Understanding the Revolutionary Properties of PU Heat Transfer Vinyl

In the ever-evolving world of textile customization and garment decoration, PU heat transfer vinyl stands out as a remarkable innovation that has transformed the industry. This versatile material combines durability, flexibility, and ease of use, making it the go-to choice for both professional designers and DIY enthusiasts. Its unique composition and characteristics have revolutionized how we approach fabric customization, offering superior results that withstand the test of time.

The Science Behind PU Heat Transfer Vinyl

Chemical Composition and Structure

PU heat transfer vinyl is crafted from polyurethane, a sophisticated polymer that offers exceptional flexibility and resilience. The material consists of multiple layers, each serving a specific purpose in the transfer process. The adhesive layer ensures strong bonding with the fabric, while the carrier sheet maintains the vinyl's stability during handling and application. This carefully engineered structure contributes to the material's outstanding performance and longevity.

The molecular arrangement of PU heat transfer vinyl allows it to create a strong, permanent bond with fabric fibers when heat is applied. Unlike other materials, the polyurethane molecules form cross-links during the heating process, resulting in a durable connection that becomes part of the fabric rather than merely sitting on top of it.

Manufacturing Process Excellence

The production of PU heat transfer vinyl involves advanced manufacturing techniques that ensure consistent quality and performance. The material undergoes precise temperature control and coating processes to achieve the perfect thickness and adhesion properties. This attention to detail during manufacturing results in a product that delivers reliable results across various applications.

Quality control measures throughout the production process guarantee that each roll of PU heat transfer vinyl meets strict standards for thickness, flexibility, and adhesion strength. These rigorous manufacturing protocols ensure that users can consistently achieve professional-quality results in their projects.

Superior Performance Characteristics

Exceptional Durability and Longevity

One of the most impressive aspects of PU heat transfer vinyl is its remarkable durability. The material maintains its appearance and integrity through countless wash cycles, resisting fading, cracking, and peeling. This exceptional longevity makes it ideal for creating designs on frequently worn and washed items like sports uniforms, work wear, and everyday clothing.

The material's resistance to environmental factors such as UV radiation and chemical exposure further enhances its durability. This means designs created with PU heat transfer vinyl remain vibrant and intact even when subjected to outdoor conditions or regular cleaning with various detergents.

Unmatched Flexibility and Comfort

PU heat transfer vinyl offers superior flexibility that sets it apart from traditional materials. Once applied, it moves naturally with the fabric, maintaining comfort and preventing the stiff, plastic-like feel often associated with other vinyl products. This flexibility ensures that garments retain their original drape and wearability, making it perfect for athletic wear and fashion applications.

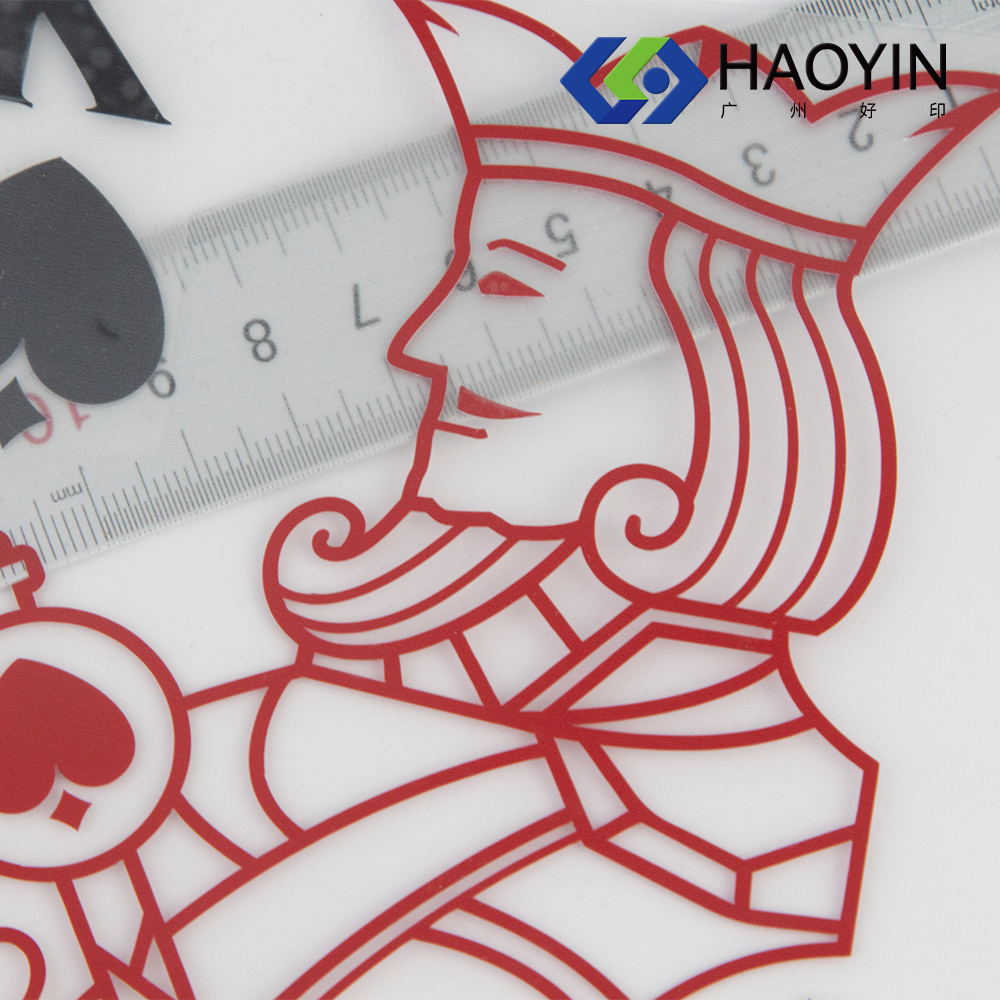

The material's thin profile contributes to its excellent flexibility, allowing for detailed designs that don't add bulk or weight to the garment. This characteristic is particularly valuable when creating intricate patterns or layered designs that require precise cutting and application.

Application Versatility and Design Potential

Wide Range of Compatible Fabrics

PU heat transfer vinyl demonstrates remarkable versatility in terms of fabric compatibility. It adheres effectively to cotton, polyester, blends, and even challenging materials like nylon and leather. This broad compatibility range opens up endless possibilities for creative expression across different textile products and applications.

The material's adaptability extends to various fabric textures and weights, from lightweight performance wear to heavy-duty workwear. This versatility makes PU heat transfer vinyl an invaluable tool for businesses that work with diverse textile products and need a reliable solution for all their customization needs.

Design Freedom and Creativity

The precision cutting capabilities of PU heat transfer vinyl enable the creation of intricate designs that would be impossible with traditional decoration methods. Whether working with text, logos, or complex artistic elements, the material maintains clean edges and fine details throughout the cutting and application process.

Modern cutting plotters can handle increasingly detailed designs in PU heat transfer vinyl, allowing for sophisticated visual effects and layered compositions. The material's consistent performance during cutting and weeding makes it possible to execute complex designs efficiently and reliably.

Frequently Asked Questions

What temperature should be used when applying PU heat transfer vinyl?

The optimal temperature for applying PU heat transfer vinyl typically ranges between 305°F to 320°F (150°C to 160°C). However, specific temperature requirements may vary slightly depending on the manufacturer and the type of fabric being used. It's essential to follow the manufacturer's recommended settings and perform test applications when working with new materials.

How long does PU heat transfer vinyl last on clothing?

When properly applied and cared for, PU heat transfer vinyl can last for 50+ washes while maintaining its appearance and adhesion. The actual lifespan depends on factors such as washing conditions, wear patterns, and the type of fabric it's applied to. Following care instructions and using appropriate washing temperatures will help maximize longevity.

Can PU heat transfer vinyl be layered?

Yes, PU heat transfer vinyl can be layered to create multi-colored or dimensional designs. However, it's important to use proper techniques and consider the overall thickness of the final design. Each layer should be applied separately, allowing proper cooling between applications to ensure optimal adhesion and prevent separation during wear and washing.