PET (polyester) printed film is a high-precision, durable transfer material widely used in heat transfer applications for garments, bags, footwear, and other industries. The main printing methods include:

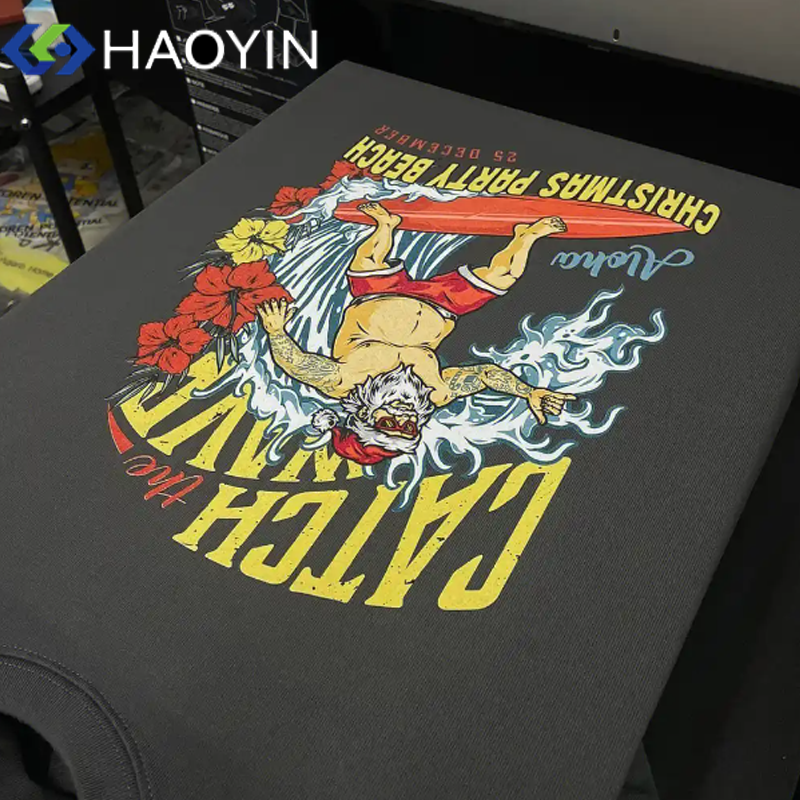

Process: Uses UV or water-based ink to print directly on PET film without plate-making.

Advantages:

Ideal for small batches and customized designs with flexible production.

Capable of high-precision, gradient-rich patterns (e.g., photorealistic effects).

White ink + color ink combination, perfect for dark fabrics.

Disadvantages: Higher per-unit cost, suitable for mid-to-high-end markets.

Process: Traditional four-color (CMYK) printing on PET film, requiring plate-making.

Advantages:

Cost-effective for mass production.

Stable color output, suitable for standardized orders (e.g., corporate uniforms).

Disadvantages:

Cannot print white ink alone; dark fabrics require an additional white adhesive layer.

High plate-making cost, not economical for small batches.

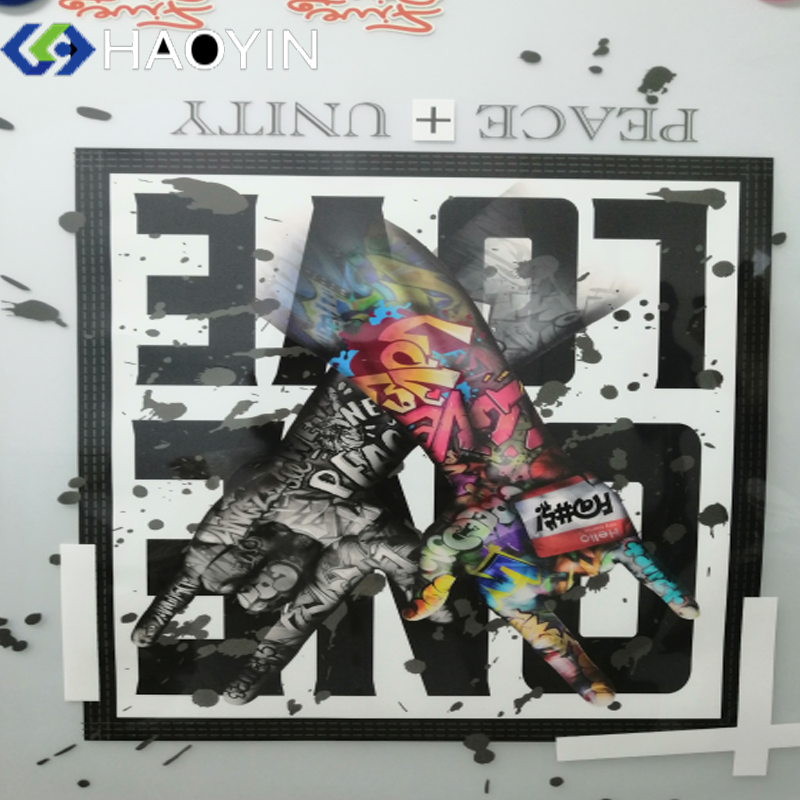

Process: Ink is manually or mechanically scraped onto PET film through a mesh screen.

Advantages:

Thick ink layers with high color saturation.

Suitable for single-color or spot-color designs (e.g., logos, text).

Disadvantages:

Not ideal for complex gradient patterns.

Plate-making is cumbersome, and multi-color registration is less precise.

Process: The design is first printed on transfer paper and then heat-pressed onto PET film.

Advantages:

Vibrant colors, ideal for synthetic fabrics.

Disadvantages:

Only suitable for light or white PET film; poor performance on dark backgrounds.

5.Summary:

High-end customization: Opt for digital inkjet printing (e.g., Discharge ink solutions).

Mass production orders: Offset printing + white-backed PET film is the optimal choice.

Special effects: Combine with screen printing (thick ink layers) or 3D heat transfer techniques.

Mastering these key points can significantly enhance the competitiveness and profitability of PET printed film products!

Hot News

Hot News2025-11-20

2025-11-13

2025-11-06

2025-10-30

2025-10-23

2025-10-16