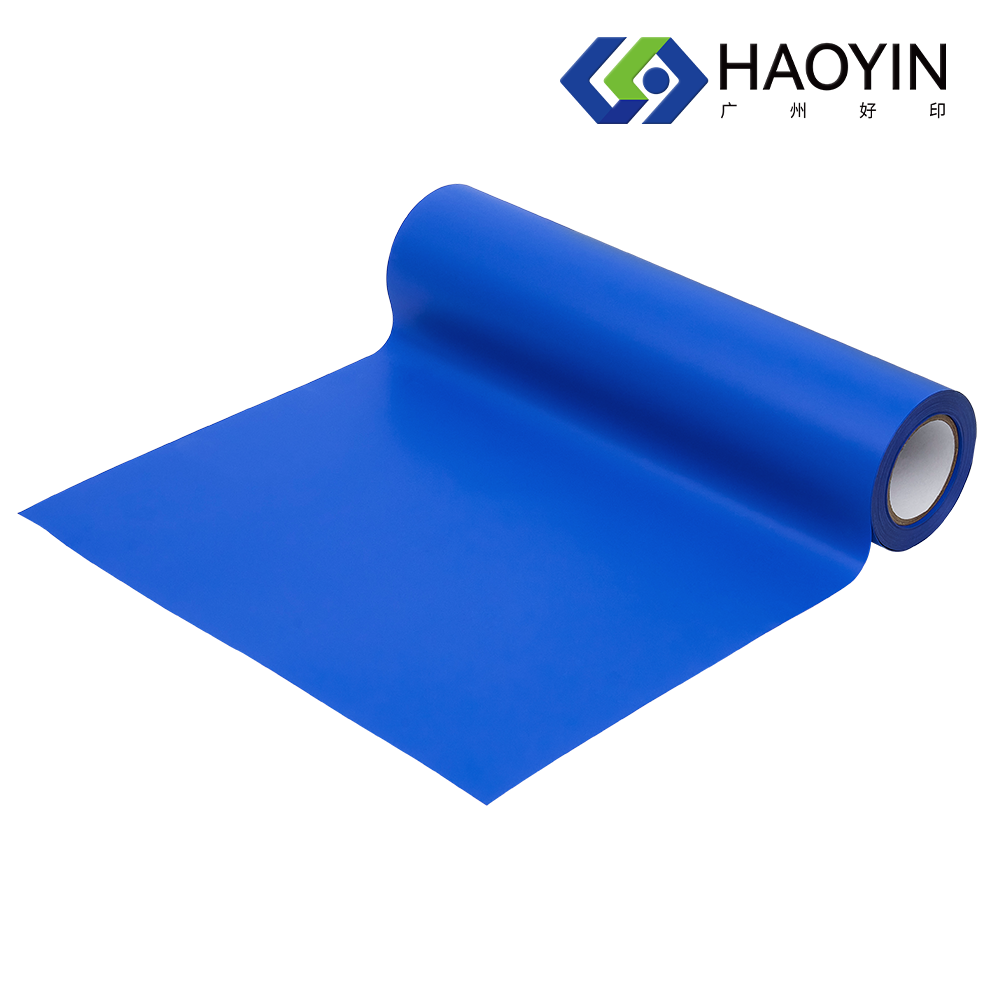

dtf transfer paper

DTF (Direct to Film) transfer paper represents a revolutionary advancement in textile printing technology, offering a versatile solution for transferring designs onto various fabric types. This specialized paper consists of a unique coating that enables direct printing of designs using DTF printers, followed by the application of hot melt adhesive powder. The transfer process involves printing the design in reverse on the film, applying the adhesive powder, curing it through heat, and then transferring it onto the desired fabric through heat press application. The paper's innovative composition allows for exceptional color vibrancy and durability, making it suitable for both light and dark fabrics. DTF transfer paper stands out for its ability to handle intricate designs and produce transfers that maintain their quality through multiple wash cycles. The material's structure ensures optimal ink absorption and adhesion, resulting in transfers that become part of the fabric rather than sitting on top of it. This technology has found widespread application in custom apparel printing, promotional merchandise production, and small-batch textile customization. The paper's compatibility with various fabric types, including cotton, polyester, nylon, and blended materials, makes it an invaluable tool for both commercial printing operations and DIY enthusiasts.