การพัฒนาของการปรับแต่ง: Instant-Peel ฟิล์มดีทีเอฟ เกิดขึ้น

ข้อจำกัดของวิธีการถ่ายโอนความร้อนแบบเดิม

วิธีการถ่ายเทความร้อนแบบดั้งเดิมสำหรับการพิมพ์ผ้าใบเจอกับปัญหาที่เกิดขึ้นจริงเมื่อต้องจัดการกับลวดลายที่มีความซับซ้อน ซึ่งแทบจะทำให้ทั้งความคิดสร้างสรรค์และคุณภาพของการพิมพ์ลดลง เมื่อมีการใช้หลายเลเยอร์เข้าด้วยกัน สิ่งต่างๆ ก็เริ่มผิดพลาดขึ้นอย่างรวดเร็ว สินค้าที่ผลิตออกมาย่อมไม่ทนทานตามกาลเวลา และดูทรุดโทรมลงไปด้วย นี่คือสิ่งที่สมาคมอุตสาหกรรมสิ่งทอมานชี้ให้เห็นเป็นเวลานานหลายปีแล้ว ยิ่งไปกว่านั้น เทคนิคแบบดั้งเดิมยังใช้เวลานานมากในการดำเนินการ ทำให้สายการผลิตทั้งหมดชะลอตัวลงไปด้วย และอย่าลืมถึงความไวต่ออุณหภูมิของมัน พิมพ์ช็อปต้องทดสอบซ้ำแล้วซ้ำอีกก่อนจะได้ผลงานที่ออกมาดี ทำให้เสียผ้า เสียหมึกพิมพ์ และเสียเวลาอันมีค่าไปกับกระบวนการเหล่านี้ ปัญหาทั้งหมดที่กล่าวมานี้แสดงให้เห็นว่าเราต้องการทางแก้ไขที่ดีกว่า หากยังอยากก้าวต่อไปในอุตสาหกรรมผ้าใบสั่งทำพิเศษที่ใช้งานได้จริงสำหรับทุกฝ่ายที่เกี่ยวข้อง

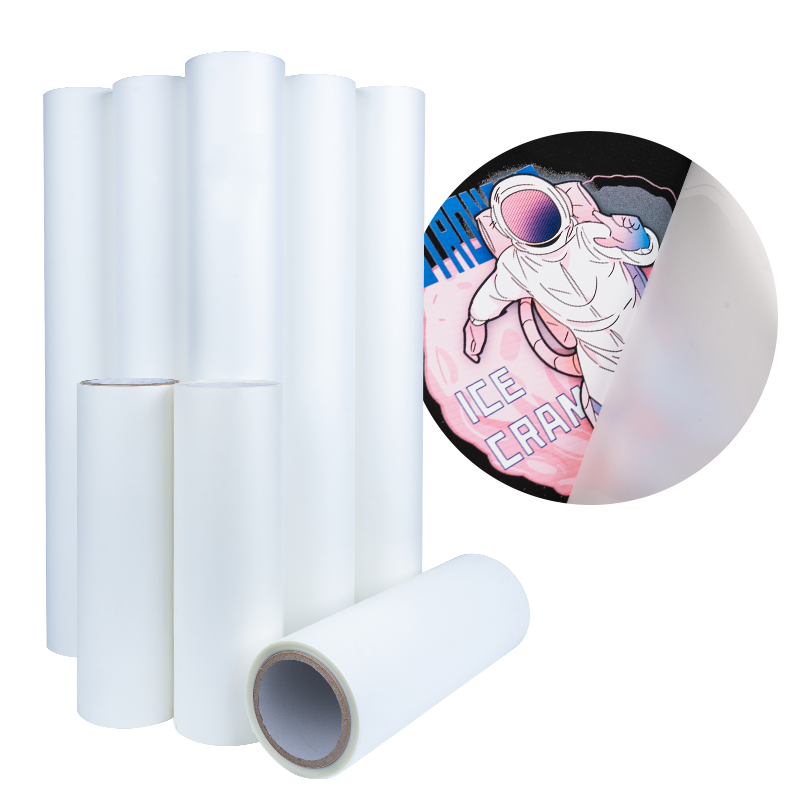

บทบาทของฟิล์ม DTF ในการพิมพ์ผ้าสมัยใหม่

เทคโนโลยี Direct-to-Film (DTF) ได้เปลี่ยนวิธีการพิมพ์ลวดลายบนผ้าใบให้เราสามารถสร้างลวดลายที่ละเอียดอ่อนและการถ่ายเทที่เนียนเรียบบนผ้าหลากหลายชนิด ในขณะที่วิธีการแบบดั้งเดิมไม่สามารถทำได้เท่ากับ DTF เมื่อเป็นงานออกแบบที่ซับซ้อน ซึ่งทำให้ DTF เหมาะสำหรับใช้งานหลากหลายประเภท ตั้งแต่เสื้อผ้าออกกำลังกาย เสื้อผ้าแฟชั่นแนวโน้มใหม่ไปจนถึงเสื้อยืดที่บริษัทสั่งทำพิเศษแจกในงานอีเวนต์ต่าง ๆ วงการแฟชั่นกำลังมุ่งหน้าไปในทิศทางนี้อย่างชัดเจน เพราะปัจจุบันลูกค้าต้องการทางเลือกที่หลากหลายและรูปลักษณ์ที่สร้างสรรค์มากยิ่งขึ้น สิ่งที่ทำให้ DTF โดดเด่นคือกระบวนการทำงานที่ไม่ต้องควบคุมอุณหภูมิอย่างเคร่งครัดเหมือนเทคโนโลยีอื่น ๆ ซึ่งช่วยให้ผลิตภัณฑ์สุดท้ายมีความสม่ำเสมอสูงขึ้น และลดข้อผิดพลาดระหว่างกระบวนการผลิต เมื่อรวมข้อดีทั้งหมดเหล่านี้เข้าด้วยกัน จึงไม่น่าแปลกใจที่ปัจจุบันมีโรงพิมพ์จำนวนมากหันมาใช้ DTF ในการผลิตงานพิมพ์บนผ้าใบมากขึ้น

เหตุใดเทคโนโลยี Instant-Peel จึงเปลี่ยนเกม

เมื่อผู้ผลิตเริ่มนำเทคโนโลยีการลอกออกทันที (instant peel) มาใช้กับฟิล์ม DTF ของตน พวกเขาสังเกตเห็นว่ากระบวนการทำงานดีขึ้นแทบจะทันที ความแตกต่างที่เห็นได้ชัดเจนที่สุดคือ ไม่ต้องรอให้แผ่นถ่ายโอนเย็นลงก่อนลอกออกจากการพิมพ์บนผ้าอีกต่อไป สิ่งที่เกิดขึ้นจริงคือ ลดการออกแบบที่บิดเบือนหรือเสียหายระหว่างการใช้งาน ทำให้ลูกค้าได้เห็นสีสันที่สดใสและรายละเอียดที่ประณีตตามที่จ่ายเงินไป ร้านค้าขนาดเล็กและธุรกิจใหม่ต่างชื่นชอบฟิล์มเหล่านี้ เพราะทุกคนสามารถใช้งานได้โดยไม่ต้องฝึกฝนเป็นเวลานานหลายสัปดาห์ เพียงแค่พิมพ์ รอหนึ่งหรือสองนาที จากนั้นค่อยๆ ดึงแผ่นฟิล์มด้านหลังออกเบาๆ เท่านั้น สำหรับบริษัทที่ต้องการเพิ่มประสิทธิภาพในการทำงานโดยยังคงมาตรฐานคุณภาพไว้สูง การเปลี่ยนมาใช้เทคโนโลยีลอกออกทันทีไม่ใช่เพียงแค่มีประโยชน์ แต่กำลังกลายเป็นสิ่งจำเป็นในตลาดที่มีการแข่งขันสูงในปัจจุบัน ซึ่งความเร็วและความแม่นยำมีบทบาทสำคัญที่สุด

ความเหนือกว่าทางเทคนิคของโซลูชัน DTF แบบลอกออกทันที

ความแข็งแรงของการยึดเกาะและความทนทานต่อการซัก

ฟิล์ม DTF ที่มีคุณสมบัติลอกออกได้ทันทีสามารถยึดติดกับผ้าได้ดีเยี่ยม จึงทนทานแม้จะผ่านการซักมาหลายครั้ง ด้วยเหตุนี้จึงเหมาะสำหรับใช้กับเสื้อผ้าทั่วไปที่สวมใส่เป็นประจำ สถาบันดูแลรักษาผ้า (Fabric Care Institute) ได้ทำการวิจัยและพบว่าวัสดุชนิดนี้สามารถทนต่อการซักในเครื่องได้หลายรอบโดยไม่เสื่อมสภาพ ผลการทดสอบในห้องทดลองพบว่าตัวอย่างส่วนใหญ่ยังคงสีสันสมบูรณ์แม้ผ่านการซักไปแล้วมากกว่า 50 ครั้ง ซึ่งดีกว่าผลลัพธ์ที่การถ่ายเทความร้อนแบบทั่วไปสามารถทำได้ สิ่งที่ทำให้ DTF มีความพิเศษคือการยึดติดกับเนื้อผ้าอย่างแน่นหนา ช่วยลดปัญหาที่รบกวนใจอย่างการลอกหรือแตกร้าวตามขอบของลวดลายที่พิมพ์ ลูกค้าส่วนใหญ่รายงานว่าสินค้าที่พิมพ์ลายด้วยวิธีนี้ยังคงดูใหม่อยู่เสมอเป็นเวลานาน เมื่อเทียบกับวิธีการอื่น ๆ ซึ่งแน่นอนว่ามีความสำคัญอย่างมากเมื่อพูดถึงเรื่องคุ้มค่ากับการลงทุน

ความสดใสของสีบนประเภทเนื้อผ้าต่างๆ

ข้อได้เปรียบที่สำคัญของโซลูชัน DTF ที่ลอกทันทีคือสีสันที่สดใสที่ได้ไม่ว่าจะเป็นผ้าฝ้ายธรรมดาหรือวัสดุผสมโพลีเอสเตอร์ งานวิจัยบางส่วนในวารสาร Dye & Color Science ชี้ให้เห็นว่าฟิล์ม DTF เหล่านี้สามารถให้สีสันที่สว่างกว่าวิธีการเก่าๆ อาจสูงกว่าถึง 30% ในบางกรณี ความแตกต่างนี้มีความสำคัญอย่างมากสำหรับนักออกแบบที่ต้องการทดลองใช้สีสันที่เข้มข้นโดยไม่ต้องกังวลว่าผลงานจะออกมาจืดชืด เมื่อเสื้อผ้าหลังพิมพ์ลายออกมาดูมีสีสันและสะดุดตามากขึ้น ลูกค้าก็มักจะสังเกตเห็นและชื่นชมในคุณภาพ ผู้คนในปัจจุบันต่างต้องการเสื้อผ้าที่โดดเด่นในเชิงภาพ ดังนั้นเทคโนโลยีประเภทนี้จึงช่วยให้ผู้ผลิตสามารถตอบสนองความต้องการของผู้บริโภคในด้านสินค้าแฟชั่นได้ดียิ่งขึ้น

ประสิทธิภาพในการดำเนินงานสำหรับการผลิตจำนวนมาก

เมื่อองค์กรต่างๆ หันมาใช้โซลูชันการพิมพ์แบบออนดีมานด์มากขึ้น เทคโนโลยี DTF แบบ instant peel ก็ช่วยให้พวกเขาสามารถขยายการดำเนินงานได้โดยไม่ต้องแลกกับคุณภาพของการพิมพ์ รายงานวิจัยจากหลายอุตสาหกรรมระบุว่า เทคนิค DTF มักจะช่วยเพิ่มกำลังการผลิตได้ราว 40 เปอร์เซ็นต์ ซึ่งเป็นเรื่องสำคัญมากสำหรับผู้ผลิตที่ต้องรับมือกับคำสั่งซื้อขนาดใหญ่ และต้องแข่งขันกับตลาด สิ่งที่ทำให้เทคโนโลยีนี้โดดเด่นคือ กระบวนการ instant peel ที่มีความเป็นอัตโนมัติสูง ซึ่งช่วยลดค่าใช้จ่ายด้านแรงงาน เนื่องจากมีการทำงานที่ต้องทำด้วยมือน้อยลง แต่ยังคงประสิทธิภาพการผลิตตามเป้าหมายไว้ได้ สำหรับธุรกิจขนาดเล็กถึงขนาดกลางที่ต้องการลดต้นทุน แต่ยังคงคุณภาพของผลงาน ระบบนี้จึงน่าสนใจอย่างมาก เมื่อพวกเขาต้องแข่งขันในตลาดที่ผู้เล่นรายอื่นๆ ต่างทำสิ่งเดียวกัน

การผลิตที่ปรับขนาดได้โดยไม่กระทบต่อคุณภาพ

จากออร์เดอร์เดี่ยวถึงความยืดหยุ่นในการพิมพ์จำนวนมาก

เทคโนโลยี DTF ลอกออกทันทีมอบความยืดหยุ่นที่ไม่มีใครเทียบได้ในการเปลี่ยนจากการสั่งซื้อเดี่ยวไปจนถึงการพิมพ์จำนวนมาก ความยืดหยุ่นนี้ได้รับการสนับสนุนจากเวลาเปลี่ยนแปลงที่รวดเร็ว ลดเวลาหยุดทำงานระหว่างรอบการผลิตอย่างมาก ความยืดหยุ่นเช่นนี้มีความสำคัญสำหรับการตอบสนองความต้องการของลูกค้าที่หลากหลาย ช่วยให้มั่นใจได้ว่าการส่งมอบคำสั่งซื้ออย่างรวดเร็วโดยไม่กระทบต่อคุณภาพ

การผสานรวมกับกระบวนการทำงานอัตโนมัติ

เมื่อโซลูชัน DTF แบบพีลทันทีถูกจับคู่เข้ากับกระบวนการทำงานอัตโนมัติ กระบวนการพิมพ์ทั้งหมดจะดำเนินไปอย่างราบรื่นและรวดเร็วมากยิ่งขึ้น ระบบที่ทำงานอัตโนมัติเหล่านี้จะจัดการงานที่เกี่ยวข้องกับการเคลื่อนย้ายวัสดุ ซึ่งเป็นงานที่เคยต้องใช้แรงงานคนจำนวนมาก ช่วยลดข้อผิดพลาดที่น่าหงุดหงิดซึ่งมักเกิดขึ้นเมื่อพนักงานเหนื่อยล้าหรือเร่งรีบ ข้อได้เปรียบจริงๆ อยู่ที่ความง่ายดายในการนำระบบใหม่เหล่านี้มาผนวกรวมเข้ากับสายการผลิตเดิม โดยไม่จำเป็นต้องรื้อทั้งระบบออกทั้งหมด ผู้ผลิตส่วนใหญ่พบว่าพวกเขาต้องปรับเปลี่ยนเพียงเล็กน้อยเท่านั้น ก่อนที่จะกลับมาดำเนินการผลิตได้เต็มประสิทธิภาพอีกครั้ง และพูดตามจริงแล้ว ไม่มีใครต้องการให้การดำเนินงานทั้งหมดต้องหยุดชะงักลงขณะที่มีการอัปเกรดระบบหรอก

การเปลี่ยนผ่านที่คุ้มค่าสำหรับธุรกิจที่เติบโต

สำหรับบริษัทที่ต้องการเติบโตโดยไม่ต้องใช้เงินจำนวนมาก นวัตกรรม DTF แบบ instant peel ถือเป็นการลงทุนที่ชาญฉลาดเมื่อขยายบริการ เทียบกับระบบพิมพ์ระดับสูงบางประเภทที่ต้องใช้เงินลงทุนครั้งแรกจำนวนมาก DTF มีความโดดเด่นตรงที่ไม่ต้องการเงินทุนก้อนโตในช่วงเริ่มต้น ร้านค้าขนาดเล็กสามารถเริ่มใช้งานเทคโนโลยีนี้ได้ง่ายกว่าวิธีการแบบดั้งเดิมมาก ระยะยาว บริษัทต่าง ๆ จะเห็นการประหยัดค่าใช้จ่ายจริงจากวัสดุที่เสียหายน้อยลงและการผลิตที่รวดเร็วขึ้น ร้านพิมพ์หลายแห่งรายงานว่าลดข้อผิดพลาดและการพิมพ์ซ้ำได้หลังเปลี่ยนมาใช้ DTF ซึ่งช่วยประหยัดค่าใช้จ่ายได้อย่างต่อเนื่องทุกเดือน นี่จึงเป็นเหตุผลว่าทำไมธุรกิจที่กำลังเติบโตจำนวนมากจึงหันมาใช้เทคโนโลยีนี้เป็นทางเลือกหลักในการเพิ่มศักยภาพการผลิตในขณะที่ยังควบคุมค่าใช้จ่ายได้

การเลือกฟิล์ม DTF ที่เหมาะสมสำหรับความต้องการของคุณ

การเปรียบเทียบสมรรถนะระหว่าง Hot vs Cold vs Instant Peel

ข้อแตกต่างระหว่างฟิล์ม DTF แบบรีดร้อน รีดเย็น และรีดทันทีนั้นเห็นได้ชัดเจนเมื่อเข้าสู่ขั้นตอนการพิมพ์จริง โดยฟิล์มแบบรีดร้อนต้องการจังหวะเวลาที่แม่นยำในการใช้งานตามที่นิตยสาร Printing Today รายงานล่าสุด ฟิล์มประเภทนี้มักเหมาะกับผู้ที่มีประสบการณ์ซึ่งรู้ว่าเมื่อไรควรจัดการฟิล์มโดยไม่ทำให้เกิดปัญหา ส่วนฟิล์มแบบรีดเย็นนั้นช่วยเรื่องการพิมพ์หลายชั้นแต่ก็มีปัญหาของตัวเอง เพราะต้องใช้เวลาในการเย็นตัวหลังพิมพ์ ซึ่งทำให้กระบวนการช้าลงอย่างมาก ฟิล์มรีดทันทีอย่าง FOREVER DTF Premium Matt สามารถขจัดความไม่แน่นอนเหล่านี้ได้ ผู้ใช้งานสามารถลอกฟิล์มออกได้ทันทีหลังกดลงบนผ้าโดยไม่ต้องรอ นั่นหมายถึงเวลาในการผลิตที่รวดเร็วขึ้นและผลลัพธ์ที่ดีกว่าทุกครั้ง แม้ผู้ใช้งานจะเป็นมือใหม่ก็ตาม

การพิจารณาความเข้ากันได้ของผ้า

การเลือกฟิล์ม DTF ที่เหมาะสม หมายถึงการใส่ใจในรายละเอียดว่าฟิล์มนั้นทำงานร่วมกับผ้าแต่ละชนิดอย่างไร เพื่อหลีกเลี่ยงปัญหาเช่น สีตก หรือภาพพิมพ์ลอกล่อน เราได้เห็นซ้ำแล้วซ้ำอีกว่าผ้าผสมโพลีเอสเตอร์ที่ใช้กันอย่างแพร่หลายในเสื้อผ้า ให้ผลลัพธ์ที่ดีเมื่อใช้ฟิล์ม DTF แบบลอกทันที ข่าวดีคือ ฟิล์มเหล่านี้ยึดติดได้ดีและรักษารสชาติสีสันสดใสไว้ได้แม้ผ่านการซักมาหลายครั้ง ซึ่งเป็นสิ่งที่ลูกค้าสังเกตและชื่นชอบ การใช้เวลาในการเลือกฟิล์มให้ตรงกับผ้าไม่ใช่แค่เพียงเพื่อให้สินค้าดูดีขึ้นเท่านั้น แต่ยังช่วยยืดอายุการใช้งานของสินค้าที่พิมพ์แล้ว และเปิดโอกาสให้ธุรกิจมีทางเลือกมากขึ้น เมื่อต้องสร้างสรรค์ดีไซน์เฉพาะที่คนอยากสวมใส่

ปัจจัยด้านความยั่งยืนในการเลือกฟิล์ม

ปัจจุบันมีผู้คนมากขึ้นให้ความสนใจต่อการผลิตที่ยั่งยืน ดังนั้นการเลือกใช้ฟิล์ม DTF ที่เป็นมิตรกับสิ่งแวดล้อมจึงกลายเป็นเรื่องสำคัญอย่างยิ่งสำหรับบริษัทต่าง ๆ รายงานฉบับล่าสุดจาก Eco Textile News ได้ชี้ให้เห็นว่า ปัจจุบันมีการพัฒนาเทคโนโลยี DTF ที่นำเสนอทางเลือกของหมึกและฟิล์มที่เป็นมิตรกับสิ่งแวดล้อมมากขึ้น ซึ่งช่วยลดผลกระทบต่อธรรมชาติ องค์กรที่เปลี่ยนมาใช้วัสดุเหล่านี้จะได้รับประโยชน์หลักสองประการ ประการแรก พวกเขาสามารถตอบสนองความต้องการของผู้บริโภคในปัจจุบันได้อย่างทันท่วงที เนื่องจากความยั่งยืนถือเป็นเรื่องสำคัญสำหรับผู้ซื้อจำนวนมาก ประการที่สอง การใช้ผลิตภัณฑ์ที่เป็นมิตรกับสิ่งแวดล้อมช่วยสร้างภาพลักษณ์ที่ดีให้กับแบรนด์ เพราะแสดงให้เห็นถึงความจริงใจในการใส่ใจต่อแนวทางการอนุรักษ์สิ่งแวดล้อม การเลือกใช้ฟิล์มที่ยั่งยืนไม่เพียงแต่ช่วยให้เป็นไปตามข้อกำหนดด้านสิ่งแวดล้อมเท่านั้น แต่ยังดึงดูดกลุ่มผู้บริโภคที่มีจิตสำนึกและชอบแบรนด์ที่มีค่านิยมตรงกันกับตนเอง ซึ่งจะช่วยสร้างความสัมพันธ์ที่แข็งแกร่งกับลูกค้าในระยะยาว

การเตรียมอนาคตด้วยเทคโนโลยี DTF Instant-Peel

การใช้งานใหม่ที่เกินขอบเขตของเครื่องแต่งกาย

เทคโนโลยี DTF แบบลอกออกทันทีไม่ได้จำกัดอยู่แค่เสื้อผ้าอีกต่อไป เราเริ่มเห็นมันปรากฏขึ้นทั่วสารทิศ โดยเฉพาะในสิ่งของอย่างเช่น เครื่องนอน ผ้าเช็ดตัว และแม้แต่ของแจกเล็กๆ น้อยๆ ตามงานแสดงสินค้า อะไรที่ทำให้สิ่งเหล่านี้เจ๋งขนาดนั้นล่ะ? ก็เพราะมันสามารถรองรับดีไซน์ที่ซับซ้อนมาก ซึ่งเป็นไปไม่ได้ด้วยวิธีการก่อนหน้านี้ ตอนนี้ผู้คนเริ่มนำมันไปใช้กับเคสโทรศัพท์ งานตกแต่งผนัง และสินค้าของตกแต่งอื่นๆ อีกสารพัด จุดเด่นที่แท้จริงคือความหลากหลายในการใช้งานของฟิล์ม DTF เหล่านี้ สำหรับธุรกิจที่กล้าคิดนอกกรอบ มีโอกาสทองรออยู่ในตลาดใหม่ๆ เหล่านี้ ธุรกิจที่ก้าวเข้าสู่ตลาดเร็ว จะได้ขยายขอบเขตการให้บริการของตนเอง ขณะเดียวกันก็ยังคงความได้เปรียบเหนือคู่แข่งที่ยังยึดติดกับแนวคิดแบบเดิมๆ

นวัตกรรมหมึกและฟิล์มที่ยั่งยืน

หมึกพิมพ์และฟิล์มที่ยั่งยืนสำหรับการพิมพ์แบบ DTF (Direct to Film) กลายเป็นสิ่งจำเป็น เนื่องจากผู้คนจำนวนมากมองหาทางเลือกที่เป็นมิตรต่อสิ่งแวดล้อม โรงพิมพ์ทั่วประเทศกำลังเปลี่ยนมาใช้วัสดุที่ย่อยสลายได้ทางชีวภาพและหมึกพิมพ์สูตรน้ำ เนื่องจากช่วยลดมลพิษ แต่ยังคงให้ผลลัพธ์ที่ดีบนเนื้อผ้า หมึกพิมพ์ทางเลือกที่เป็นมิตรต่อสิ่งแวดล้อมเหล่านี้บางรุ่นได้รับการรับรองมาตรฐานด้านสิ่งแวดล้อมอย่างเป็นทางการจากองค์กรที่ได้รับการยอมรับ ซึ่งทำให้โดดเด่นบนชั้นวางสินค้าและสร้างความเชื่อมั่นให้กับลูกค้าในระยะยาว บริษัทที่นำแนวทางปฏิบัตินี้ไปใช้จะพบว่าตนเองอยู่ในตำแหน่งที่ดีขึ้นในตลาดปัจจุบันที่ความยั่งยืนมีความสำคัญต่อผู้ซื้อ หลายธุรกิจรายงานว่ายอดขายเพิ่มขึ้นหลังจากเปลี่ยนมาใช้หมึกพิมพ์ และยังสามารถบอกเล่าเรื่องราวเกี่ยวกับการใส่ใจโลกโดยไม่กระทบต่อคุณภาพงานพิมพ์ของลูกค้าได้อีกด้วย

การปรับปรุงกระบวนการทำงานที่ขับเคลื่อนด้วยปัญญาประดิษฐ์

การเพิ่ม AI เข้าไปในกระบวนการทำงานของการพิมพ์ DTF ได้เปลี่ยนแปลงอย่างมากในประสิทธิภาพของการดำเนินงาน ดูจากสิ่งที่เกิดขึ้นในอุตสาหกรรมในปัจจุบัน ร้านค้าหลายแห่งต่างพบว่าระบบสามารถตรวจจับจุดที่อาจชะลอตัวลงก่อนที่มันจะเกิดขึ้นจริง มีการศึกษาหนึ่งที่กล่าวถึงในนิตยสาร Technology Review ชี้ให้เห็นว่าความสามารถในการคาดการณ์ลักษณะนี้ อาจช่วยลดเวลาที่เสียไปได้ราว 20% เมื่อองค์กรเริ่มใช้เครื่องมือวิเคราะห์ข้อมูลอัจฉริยะที่ขับเคลื่อนโดยปัญญาประดิษฐ์ พวกเขาก็จะมีการควบคุมที่ดีขึ้นในเรื่องเวลาการใช้งานวัสดุและตารางการผลิตบนสายพานการผลิต แต่ประโยชน์ที่แท้จริงนั้นยังมีมากกว่าแค่การประหยัดเงิน ธุรกิจที่นำเทคโนโลยีเหล่านี้มาใช้ พบว่าตนเองสามารถตอบสนองคำขอของลูกค้าได้รวดเร็วขึ้น พร้อมทั้งควบคุมต้นทุนให้อยู่ในระดับที่เหมาะสม สิ่งนี้เองจึงเป็นข้อได้เปรียบที่ชัดเจนเมื่อเทียบกับคู่แข่งที่ยังไม่ได้ลงทุนในความสามารถด้านการพิมพ์ DTF ของตนเอง

คำถามที่พบบ่อย

ข้อได้เปรียบหลักของฟิล์ม DTF แบบลอกออกทันทีคืออะไร?

ฟิล์ม DTF แบบลอกออกทันทีมีความแข็งแรงในการยึดเกาะสูง ทนต่อการซัก มีสีสันสดใสบนหลากหลายประเภทของเนื้อผ้า เพิ่มประสิทธิภาพในการทำงาน และรองรับความสามารถในการผลิตที่ขยายได้ เหมาะสำหรับเสื้อผ้าทั่วไปและช่วยให้ธุรกิจตอบสนองความต้องการที่หลากหลายของลูกค้าได้อย่างมีประสิทธิภาพ

เทคโนโลยีลอกทันทีช่วยปรับปรุงกระบวนการปรับแต่งอย่างไร?

เทคโนโลยีลอกทันทีลดเวลาในการรอระหว่างการพิมพ์และการใช้งาน ลดความเสี่ยงของการบิดเบือนดีไซน์ และเพิ่มความสะดวกในการใช้งาน โดยเฉพาะสำหรับธุรกิจขนาดเล็กและสตาร์ทอัพ

ฟิล์ม DTF แบบลอกทันทีเป็นมิตรต่อสิ่งแวดล้อมหรือไม่?

ใช่ การพัฒนาในเทคโนโลยี DTF ได้นำไปสู่ตัวเลือกหมึกและฟิล์มที่ยั่งยืนมากขึ้น เช่น หมึกที่ย่อยสลายได้ทางชีวภาพและหมึกชนิดน้ำ ซึ่งสนับสนุนความพยายามในการอนุรักษ์สิ่งแวดล้อมและตอบโจทย์แนวโน้มของตลาดที่เน้นความเป็นมิตรต่อสิ่งแวดล้อม

ฟิล์ม DTF แบบลอกทันทีเปรียบเทียบกับฟิล์มลอกแบบร้อนและเย็นอย่างไร?

ฟิล์มลอกทันทีสามารถจัดการได้ทันทีหลังจากพิมพ์เสร็จสิ้น เพิ่มประสิทธิภาพการทำงานและรักษาคุณภาพที่สม่ำเสมอโดยไม่จำเป็นต้องมีการระบายความร้อนเป็นเวลานานเหมือนฟิล์มลอกเย็น หรือการควบคุมเวลาอย่างแม่นยำเหมือนฟิล์มลอกร้อน