Understanding the Fundamental Differences Between PVC and PU Heat Transfer Materials

In the world of textile customization and garment decoration, choosing the right heat transfer material can make a significant difference in the quality and longevity of your finished products. PVC (Polyvinyl Chloride) heat transfer vinyl and PU (Polyurethane) film represent two of the most commonly used materials in the industry, each bringing its own set of characteristics and benefits to the table.

These materials serve as the foundation for creating vibrant, durable designs on various fabric types, from t-shirts and sportswear to promotional items and fashion accessories. Understanding their distinct properties is crucial for achieving optimal results in your textile printing projects.

Material Composition and Properties

Chemical Structure and Manufacturing Process

PVC heat transfer vinyl is produced through a complex manufacturing process that combines polyvinyl chloride with plasticizers and other additives. This composition results in a material that's notably thick and provides excellent coverage on garments. The manufacturing process involves creating multiple layers that work together to ensure proper adhesion and durability.

In contrast, PU film is made from polyurethane polymers, which naturally possess more flexibility and elasticity. The production process for PU film typically results in a thinner, more pliable material that maintains its softness even after repeated washing cycles. The molecular structure of PU allows for better integration with fabric fibers, creating a more natural feel.

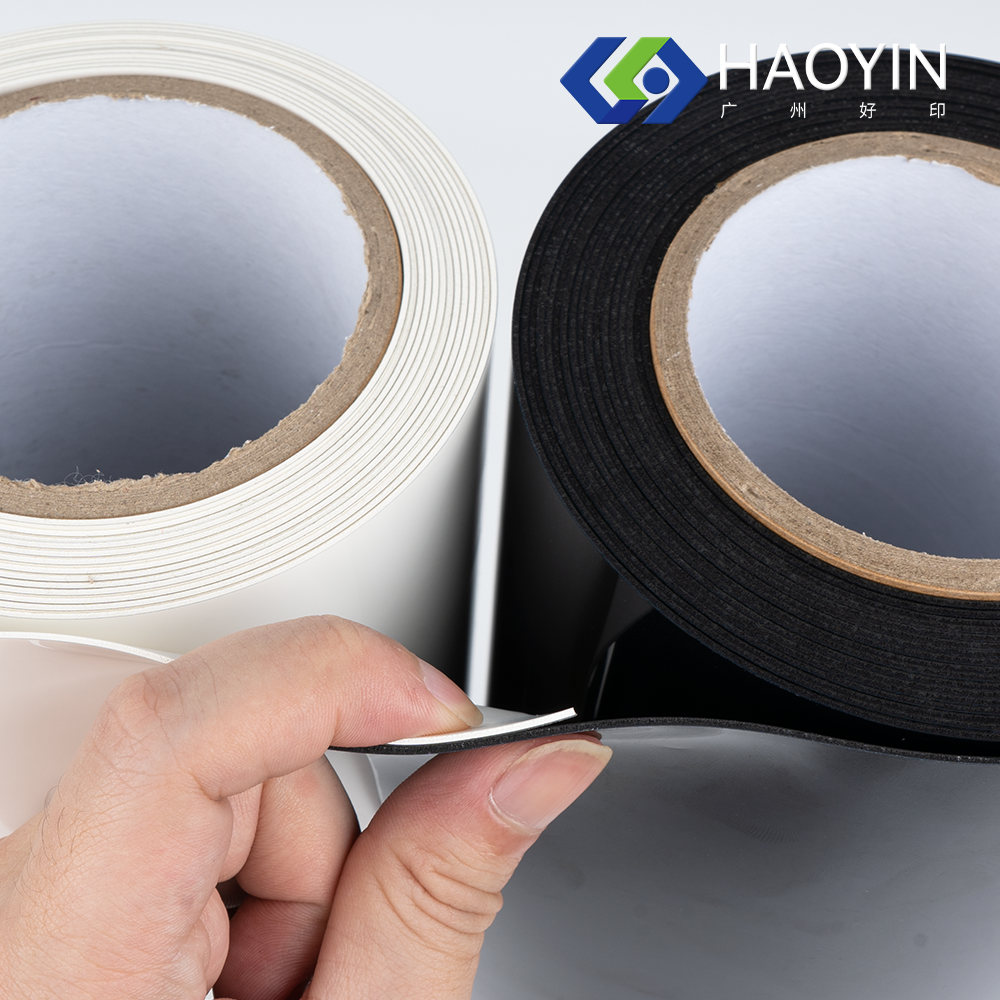

Physical Characteristics and Texture

PVC heat transfer vinyl typically exhibits a thicker, more structured feel with a distinctive glossy finish. The material has a robust nature that makes it particularly resistant to wear and tear, though this can sometimes result in a more rigid hand feel on the garment. The thickness of PVC can make it more suitable for certain applications where durability is the primary concern.

PU film, on the other hand, demonstrates remarkable softness and flexibility. Its thinner profile allows it to conform more naturally to the fabric's texture, creating a more integrated appearance. The material has a matte finish that many consider more premium and fashion-forward, making it particularly popular in high-end garment decoration.

Durability and Performance Analysis

Wash Resistance and Color Retention

When it comes to washability, both materials show impressive resilience, but their performance characteristics differ. PVC heat transfer vinyl maintains excellent color vibrancy even after numerous wash cycles, particularly in bold, solid designs. The material's thickness helps prevent color fading and ensures designs remain intact through regular laundering.

PU film demonstrates exceptional wash resistance while maintaining its soft hand feel. The material's ability to bond with fabric fibers at a molecular level contributes to its lasting durability. Colors remain vivid, and the material resists cracking or peeling, even when subjected to frequent washing and drying cycles.

Environmental Resistance and Longevity

PVC heat transfer vinyl shows remarkable resistance to environmental factors such as UV exposure and chemical contact. Its robust nature makes it particularly suitable for outdoor applications and garments that may be exposed to harsh conditions. The material maintains its structural integrity and appearance even under challenging circumstances.

While PU film may be slightly more susceptible to extreme environmental conditions, it compensates with superior flexibility and adaptability. The material's ability to move with the fabric helps prevent cracking and degradation over time, contributing to its overall longevity in normal use conditions.

Application Techniques and Best Practices

Temperature and Pressure Requirements

The application process for PVC heat transfer vinyl typically requires higher temperatures and firmer pressure settings. This ensures proper bonding between the material and the fabric substrate. Precise temperature control is essential, as PVC can become brittle if overheated or fail to adhere properly if underheated.

PU film generally requires lower application temperatures and moderate pressure settings. This gentler approach helps preserve the material's soft characteristics while ensuring secure adhesion. The more forgiving temperature range makes PU film easier to work with, particularly for those new to heat transfer applications.

Substrate Compatibility and Versatility

PVC heat transfer vinyl shows excellent compatibility with a wide range of fabric types, particularly cotton and polyester blends. The material's robust nature makes it suitable for sports uniforms, work wear, and other applications where durability is paramount. However, its thickness may limit its use on very lightweight or stretchy fabrics.

PU film exhibits superior versatility across different fabric types, including sensitive materials like nylon and spandex. Its thin profile and excellent stretch recovery make it ideal for performance wear and fashion applications. The material adapts well to both natural and synthetic fibers, offering expanded creative possibilities.

Cost Considerations and Value Analysis

Initial Investment and Material Costs

PVC heat transfer vinyl typically comes with a lower initial cost per square foot, making it an attractive option for large-scale production runs and budget-conscious projects. The material's durability often translates to good value over time, particularly in applications where longevity is essential.

While PU film generally commands a higher price point, its superior quality and performance characteristics often justify the investment. The material's excellent yield and minimal waste during production can help offset the higher initial cost, especially when considering the enhanced end-product quality.

Long-term Economic Benefits

When evaluating the long-term economic impact, PVC heat transfer vinyl's durability and resistance to wear can result in fewer customer returns and replacements. The material's stability in various conditions helps maintain consistent quality across production runs, reducing waste and rework costs.

PU film's premium quality and superior feel often command higher retail prices, potentially offering better profit margins despite higher material costs. The material's versatility and broad application range can also lead to expanded business opportunities and market reach.

Frequently Asked Questions

How do I determine which material is best for my specific project?

Consider factors such as the target garment type, intended use, and desired aesthetic finish. PVC heat transfer vinyl is ideal for durability-focused applications like sports uniforms and workwear, while PU film excels in fashion and performance wear where softness and flexibility are priorities.

Can both materials be used with the same heat press equipment?

Yes, both PVC heat transfer vinyl and PU film can be applied using standard heat press equipment, though they require different temperature and pressure settings. Always consult the manufacturer's specific guidelines for optimal application parameters.

What maintenance is required for garments decorated with these materials?

Both materials are machine washable, but it's recommended to wash garments inside out using cold or warm water. Avoid harsh chemicals and bleach. While both are dryer-safe, using lower heat settings can help extend the life of the applied designs.