Three crucial points about heat transfer vinyl (HTV) application!

Heat transfer vinyl involves using a heat press machine to apply pressure and heat, transferring designs onto the target fabric. During this process, several factors require attention. Engineers from HaoYin—with 29 years of expertise in HTV R&D—highlight the three critical aspects of heat pressing:

HTV application consists of three stages: Pre-pressing, Pressing, and Post-pressing.

1. Pre-Pressing: Preparation Matters

Before purchasing heat transfer vinyl, consult with sales or customer service to specify:

The type of fabric you’ll be applying the vinyl to.

Recommended settings: temperature, pressure, and pressing time.

The type of heat press machine (e.g., laser cutter, DIY iron, or professional heat press).

Always clarify these details before buying to ensure optimal results.

2. Pressing: Correct Application Technique

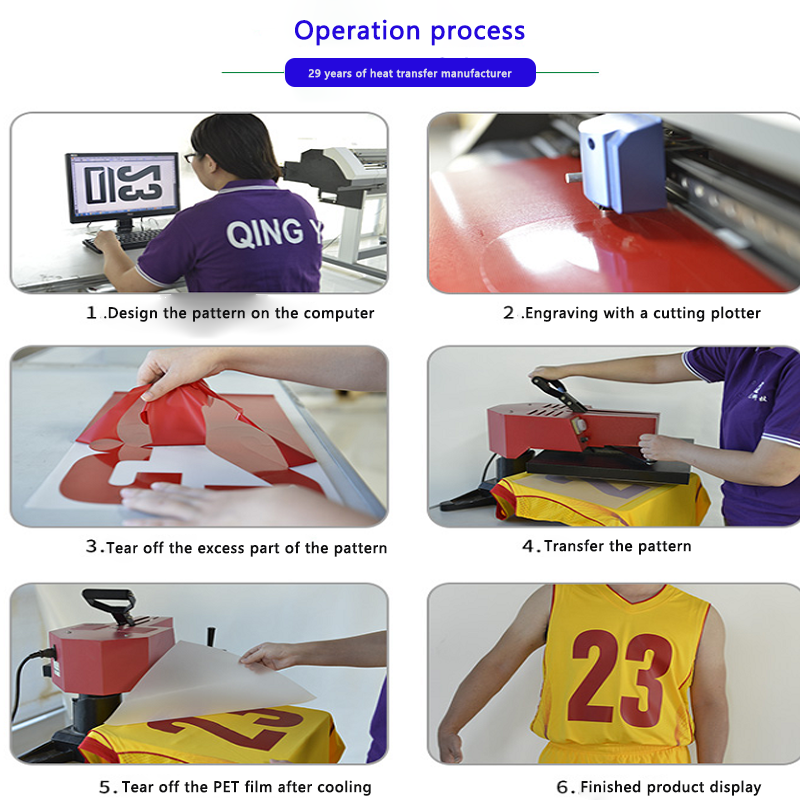

As shown in the diagram above, follow the proper heat pressing procedure to avoid errors.

3. Post-Pressing: Finishing Steps

Peeling Method: HTV can be cold peel or warm peel—confirm this with the supplier beforehand.

Test First: Always do a sample test before large-scale production.

Monitor Key Factors: Time, temperature, and pressure must remain consistent for quality results.

By addressing these three stages, you can achieve professional, long-lasting heat transfer vinyl applications.

Hot News

Hot News2025-08-28

2025-08-18

2025-08-11

2025-08-04

2025-07-25

2025-07-23