Understanding the Core Components of Direct-to-Film Printing

Direct-to-film (DTF) printing has revolutionized the garment decoration industry by offering a versatile and cost-effective solution for creating high-quality transfers. At the heart of this innovative technology lies a carefully selected array of DTF printing materials that work in harmony to produce vibrant, durable, and washfast designs. Whether you're new to DTF printing or looking to optimize your current process, understanding these essential materials is crucial for achieving professional results.

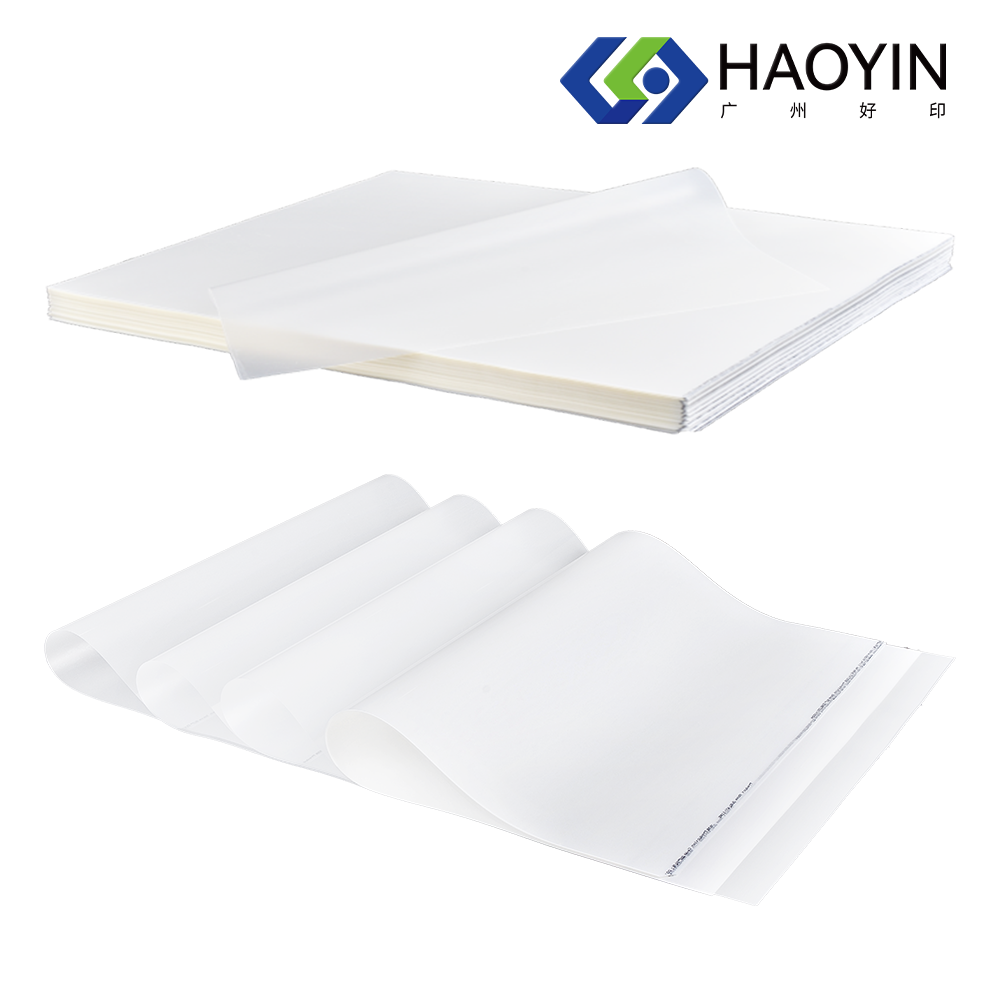

The Foundation: PET Film for DTF Printing

Characteristics of Quality PET Films

The polyethylene terephthalate (PET) film serves as the foundation for DTF printing materials. This specialized film features a unique coating that allows ink to adhere properly while maintaining stability throughout the printing process. High-quality PET films possess excellent dimensional stability, preventing warping or curling during heating. The film's surface must be perfectly smooth to ensure even ink distribution and sharp image reproduction.

Selecting the Right PET Film Thickness

PET films for DTF printing typically come in thicknesses ranging from 75 to 100 microns. The choice of thickness affects both the handling characteristics and the final transfer quality. Thicker films offer better stability during printing but may require more heat during transfer. Thinner films provide more flexibility but need careful handling to prevent damage. Professional print shops often stock multiple thicknesses to accommodate different fabric types and design requirements.

DTF Inks: The Color Carriers

Specialized Ink Formulations

DTF printing materials include specially formulated inks designed to bond effectively with both the PET film and the hot melt adhesive powder. These water-based pigmented inks contain unique binding agents that ensure excellent adhesion and color vibrancy. Unlike traditional textile inks, DTF inks must maintain their integrity through the powder application and heat transfer processes while providing superior washability.

Color Management and Performance

Professional DTF inks come in standard CMYK sets, often supplemented with white ink for opacity and brightness. The white ink plays a crucial role in creating vibrant designs on dark garments and must offer excellent coverage while maintaining flexibility after transfer. Color consistency and accurate reproduction are essential factors in selecting quality DTF inks.

Hot Melt Adhesive Powder: The Binding Element

Chemical Composition and Properties

The hot melt adhesive powder is perhaps the most critical among DTF printing materials, as it creates the permanent bond between the printed design and the fabric. This specialized powder consists of polyethylene and polyamide resins, carefully formulated to provide optimal adhesion strength while maintaining flexibility. The particle size distribution must be consistent to ensure even application and proper melting characteristics.

Application Techniques and Storage

Proper application of the adhesive powder requires precise control over temperature and coverage. The powder must be evenly distributed over the wet ink and carefully heated to achieve the desired adhesion properties. Storage conditions significantly impact powder performance, with humidity control being particularly important to prevent clumping and maintain flow characteristics.

Release Papers and Protection Sheets

Types of Release Materials

While often overlooked, release papers and protection sheets are essential DTF printing materials that protect both the equipment and the final product. Silicon-coated release papers prevent the transfer from sticking to heat press platens, while protection sheets help maintain even pressure distribution during the transfer process. These materials must withstand high temperatures while providing consistent release properties.

Optimal Usage Practices

Selecting the appropriate release materials and using them correctly can significantly impact transfer quality and production efficiency. Professional-grade materials often allow for multiple uses, reducing operational costs while maintaining consistent results. Regular replacement schedules and proper storage help maintain the integrity of these essential components.

Equipment Maintenance Supplies

Cleaning Solutions and Tools

Maintaining DTF printing materials and equipment requires specific cleaning solutions and tools designed for this technology. Printhead cleaners, film surface preparation solutions, and powder removal tools are essential for consistent quality and equipment longevity. These maintenance supplies must be compatible with all components while effectively removing residues and contaminants.

Preventive Maintenance Materials

Long-term success with DTF printing depends on regular preventive maintenance using appropriate materials. This includes specialized wipes, protective coatings for mechanical components, and calibration tools. Investment in quality maintenance supplies helps prevent costly downtime and ensures consistent print quality.

Frequently Asked Questions

What are the most critical factors in selecting PET film for DTF printing?

When choosing PET film, focus on coating quality, dimensional stability, and thickness appropriate for your application. The film should have consistent surface properties and be compatible with your specific printer and ink system. Additionally, consider the film's release characteristics and how well it handles the hot melt powder application process.

How does adhesive powder quality affect transfer durability?

The quality of hot melt adhesive powder directly impacts wash fastness, stretch resistance, and overall transfer durability. Premium powders offer better particle size consistency, optimal melting characteristics, and superior bonding strength. They also tend to provide better coverage and more consistent results across different fabric types.

What storage conditions are recommended for DTF printing materials?

Store DTF printing materials in a controlled environment with temperature between 68-77°F (20-25°C) and relative humidity between 40-60%. Keep PET films and powders in sealed containers away from direct sunlight. Inks should be stored according to manufacturer specifications, typically in a cool, dark place with regular agitation before use.