pvc heat transfer

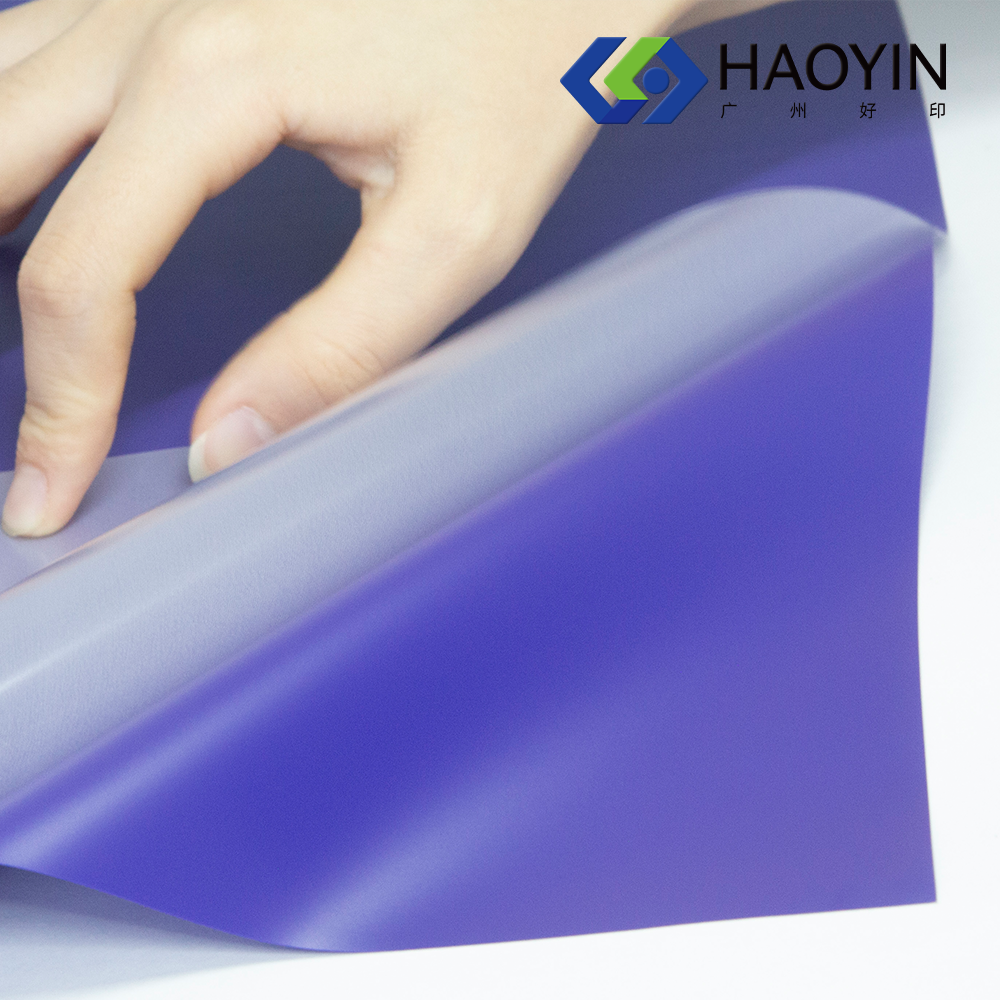

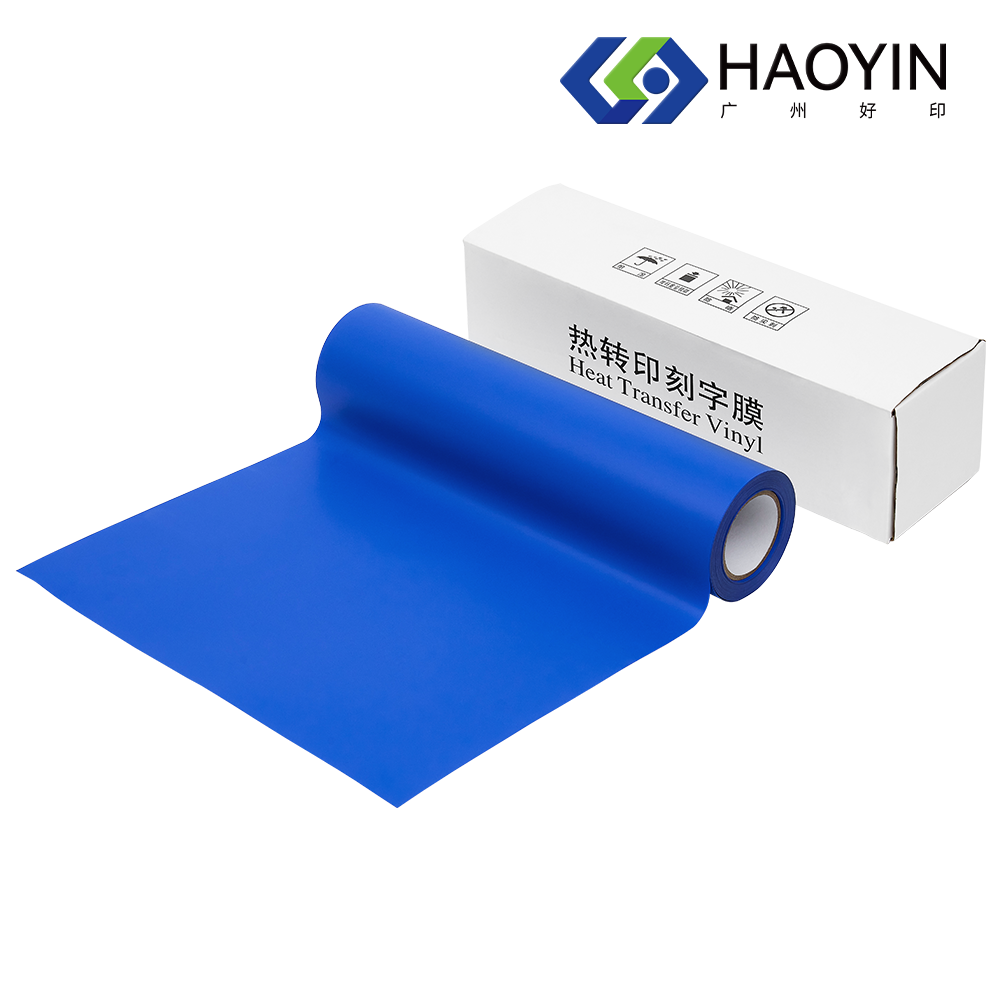

PVC heat transfer technology represents a sophisticated method of applying designs and graphics onto various surfaces through the combination of heat and pressure. This versatile process involves the use of specialized PVC materials that, when subjected to specific temperature and pressure conditions, bond permanently with the target surface. The process begins with the creation of a design using compatible inks on PVC transfer paper or film, which is then positioned on the desired surface. When heat is applied, typically between 300-350 degrees Fahrenheit, the PVC material undergoes a controlled melting process, allowing the design to transfer and bond with the substrate. This technology has revolutionized customization across multiple industries, offering exceptional durability and color vibrancy. The process is particularly effective on textiles, plastics, and other synthetic materials, making it ideal for apparel decoration, promotional items, and industrial applications. The precision of modern PVC heat transfer equipment ensures consistent results, with advanced temperature control systems and pressure regulation mechanisms guaranteeing optimal transfer conditions. This technology also accommodates various design complexities, from simple text to intricate multicolor patterns, while maintaining excellent edge definition and color accuracy.