| Product Parameter: | |

| Product Name | DTF Film |

| Model Number | 88715 |

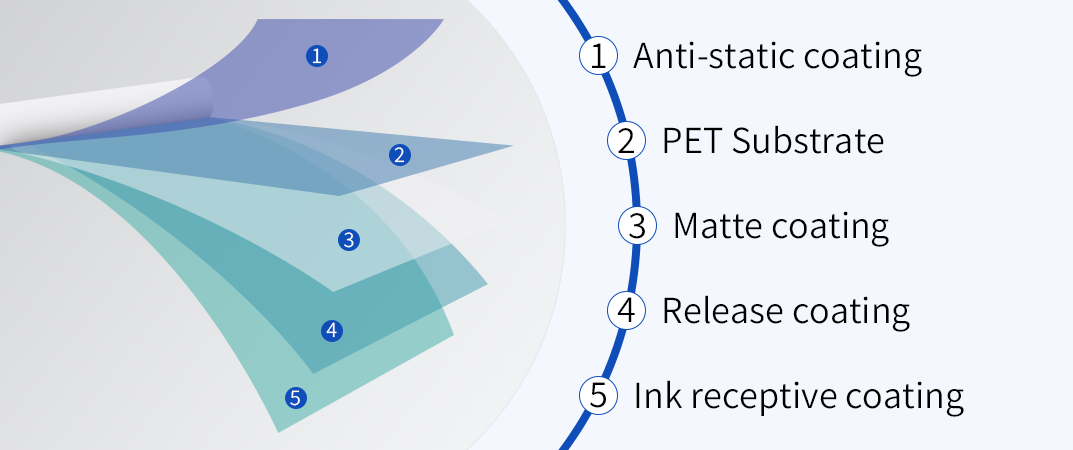

| Material | PET |

| Thickness | 75um |

| Coating Side | Double Side |

| White Ink Absorption | 90% |

| Antistatic | Normal |

| Transfer Temperature | 150-160℃ |

| Transfer Force | 3-6kg |

| Transfer Time | 8-15s |

| Peel Method | Cold |

| Application | Apply to customize apparel, uniforms, bags, hats, shoes, sportswear, home textiles and personalized gifts. |

| Size | 30/60CM*100M (Roll) A3/A4(Sheet) Large quantities accept customized specifications |

| Packaging Details | 2 roll per carton, 8kg,64cm*32cm*17.5cm |

| Leading Time | 3-7days |

| Sample | Available |

FAQ

1.What is DTF printing?

DTF printing (Direct to Film printing) is a modern heat transfer method where designs are printed onto DTF PET film and then transferred onto textiles. It works on cotton, polyester, blends, and many other fabrics, making it a versatile alternative to heat transfer vinyl (HTV) and screen printing.

2. What’s the difference between DTF and traditional heat transfer?

Wider fabric compatibility – suitable for cotton, polyester, blends, dark and light fabrics.

No cutting or weeding – unlike HTV, DTF transfers save time and labor.

High-resolution detail – supports gradients and vibrant full-color designs.

Durable & washable – strong adhesion, soft hand feel, and long-lasting prints.

3. What equipment do I need for DTF printing?

You will need:

DTF printer (XP600, I3200, 4720 printhead models)

DTF PET transfer film (hot peel or cold peel)

Hot melt adhesive powder

Curing oven / powder shaker machine

Heat press machine

👉 We also provide DTF supplies wholesale including film, powder, and inks.

4. What types of PET film are available?

Single matte / Double matte PET film

Hot peel DTF film / Cold peel DTF film

Moisture-proof & Anti-static film

Special DTF films: glitter, flock, glow-in-the-dark, 3D thick film, holographic effect.

5. What’s the difference between hot peel and cold peel film?

Hot Peel DTF film – peel right after pressing, faster production, matte finish.

Cold Peel DTF film – wait until it cools, offers better gloss and finer detail.

6. How many T-shirts can one roll of DTF film produce?

A 60cm x 100m roll of DTF transfer film can usually print 500–800 T-shirts (A4-size designs). Actual yield depends on design coverage.

7. How long can printed DTF transfers be stored?

Printed DTF transfers are best used within 2–3 weeks. Store them in a dry, cool, and dust-free environment to maintain adhesive quality and vivid colors.

8. Are DTF transfers washable?

Yes. DTF prints are highly durable and can last through 40–60 washes. For best results, wash garments inside out, use mild detergent, and avoid high-heat tumble drying.

9. What is your minimum order quantity (MOQ)?

Samples – available in 10meter.

Bulk orders – MOQ is typically 1 roll (60cm x 100m). Mixed orders are supported.

👉 We also supply DTF film wholesale with flexible MOQ for distributors.

10. What shipping methods do you offer?

We offer fast shipping worldwide via DHL, UPS, FedEx, as well as air freight and sea freight. We recommend the most cost-effective method depending on your volume and destination.

11. Do you offer custom DTF film services?

Yes. We provide OEM/ODM DTF film solutions, including:

Custom film width and length

Private label packaging and branding

Custom PET film rolls for specific printing needs

12. What if I receive defective products?

All DTF products are inspected before shipment. If you encounter any quality issues, please contact us within 7 days. We will arrange a replacement or refund.