pet film manufacturers

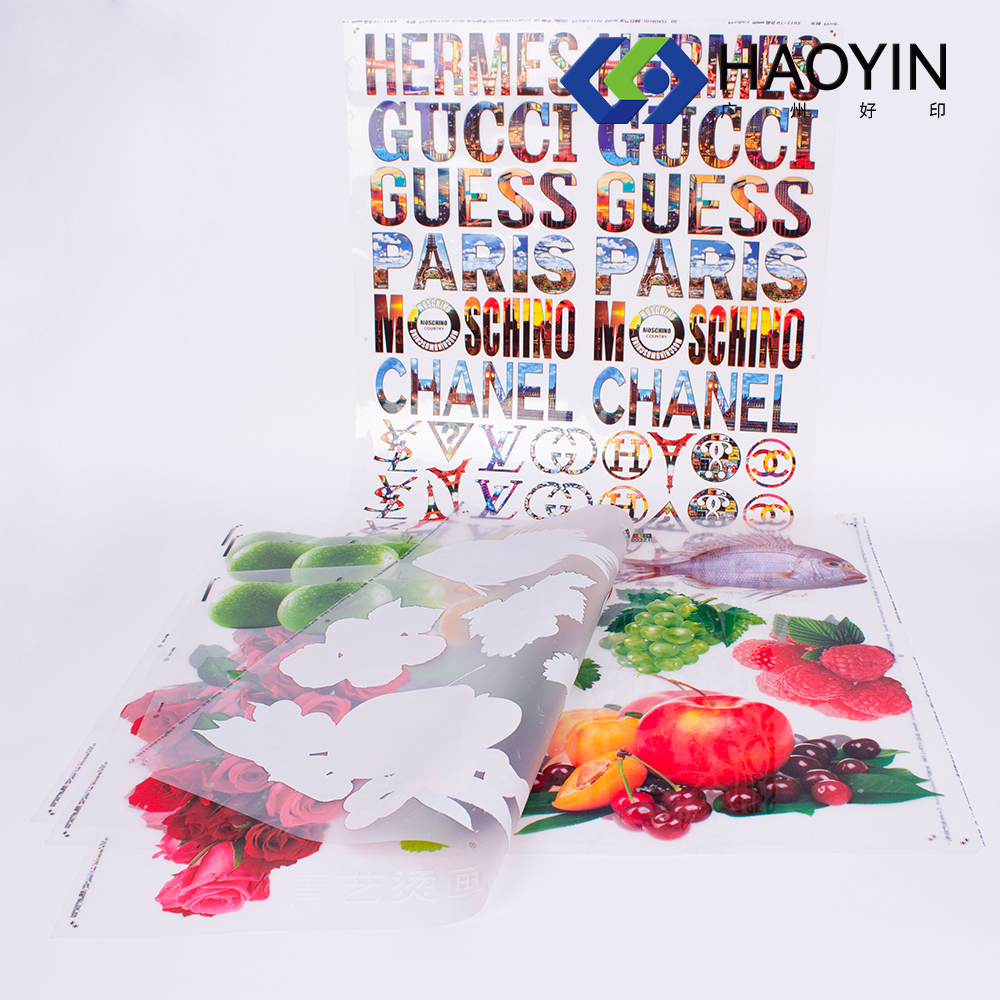

Pet film manufacturers play a crucial role in producing high-quality polyethylene terephthalate films that serve numerous industrial applications. These manufacturers utilize advanced extrusion and biaxial orientation processes to create versatile films with exceptional mechanical, thermal, and optical properties. Modern pet film manufacturing facilities employ state-of-the-art technology to ensure precise thickness control, superior surface quality, and consistent material properties throughout the production process. These manufacturers offer various grades of PET films, including transparent, metallized, and specialty coated variants, catering to diverse industry requirements. The manufacturing process involves careful selection of raw materials, sophisticated quality control measures, and rigorous testing protocols to maintain product excellence. Advanced production lines enable manufacturers to produce films ranging from ultra-thin to thick gauges, with capabilities to customize properties such as heat resistance, barrier protection, and surface treatments. These facilities also implement sustainable practices, often incorporating recycled materials and energy-efficient processes to minimize environmental impact. The global network of pet film manufacturers ensures steady supply chains and competitive pricing, while continuous research and development efforts drive innovation in film properties and applications.