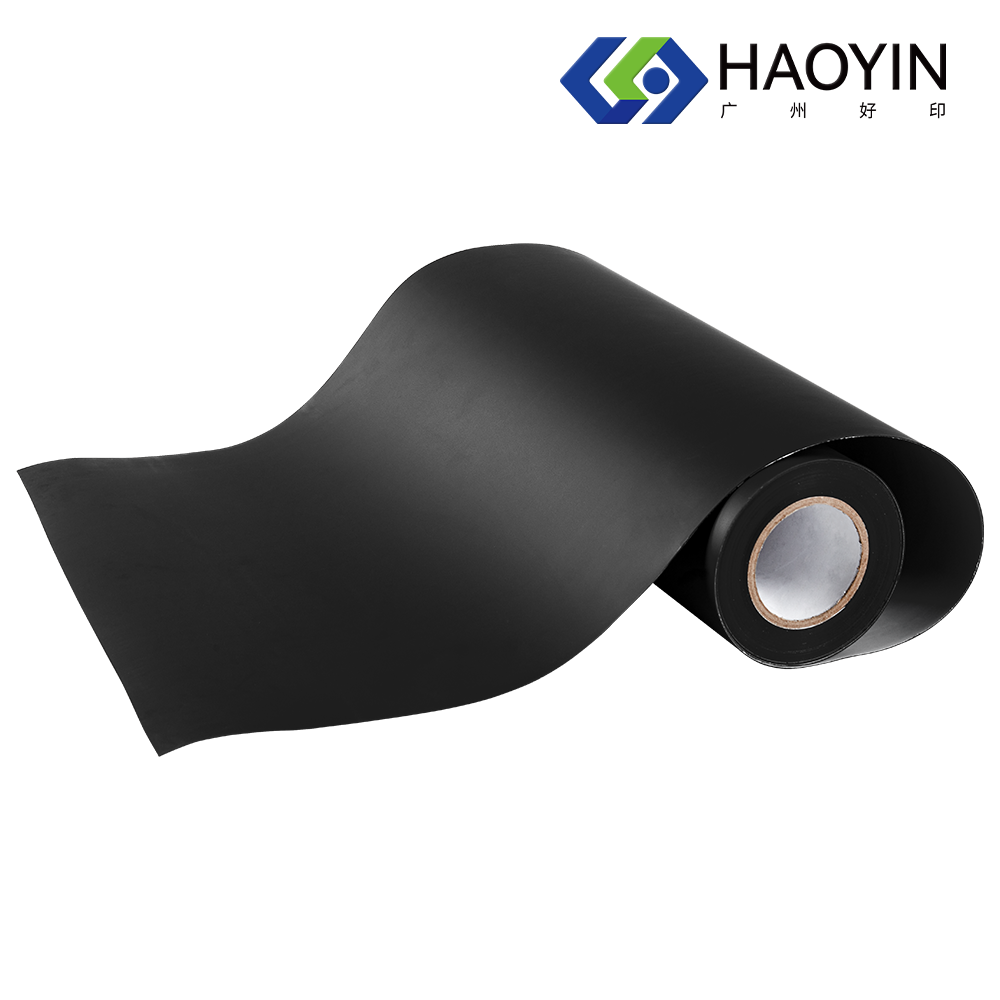

best dtf powder

DTF (Direct to Film) powder is a revolutionary component in the digital textile printing industry, specifically engineered for superior adhesion and durability. This advanced powder formulation serves as a crucial binding agent between the printed design and fabric substrate. The best DTF powder features precisely calibrated particle sizes, typically ranging between 20-40 microns, ensuring optimal coverage and consistent performance. It's composed of specialized hot-melt adhesive materials that activate at specific temperature ranges, usually between 160-180°C. The powder's unique chemical composition allows it to melt uniformly, creating a strong, flexible bond that withstands multiple wash cycles while maintaining image quality. Modern DTF powder formulations include advanced anti-static properties to prevent clumping and ensure smooth application. The powder's molecular structure is designed to provide excellent elasticity, making it ideal for stretchable fabrics while preventing cracking or peeling. Additionally, premium DTF powder incorporates UV-resistant properties, enhancing the longevity of printed designs when exposed to sunlight and environmental factors.