burgundy glitter heat transfer vinyl

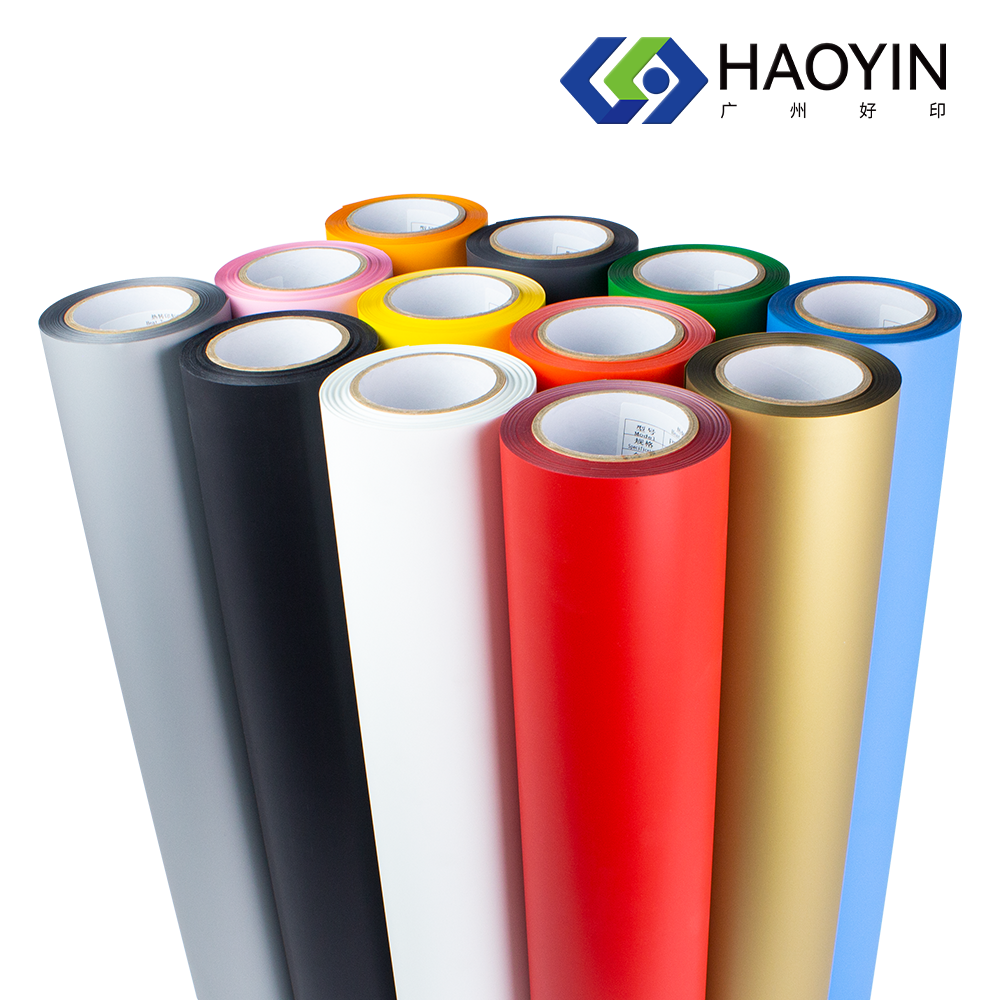

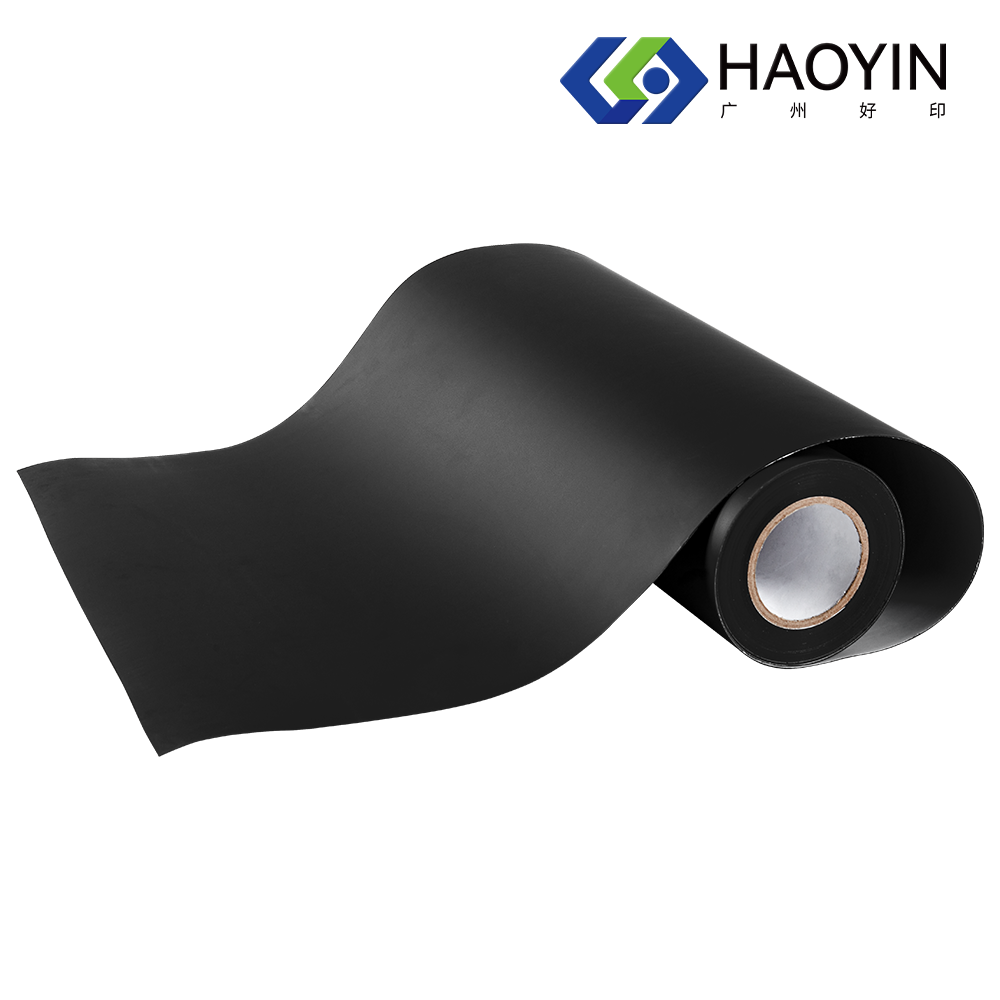

Burgundy glitter heat transfer vinyl represents a premium crafting material that combines sophisticated aesthetics with practical functionality. This specialized vinyl features a distinctive burgundy base infused with reflective glitter particles, creating a captivating sparkle effect that adds depth and dimension to any project. The material is specifically engineered for heat transfer applications, featuring a pressure-sensitive carrier that ensures precise cutting and easy weeding. The vinyl's composition includes a high-quality adhesive layer that activates under heat, forming a durable bond with various fabric types including cotton, polyester, and poly-cotton blends. With a thickness of approximately 300 microns, this heat transfer vinyl offers excellent coverage while maintaining flexibility and comfort in the finished product. The material's unique formulation allows for detailed designs and intricate patterns, making it ideal for both large-scale productions and intricate custom projects. Each roll comes with a clear carrier sheet that protects the glitter surface and facilitates proper alignment during application. The vinyl's heat-activated adhesive requires specific temperature settings, typically between 305-320°F, and pressure application for 10-15 seconds to achieve optimal results.