Ewolucja dostosowywania: Instant-Peel Film DTF Występuje

Ograniczenia tradycyjnych metod transferu ciepła

Tradycyjne metody przenoszenia ciepła stosowane w druku tekstylnym napotykają poważne trudności przy realizacji skomplikowanych wzorów, co ogranicza zarówno swobodę twórczą, jak i jakość nadruku. Gdy pojawia się konieczność nanoszenia wielu warstw, efekty końcowe zaczynają się szybko pogarszać. Wyroby gotowe nie są również odporne na dłuższy czas użytkowania i z każdym użyciem tracą na wygląd. Na te problemy zwracała uwagę przez wiele lat Asocjacja Przemysłu Tekstylnego. Co gorsza, tradycyjne techniki wymagają dużo czasu na wykonanie, co spowalnia działanie linii produkcyjnych. Nie można także zbagatelizować ich wrażliwości na zmiany temperatury. Zakłady drukujące często muszą przeprowadzać kolejne testy, zanim osiągną satysfakcjonujące wyniki, marnując przy tym materiał, farbę i cenny czas. Wszystkie te problemy wskazują, że konieczne są lepsze rozwiązania, jeśli chcemy dalej rozwijać personalizowane tekstylia, które będą skutecznie spełniać potrzeby wszystkich zainteresowanych stron.

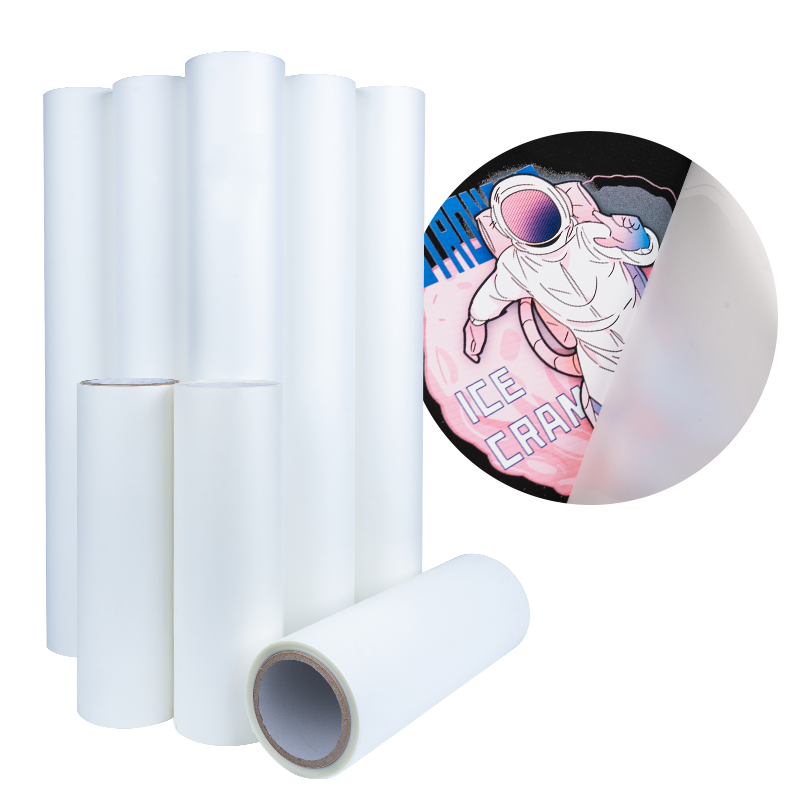

Rola filmu DTF w nowoczesnym drukowaniu na tkaninach

Technologia Direct-to-Film (DTF) odmieniła sposób drukowania na tekstyliach, pozwalając tworzyć szczegółowe wzory i gładkie przenoszenie obrazu na różne rodzaje tkanin. Tradycyjne metody po prostu nie są w stanie dorównać DTF, jeśli chodzi o skomplikowane grafiki. To właśnie dlatego DTF świetnie sprawdza się w wielu zastosowaniach – od odzieży sportowej, przez modne ubrania, po indywidualnie projektowane koszulki rozdawane przez firmy na wydarzeniach. Świat mody zdecydowanie zmierza w kierunku tej technologii, ponieważ klienci oczekują obecnie większego wyboru i kreatywnych rozwiązań. To, co naprawdę wyróżnia DTF, to fakt, że jego proces produkcyjny nie wymaga tak surowych ustawień temperatury. Oznacza to większą spójność produktu końcowego i mniejszą liczbę błędów w trakcie produkcji. Biorąc pod uwagę wszystkie te zalety, nie dziwi, że coraz więcej firm drukarskich przechodzi na technologię DTF przy realizacji projektów tekstylnych.

Dlaczego technologia Instant-Peel zmieniła reguły gry

Gdy producenci zaczęli integrować technologię natychmiastowego zrywania z foliami DTF, zauważyli praktyczne natychmiastowe ulepszenia w pracy. Największa różnica? Nie trzeba już czekać, aż arkusze transferowe ostygają, zanim je usunie się z wydrukowanych tkanin. W praktyce oznacza to mniej uszkodzonych projektów podczas aplikacji, dzięki czemu klienci widzą żywe kolory i szczegółowe wzory, za które zapłacili. Małe firmy i nowe przedsięwzięcia chętnie wybierają te folie, ponieważ mogą z nich korzystać osoby bez konieczności kilkutygodniowego szkolenia. Wystarczy wydrukować, poczekać minutę lub dwie, a następnie delikatnie usunąć folię podkładową. Dla firm dążących do zwiększenia produktywności przy jednoczesnym utrzymaniu wysokich standardów jakości, przejście na technologię natychmiastowego zrywania nie tylko jest korzystne, ale staje się koniecznością w dzisiejszym konkurencyjnym rynku, gdzie liczy się szybkość i precyzja.

Techniczna przewaga rozwiązań DTF z szybkim odrywaniem

Siła przylegania i trwałość prania

Filmy DTF o właściwościach natychmiastowego oddzielania doskonale przylegają do tkanin, dzięki czemu wytrzymują nawet wielokrotne prania. Dlatego świetnie sprawdzają się w przypadku codziennego noszonych ubrań. Institute of Fabric Care przeprowadziło badania, które wykazały, że te materiały wytrzymują wiele cykli prania bez utraty jakości. Testy laboratoryjne wykazały, że większość próbek zachowała integralność koloru po ponad 50 praniach, co jest lepsze niż wyniki osiągane przez standardowe transfery cieplne. To, co czyni DTF wyjątkowym, to sposób, w jaki mocno łączy się z powierzchnią tkaniny, ograniczając dokuczliwe przypadki, gdy nadruki zaczynają się łuszczyć lub pękać na krawędziach. Większość klientów twierdzi, że wydruki na ich produktach przez znacznie dłuższy czas prezentują się świeżo w porównaniu do innych metod, co zdecydowanie ma znaczenie, jeśli chodzi o stosunek jakości do ceny.

Jasność kolorów na różnych rodzajach tkanin

Duży plus rozwiązań DTF z natychmiastowym oddzielaniem folii tkwi w tym, jak żywe kolory wychodzą na różnych materiałach, niezależnie od tego, czy to zwykła bawełna, czy mieszanki z poliestru. Niektóre badania opublikowane w Dye & Color Science Journal sugerują, że te folie DTF rzeczywiście dają jaśniejsze kolory niż starsze techniki, być może nawet o około 30% lepsze w niektórych przypadkach. Różnica naprawdę ma znaczenie dla projektantów chcących eksperymentować z odważnymi kolorami, nie martwiąc się o przygaszone efekty. Kiedy ubrania po nadrukowaniu wyglądają bardziej kolorowo i efektownie, klienci zauważają to i doceniają jakość. Obecnie ludzie chcą, by ich odzież wizualnie wyróżniała się na tle innych, dlatego tego rodzaju technologia pomaga producentom nadążać za oczekiwaniami zakupowymi klientów w kwestii wyrobów odzieżowych.

Efektywność operacyjna w produkcji o dużym objęciu

W miarę jak coraz więcej firm sięga po rozwiązania drukowania na żądanie, technologia DTF z funkcją natychmiastowego odrywania pomaga im rozwijać działalność, nie rezygnując przy tym z jakości druku. Badania przeprowadzone na podstawie różnych raportów branżowych wskazują, że zastosowanie tych technik DTF często prowadzi do wzrostu produkcji rzędu 40 procent, co ma ogromne znaczenie dla producentów realizujących duże zlecenia i walczących o utrzymanie tempa z rywalami. To, co wyróżnia tę technologię, to wysoki stopień automatyzacji procesu natychmiastowego odrywania. Przekłada się to na niższe koszty personelu, ponieważ praca ręczna jest ograniczona, a mimo to osiągane są założone wskaźniki produkcji. Dla firm średnich i małych, które chcą obniżać koszty, a jednocześnie osiągać dobre wyniki, taki sposób organizacji staje się bardzo atrakcyjny w konkurencyjnych rynkach, na których wszyscy robią to samo.

Skalowalna produkcja bez kompromisów w kwestii jakości

Od pojedynczego zamówienia do elastyczności druku masowego

Technologia DTF z natychmiastowym odpięciem oferuje bezprecedensową elastyczność przy przechodzeniu od pojedynczych zamówień do druku masowego. Ta elastyczność jest wspierana przez krótkie czasy zmiany, co znacząco redukuje simplyfikację między seriami produkcyjnymi. Taka elastyczność jest kluczowa dla spełnienia różnorodnych wymagań klientów, zapewniając szybkie realizację zamówień bez kompromitowania jakości.

Integracja z automatycznymi przepływami pracy

Gdy rozwiązania DTF z błyskawicznym oddzielaniem folii łączy się z zautomatyzowanymi przepływami pracy, cały proces drukowania staje się znacznie sprawniejszy i szybszy. Takie zautomatyzowane systemy przejmują zadania związane z transportem materiałów, które wcześniej wymagały dużej pracy ręcznej, co zmniejsza frustrujące błędy popełniane przez ludzi, gdy są zmęczeni lub naciskani czasem. Prawdziwą zaletą jest łatwość wkomponowania tych nowych systemów w istniejące linie produkcyjne bez konieczności przekształcania wszystkiego od podstaw. Większość producentów stwierdza, że wystarczy jedynie drobne dostrojenie kilku elementów, aby szybko powrócić do pełnej wydajności. I trzeba przyznać, że nikt nie chce, by cała działalność zatrzymywała się na czas modernizacji.

Kosztowna tranzycja dla rozwijających się operacji

Dla firm chcących rozwijać się bez nadmiernego obciążania budżetu, technologia DTF o szybkiej separacji stanowi mądre inwestycje w rozszerzaniu usług. W przeciwieństwie do niektórych wysokiej klasy systemów drukujących, które wymagają dużych nakładów początkowych, DTF wyróżnia się tym, że nie wymaga tak dużego zaangażowania finansowego od samego początku. Małe firmy mogą znacznie łatwiej wejść na ten rynek niż było to możliwe z tradycyjnymi metodami. Z biegiem czasu firmy zauważają realne oszczędności finansowe wynikające z mniejszego marnotrawstwa materiałów i szybszych serii producyjnych. Wiele zakładów drukarskich informuje o zmniejszeniu liczby błędów i konieczności powtarzania wydruków po przejściu na technologię DTF, co w ciągu miesięcy daje znaczące efekty. Dlatego tak wiele rozwijających się przedsiębiorstw decyduje się na tę technologię jako swoje główne rozwiązanie do poszerzania możliwości przy jednoczesnym kontrolowaniu kosztów.

Wybór odpowiedniego filmu DTF dla Twoich potrzeb

Porównanie wydajności między gorącym, zimnym a natychmiastowym odrywaniem

Różnice między filmami DTF typu gorącego, zimnego i natychmiastowego usunięcia naprawdę rzucają się w oczy przy pracach drukarskich. Zgodnie z najnowszym raportem Printing Today, do nakładania filmów typu gorącego usunięcie wymagane jest bardzo dokładne zgranie czasowe. Najlepiej sprawdzają się one w rękach doświadczonych użytkowników, którzy dokładnie wiedzą, kiedy należy je obsługiwać, aby niczego nie zepsuć. Wersje typu zimnego usunięcia wspomagają druk wielowarstwowy, jednak wiążą się z własnymi problemami, ponieważ wymagają czasu na ostygnięcie po wydrukowaniu, co naturalnie znacznie zwalnia cały proces. Opcje typu natychmiastowego usunięcia, takie jak FOREVER DTF Premium Matt, eliminują tę zmienność. Drukarnie mogą od razu przejąć te filmy tuż po ich przygotowaniu na materiale, bez konieczności oczekiwania. Oznacza to szybsze czasy realizacji i lepsze rezultaty za każdym razem, nawet jeśli obsługę sprzętu wykonuje osoba niedoświadczona.

Uwagi dotyczące zgodności tkanin

Uzyskanie odpowiedniej folii DTF oznacza zwrócenie szczególnej uwagi na jej działanie z różnymi tkaninami, aby uniknąć problemów takich jak wycieranie kolorów czy odpadanie nadruków. Wielokrotnie zauważaliśmy, że mieszanki poliestrowe stosowane powszechnie w odzieży doskonale współpracują z foliami DTF do natychmiastowego zrywania. Dobrą wiadomością jest to, że te folie przylegają poprawnie i zachowują swoje żywe kolory nawet po wielu praniach, co z pewnością zauważają i doceniają klienci. Poświęcenie czasu na dopasowanie folii do tkanin nie ma jedynie na celu poprawę wyglądu. W rzeczywistości wydłuża to trwałość wyrobów z nadrukami i daje firmom więcej możliwości przy tworzeniu indywidualnych projektów, które ludzie chcą nosić.

Czynniki ekologiczne przy wyborze filmu

Coraz więcej osób interesuje się zrównoważoną produkcją, dlatego wybór ekologicznych folii DTF stał się bardzo ważny dla firm. Ostatni raport opublikowany przez Eco Textile News wskazuje, że nowe osiągnięcia w technologii DTF oferują obecnie bardziej przyjazne dla środowiska alternatywy w postaci ekologicznych tuszy i folii, które zmniejszają oddziaływanie na środowisko. Przedsiębiorstwa, które przechodzą na takie materiały, zyskują dwie główne korzyści. Po pierwsze, są lepiej przygotowane do zaspokojenia obecnych oczekiwań klientów, ponieważ zrównoważony rozwój ma duże znaczenie dla wielu nabywców. Po drugie, stosowanie produktów przyjaznych środowisku pomaga w budowaniu lepszej reputacji marki, ponieważ pokazuje autentyczne zaangażowanie w kwestie ekologiczne. Wybór zrównoważonych folii umożliwia spełnienie wymogów środowiskowych oraz przyciągnięcie świadomych konsumentów, którzy preferują marki dzielące ich wartości, co na dłuższą metę prowadzi do budowy silniejszych relacji z klientami.

Ochrona przyszłości dzięki natychmiastowej technologii DTF z odrywaniem

Nowe zastosowania poza odzieżą

Technologia DTF o natychmiastowym oddzielaniu nie ogranicza się już tylko do odzieży. Wszędzie zaczynamy ją dostrzegać, zwłaszcza w artykułach takich jak pościel, ręczniki, a nawet w drobnych prezentach rozdawanych na targach. Co czyni te materiały tak wyjątkowymi? Otóż pozwalają na realizację niezwykle szczegółowych wzorów, które wcześniej były po prostu niemożliwe. Coraz częściej stosuje się ją również do obudów na telefony, dekoracji ścian i nieskończonej liczby innych ozdobnych przedmiotów. Prawdziwym atutem okazuje się ogromna uniwersalność tych folii DTF. Dla firm gotowych do myślenia poza schematami, otwierają się nowe rynki pełne możliwości. Firma, które szybko skorzystają z tej technologii, mogą poszerzyć swoją ofertę i wyprzedzać konkurencję tkwiącą jeszcze w przeszłości.

Innowacje w z zakresu trwałych tuszów i filmów

Trwałe tusze i folie do druku DTF (Direct to Film) stały się nieodzowne, ponieważ coraz więcej osób poszukuje przyjaznych środowisku opcji. Zakłady drukarskie na całym kraju przechodzą na materiały biodegradowalne i tusze na bazie wody, ponieważ zmniejszają one zanieczyszczenie środowiska, a jednocześnie zapewniają dobre rezultaty na tkaninach. Niektóre z tych ekologicznych alternatyw posiadają faktycznie oficjalne certyfikaty ekologiczne od uznanych organizacji, co wyróżnia je na półkach sklepowych i z czasem buduje zaufanie klientów. Firmy, które przyjmują takie praktyki, lepiej odnajdują się na dzisiejszym rynku, gdzie dla nabywców istotna jest zrównoważoność. Wiele firm raportuje poprawę sprzedaży po dokonaniu przejścia, a także możliwość opowiedzenia historii świadczącej o trosce o planetę, bez kompromitowania jakości druków dla klientów.

Wzmocnienia przepływów pracy napędzane sztuczną inteligencją

Dodanie sztucznej inteligencji do procesów druku DTF naprawdę zmieniło sposób, w jaki te operacje są realizowane. Patrząc na to, co dzieje się w branży w tej chwili, wiele firm zauważa, że ich systemy potrafią wykrywać potencjalne opóźnienia zanim się one pojawią. Jedno z badań wspomnianych w Technology Review sugeruje, że tego rodzaju możliwości predykcyjne mogą rzeczywiście skrócić marnowany czas o około 20%. Kiedy firmy zaczynają korzystać z inteligentnych narzędzi analitycznych opartych na sztucznej inteligencji, uzyskują lepszą kontrolę nad momentem zużycia materiałów oraz planowaniem linii produkcyjnych. Prawdziwą zaletą jest jednak coś więcej niż tylko oszczędność pieniędzy. Przedsiębiorstwa, które wdrażają takie technologie, zauważają, że potrafią szybciej reagować na żądania klientów, jednocześnie kontrolując koszty. To właśnie daje im realną przewagę nad konkurentami, którzy nie zainwestowali jeszcze w podobny sposób w swoje możliwości druku DTF.

Najczęściej zadawane pytania

Jaka są główne zalety natychmiastowego filmu DTF do odrywania?

Filmy DTF do natychmiastowego odrywania oferują wysoką moc przylegania, trwałość podczas mycia, jasność barw na różnych rodzajach tkanin, efektywność operacyjną oraz skalowalne możliwości produkcyjne. Są one odpowiednie dla codziennej odzieży i pomagają biznesom skutecznie odpowiadać na różnorodne wymagania klientów.

Jak technologia szybkiego odrywania poprawia proces personalizacji?

Technologia szybkiego odrywania skraca czasy oczekiwania między drukowaniem a aplikacją, zmniejsza ryzyko zniekształcenia projektu i ułatwia użytkowanie, zwłaszcza dla małych firm i startupów.

Czy filmy DTF z technologią szybkiego odrywania są przyjazne środowisku?

Tak, postępy w technologii DTF doprowadziły do bardziej zrównoważonych opcji tuszu i filmów, w tym tuszy biodegradowalnych i na wodzie, wspierając wysiłki ochrony środowiska i spełniając obecne trendy rynkowe, które prioritize ekologiczność.

Jak filmy DTF z technologią szybkiego odrywania porównują się do filmów z odrywaniem gorącym i zimnym?

Filmy z szybkim odrywaniem pozwalają na natychmiastowe obsługiwanie po druku, zwiększając efektywność przepływu pracy i zapewniając spójną jakość bez konieczności długiego chłodzenia jak w przypadku odrywania zimnego lub dokładnego czasowania jak w przypadku odrywania gorącego.

Spis treści

- Ewolucja dostosowywania: Instant-Peel Film DTF Występuje

- Techniczna przewaga rozwiązań DTF z szybkim odrywaniem

- Skalowalna produkcja bez kompromisów w kwestii jakości

- Wybór odpowiedniego filmu DTF dla Twoich potrzeb

- Ochrona przyszłości dzięki natychmiastowej technologii DTF z odrywaniem

-

Najczęściej zadawane pytania

- Jaka są główne zalety natychmiastowego filmu DTF do odrywania?

- Jak technologia szybkiego odrywania poprawia proces personalizacji?

- Czy filmy DTF z technologią szybkiego odrywania są przyjazne środowisku?

- Jak filmy DTF z technologią szybkiego odrywania porównują się do filmów z odrywaniem gorącym i zimnym?