best dtf film

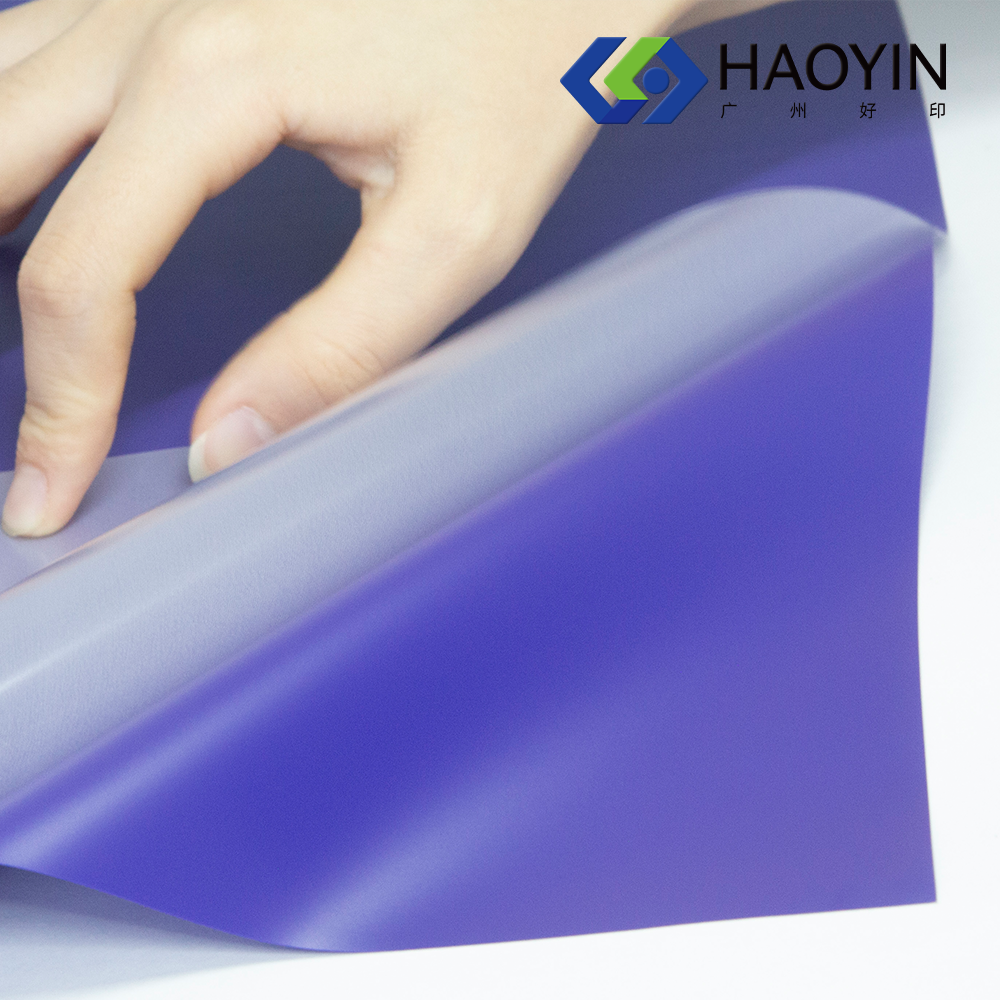

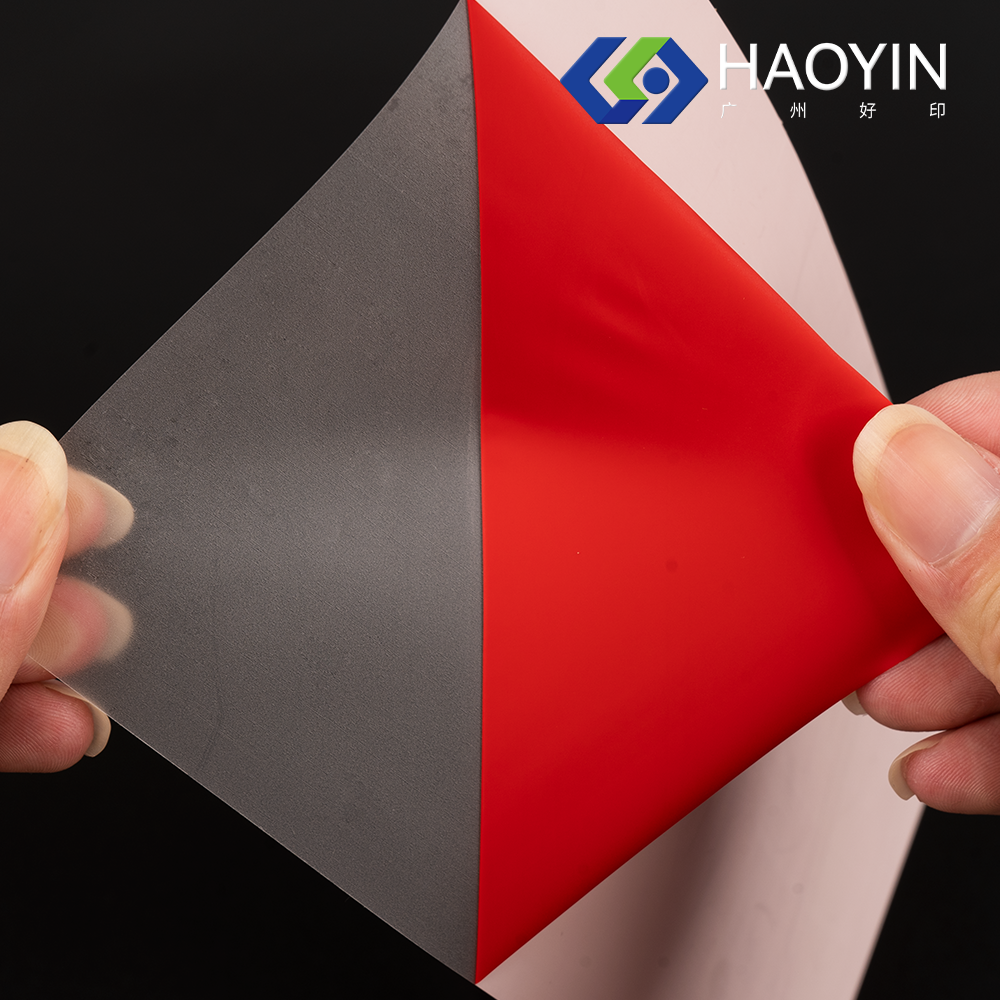

The best DTF (Direct to Film) transfer film represents a revolutionary advancement in garment printing technology, offering superior quality and versatility for textile decoration. This specialized polyethylene terephthalate (PET) film features a unique coating that enables excellent ink adhesion and transfer properties. The film's thickness typically ranges between 12-15 microns, providing optimal flexibility while maintaining durability during the printing process. Its advanced surface treatment ensures consistent ink distribution and sharp image reproduction, making it ideal for both simple designs and complex, multi-colored artwork. The film's chemical composition allows for excellent compatibility with water-based DTF inks, resulting in vibrant colors and precise detail retention. Its dimensional stability prevents warping or distortion during heat application, ensuring accurate transfer of designs onto various fabric types. The film's clear base allows for easy positioning and alignment during the transfer process, while its release properties ensure clean, complete transfer of designs without leaving residual film or adhesive on the garment.