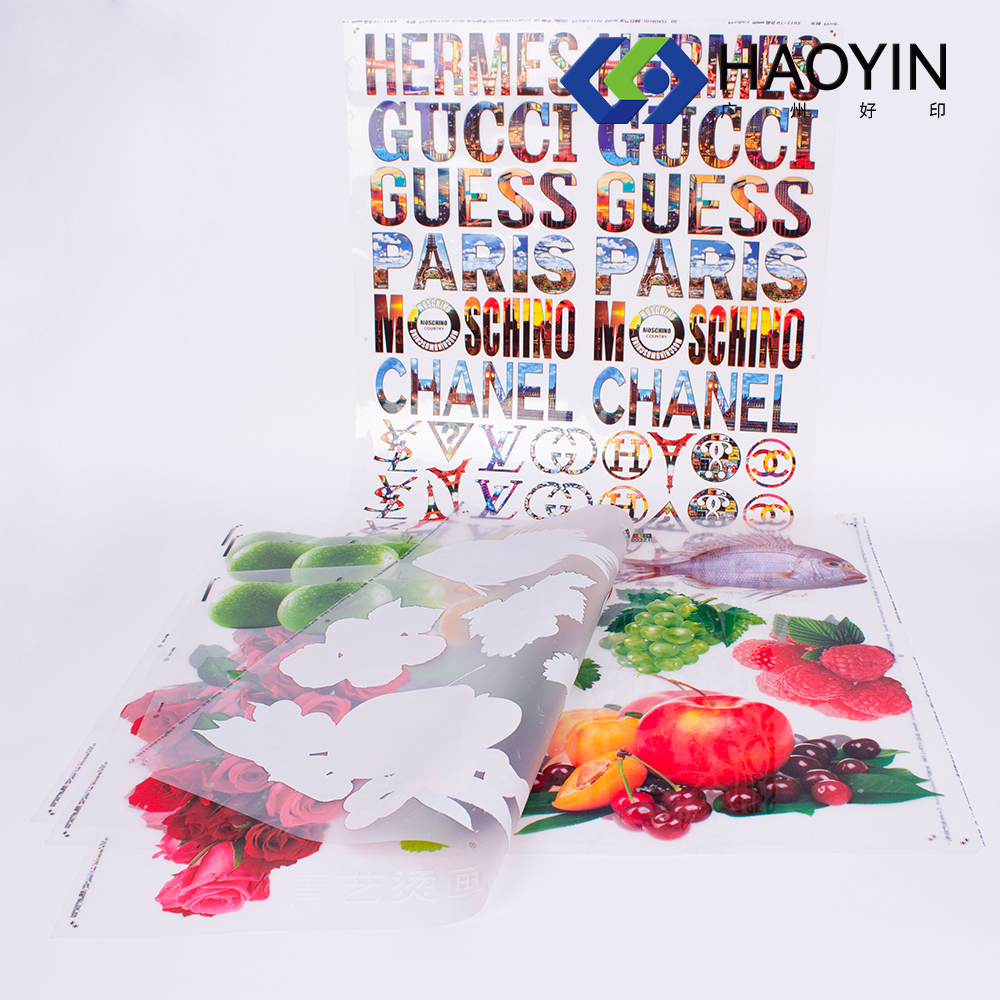

clear pet film

Clear PET film is a versatile polyester material that combines exceptional transparency with outstanding mechanical properties. This advanced polymer film serves as a crucial component in numerous industrial and consumer applications. Manufactured through a sophisticated extrusion process, clear PET film exhibits remarkable clarity, dimensional stability, and excellent barrier properties against moisture and gases. The film's molecular structure ensures superior tensile strength and durability while maintaining optical clarity that rivals glass. It features a unique combination of properties including heat resistance up to 150°C, chemical resistance to various solvents, and exceptional printability. The film's versatility extends to its thickness range, typically available from 12 to 350 microns, making it suitable for diverse applications. In packaging, it serves as an ideal material for food containers, beverage bottles, and protective coverings. The electronics industry utilizes clear PET film for display screens and flexible circuits, while the printing sector relies on it for high-quality graphics and labels. Its eco-friendly characteristics, including recyclability and reduced carbon footprint compared to alternative materials, align with contemporary sustainability requirements.