জামগুলির জন্য কোন পরিবর্তনের প্রয়োজন হবে তা বের করুন। বেশিরভাগ সেটআপের জন্য প্রিন্ট হেডগুলির সাথে কিছু সমন্বয় এবং সফটওয়্যার আপডেটের প্রয়োজন হবে। স্ক্রু ড্রাইভার, ক্যালিব্রেশন গিয়ারের মতো মৌলিক সরঞ্জামগুলির সাথে প্রস্তুত থাকুন এবং নিরাপদ অপারেশনের জন্য সর্বশেষ ফার্মওয়্যার আপডেটগুলি ভুলবেন না। অর্থও গুরুত্বপূর্ণ। আপফ্রন্ট খরচ বেশ বেশি হতে পারে, কিন্তু অনেক ব্যবসায়ী বিনিয়োগটি সময়ের সাথে প্রতিদান দিচ্ছে দেখেন। গত বছর যেমন তার সিস্টেম আপগ্রেড করেছিলেন সেই স্থানীয় দোকানদার মার্ককে নিন। তার ওয়ার্কফ্লো গতি 30% বেড়েছে এবং তিনি পোশাকের পাশাপাশি কাস্টম ফোন কেস অফার শুরু করেছেন, যা লাভ ব্যাপকভাবে বাড়িয়েছে। যত্নসহকারে বাজেট এবং উপযুক্ত সেটআপের মাধ্যমে, বেশিরভাগ ডিটিজি অপারেশন ডিটিএফ বাজার যে দিকে এগিয়ে যাচ্ছে সেখানে পাল্লা দিয়ে চলতে পারে।

কর্মচারী প্রশিক্ষণ প্রোটোকল দ্রুত গ্রহণের জন্য

ইনস্ট্যান্ট পিল ডিটিএফ প্রযুক্তি নিয়ে আসার সময় কর্মীদের উপযুক্ত প্রশিক্ষণ দেওয়াটাই সব কিছু বদলে দেয়। ভালো প্রশিক্ষণ প্রোগ্রামে প্রতিটি পদক্ষেপের বিস্তারিত নির্দেশাবলী, প্রত্যক্ষ অনুশীলনের সেশন এবং স্পষ্ট লিখিত ম্যানুয়াল অন্তর্ভুক্ত থাকা দরকার, যা পরবর্তীতে সবাই পর্যালোচনা করতে পারে। যখন কোম্পানিগুলো এই মৌলিক বিষয়গুলোতে মনোযোগ দেয়, তখন কর্মচারীরা প্রযুক্তিটি কীভাবে কাজ করে তা ভালোভাবে বুঝতে পারে, যার ফলে বাস্তবায়নের সময় সমস্যা কমে যায় এবং মোট উৎপাদনশীলতা বৃদ্ধি পায়। গত বছর এক্সওয়াইজেড ম্যানুফ্যাকচারিংয়ে যা হয়েছিল, তা-ই লক্ষ করুন, যখন তারা তাদের দলের জন্য উপযুক্ত প্রশিক্ষণ চালু করেছিল। কর্মীরা আশার চেয়েও দ্রুত বিষয়গুলো শিখে ফেলেছিল এবং নতুন সরঞ্জাম পরিচালনার ব্যাপারে অনেক বেশি আত্মবিশ্বাসী বোধ করছিল। এই আত্মবিশ্বাস পরবর্তীতে প্রকৃত ফলাফলে রূপান্তরিত হয়। কর্মচারীদের শিক্ষায় প্রাথমিক পর্যায়ে সময় বিনিয়োগ করা হলে সেটি সময়ের সাথে একাধিক ক্ষেত্রে লাভজনক প্রমাণিত হয়।

সাধারণ তাৎকালিক পিল চ্যালেঞ্জ সমস্যার পরিসমাপ্তি

অবিলম্বে ছাড় দেওয়ার জন্য DTF সমাধানগুলি প্রয়োগ করার সময় প্রায়শই মাথাব্যথা দেখা দেয়, যা সাধারণত সরঞ্জাম নষ্ট হয়ে যাওয়া বা আঠালো আঠা সংক্রান্ত সমস্যার সঙ্গে জড়িত। অধিকাংশ সংস্থাই নিয়মিত রক্ষণাবেক্ষণ পরীক্ষা করা এবং তাদের আঠার উপর পরীক্ষামূলক চালানোর মতো মৌলিক সমস্যা সমাধানের পদ্ধতির মাধ্যমে এই সমস্যার সমাধান করে থাকে। বছরের পর বছর ধরে এই ব্যবসায় থাকা মানুষদের সঙ্গে কথা বলাও খুব কার্যকর। এই অভিজ্ঞ অপারেটরদের অনেকেই আগে থেকেই একই ধরনের সমস্যার সম্মুখীন হয়েছেন এবং তারা বাস্তব পরিস্থিতিতে কার্যকর দ্রুত সমাধানের পরামর্শ দিতে পারেন। সমস্যাগুলি বেড়ে যাওয়ার আগেই সেগুলি ঠিক করে দেওয়া উৎপাদন প্রক্রিয়াটিকে মসৃণভাবে এগিয়ে নিয়ে যায় এবং পণ্যের সামঞ্জস্য বজায় রাখে। অবশ্যই, কেউ চাইবে না যে সময়ের অভাবে প্রস্তুতি প্রক্রিয়ায় অবিশ্বাস্য প্রযুক্তি গোটা প্রক্রিয়াটিকে বিশৃঙ্খল করে দিক।

সাধারণ জিজ্ঞাসা

DTF প্রিন্টিং কি?

ডিটিএফ (DTF), বা ফিল্মে সরাসরি প্রিন্টিং, একটি ডিজিটাল প্রিন্টিং প্রযুক্তি যেখানে ডিজাইন ফিল্মে প্রিন্ট করা হয় এবং তারপরে বিভিন্ন উপকরণে, বিশেষত টেক্সটাইলে, স্থানান্তরিত হয়।

সঙ্গত পিল বৈশিষ্ট্য প্রিন্টিং-এ কীভাবে উপকার করে?

অনুবাদযোগ্য পিল প্রযুক্তি শীতল হওয়ার প্রয়োজন ছাড়াই মুদ্রিত ডিজাইনটি সঙ্গে-সঙ্গে স্থানান্তর করতে দেয়, যা ঘূর্ণন সময় কমিয়ে উৎপাদনশীলতা বাড়ায়।

ডাবলিউ পিল ডিটিএফ থেকে মুদ্রাঙ্কনগুলো কি দurable?

হ্যাঁ, ধোয়ার পরীক্ষায় দেখা গেছে যে ইনস্ট্যান্ট পিল ডিটিএফ প্রযুক্তি ব্যবহার করে তৈরি মুদ্রাঙ্কনগুলো রঙের উজ্জ্বলতা এবং দurableতা বজায় রাখে, অনেক সময় ঐতিহ্যবাহী পদ্ধতিগুলোকে ছাড়িয়ে যায়।

ডিটিএফ মুদ্রণে কোন ধরনের রং ব্যবহৃত হয়?

ডিটিএফ মুদ্রণ মূলত জল-ভিত্তিক এবং পিগমেন্ট রং ব্যবহার করে, যেখানে প্রত্যেকটি উজ্জ্বলতা এবং ধোয়ার প্রতিরোধের বিষয়ে নির্দিষ্ট ফায়োডস প্রদান করে।

ডিটিএফ মুদ্রণ কি পরিবেশবান্ধব?

আগ্রহী আবিষ্কারগুলো ডিটিএফ ফিল্মকে পরিবেশবান্ধব করেছে পুনর্ব্যবহারযোগ্য উপাদান এবং শক্তি ব্যয় কমানোর জন্য জোর দিয়ে, যা ব্যবহারকারী স্থায়িত্ব প্রবণতা সঙ্গে মিলে যায়।