| Product Parameter: | |

| Product Name | 3D Thick Vinyl |

| Model Number | Q3-2 |

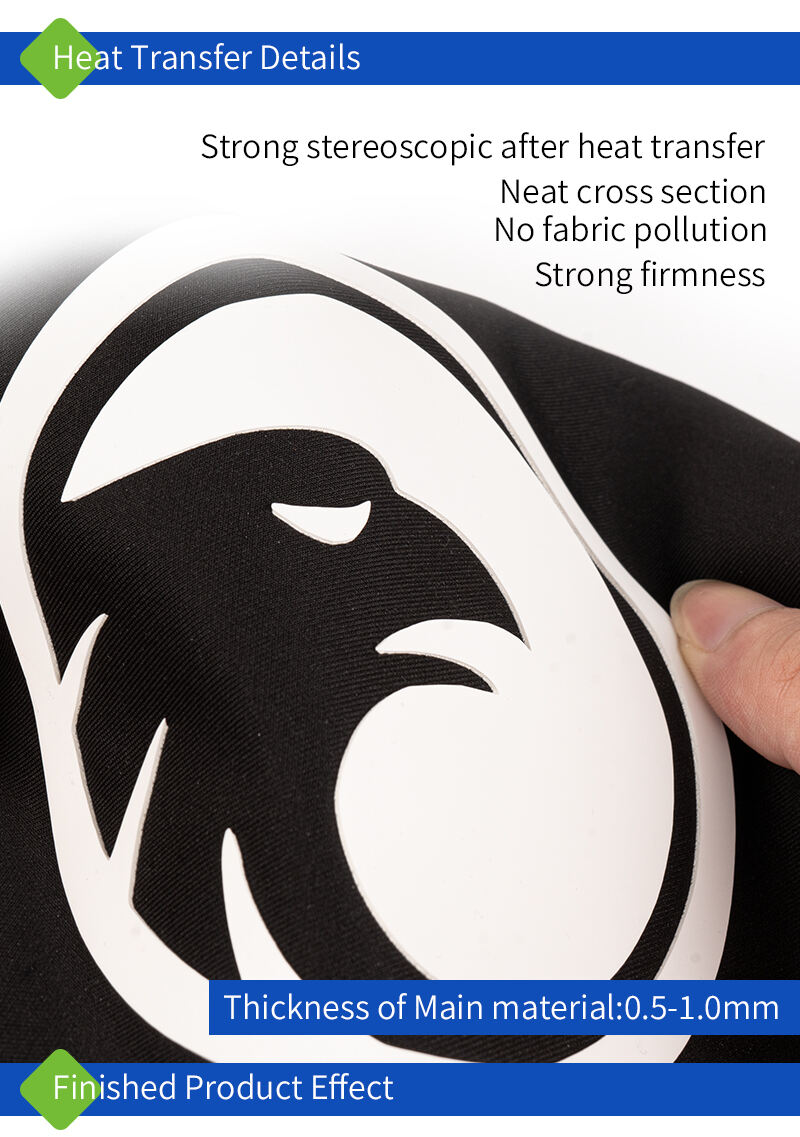

| Thickness | 500-1000um |

| Transfer Temperature | 160-165℃ |

| Transfer Force | 3-6kg |

| Transfer Time | 15-20s |

| Peel Method | Cool Peel |

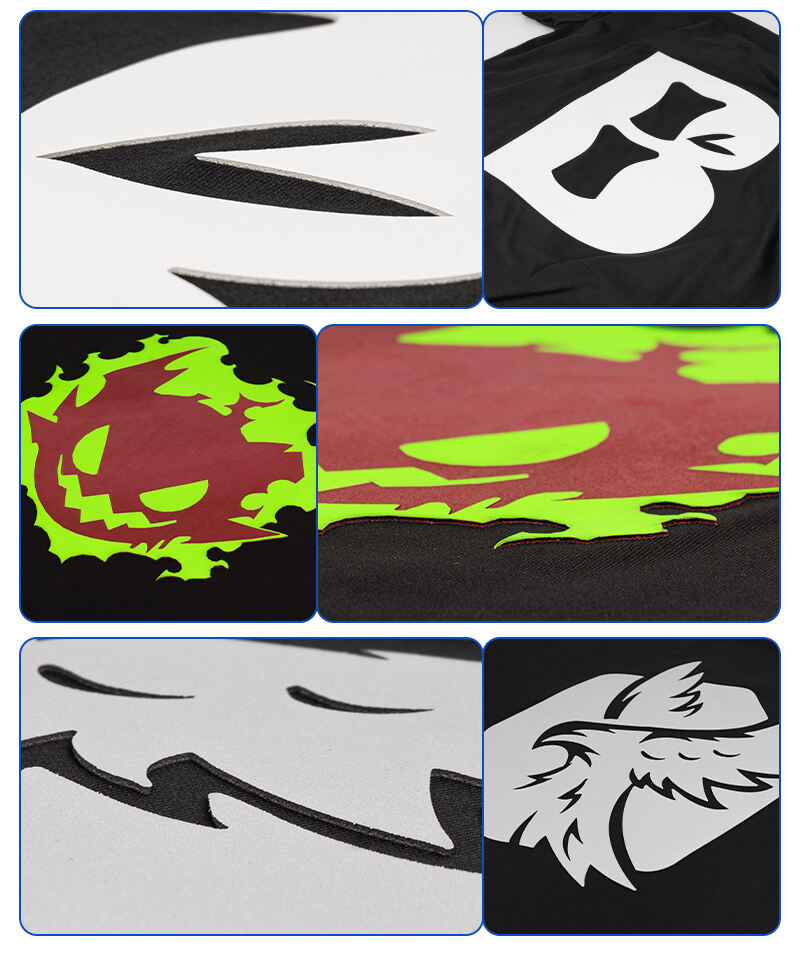

| Application | Apply to customize apparel, uniforms, bags, hats, shoes, sportswear, home textiles and personalized gifts. |

| Size | 45cm*25m/roll |

| Packaging Details | 1roll per carton, 5.5kg, 50cm*16cm*16cm |

| Leading Time | 3-7days |

| Sample | Available |

FAQ

1. What is 3D Thick Heat Transfer Vinyl?

It’s a heat transfer film with a raised surface that creates a 3D texture on fabrics. Ideal for premium clothing, fashion logos, and accessories.

2. What’s the difference between your thick HTV and regular PU HTV?

Our 3D film is 5–7 times thicker, providing a noticeable raised effect and stronger durability — perfect for high-end applications.

3. What fabrics can I use it on?

Cotton, polyester, fleece, canvas, and blended fabrics.

(Not suitable for nylon or waterproof materials.)

4. What are the best heat press settings?

150–160°C for 15–20 seconds with medium-high pressure. Use cold peel for best results.

5. Can it be printed on?

The standard film is not printable, but we also supply Printable 3D Thick HTV for eco-solvent printers.

6. Does it crack or peel after washing?

No — it’s designed to remain flexible and intact after more than 50 washes.

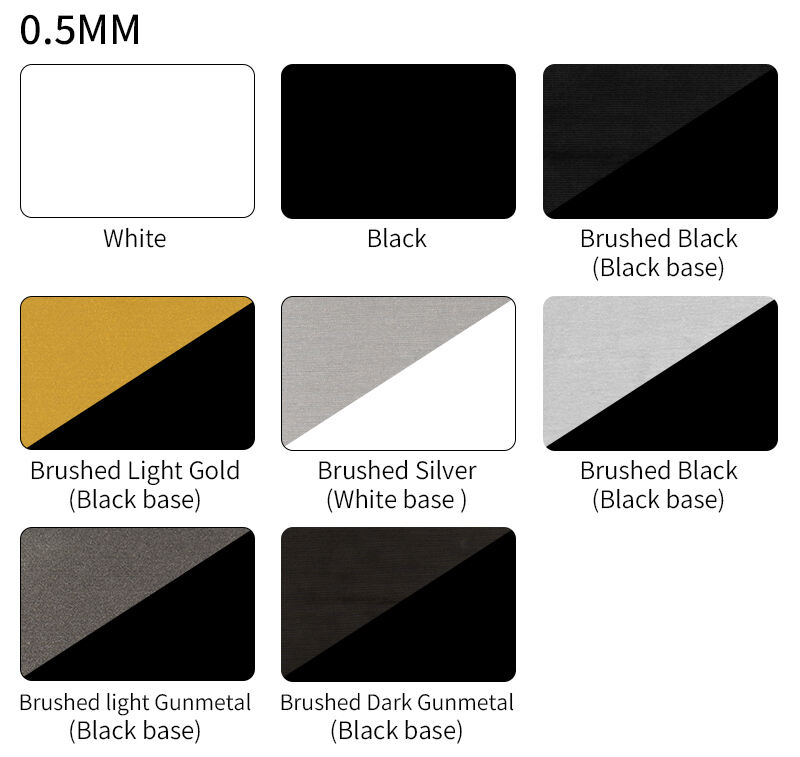

7. What sizes and colors are available?

50cm width, 25–50m rolls, and 20+ colors (matte, glossy, metallic). Custom colors available on request.

8. What’s your MOQ and delivery time?

MOQ is 50 rolls per color, with production time 7–15 days. Sample sheets are free for testing.

9. Can I get OEM packaging or brand logo printing?

Yes. We offer custom roll labels, logo printing, and private packaging for distributors.

10. Is it safe and eco-friendly?

Absolutely. Our materials are non-toxic, REACH and OEKO-TEX certified, suitable for children’s wear.