color print pu

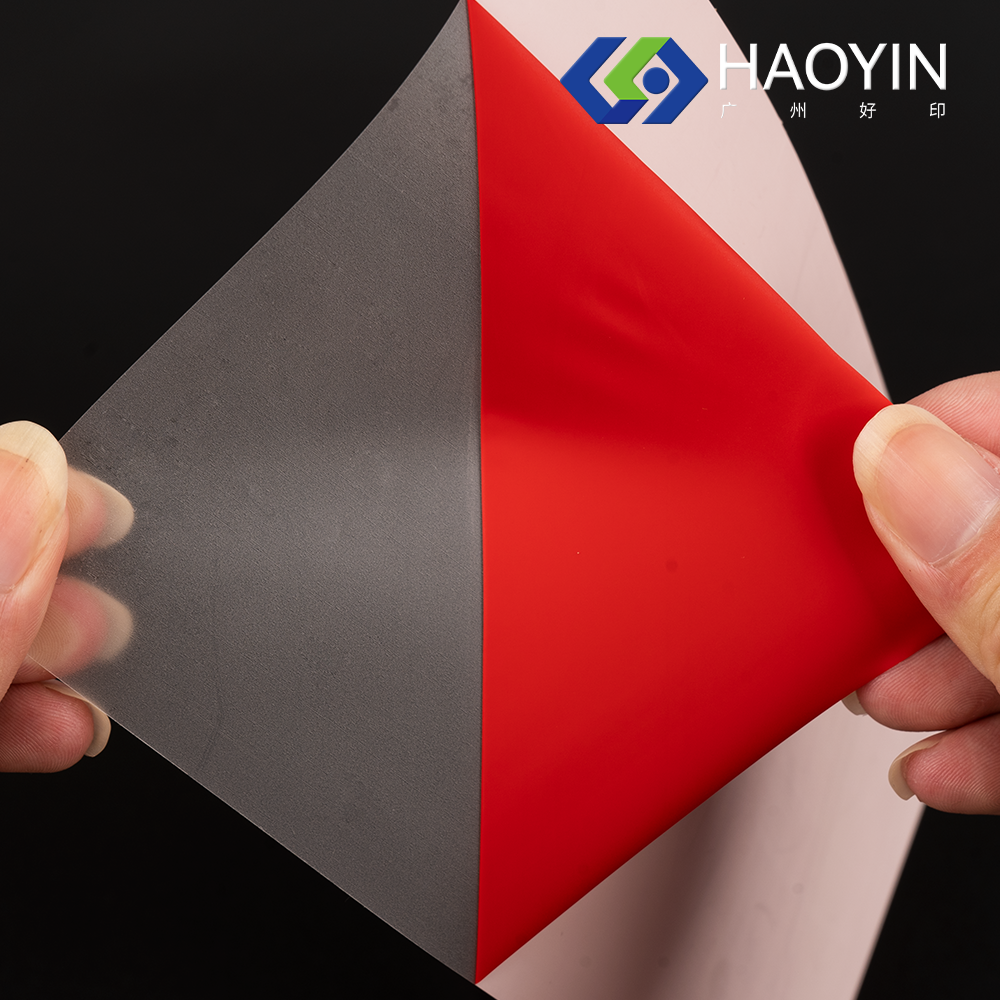

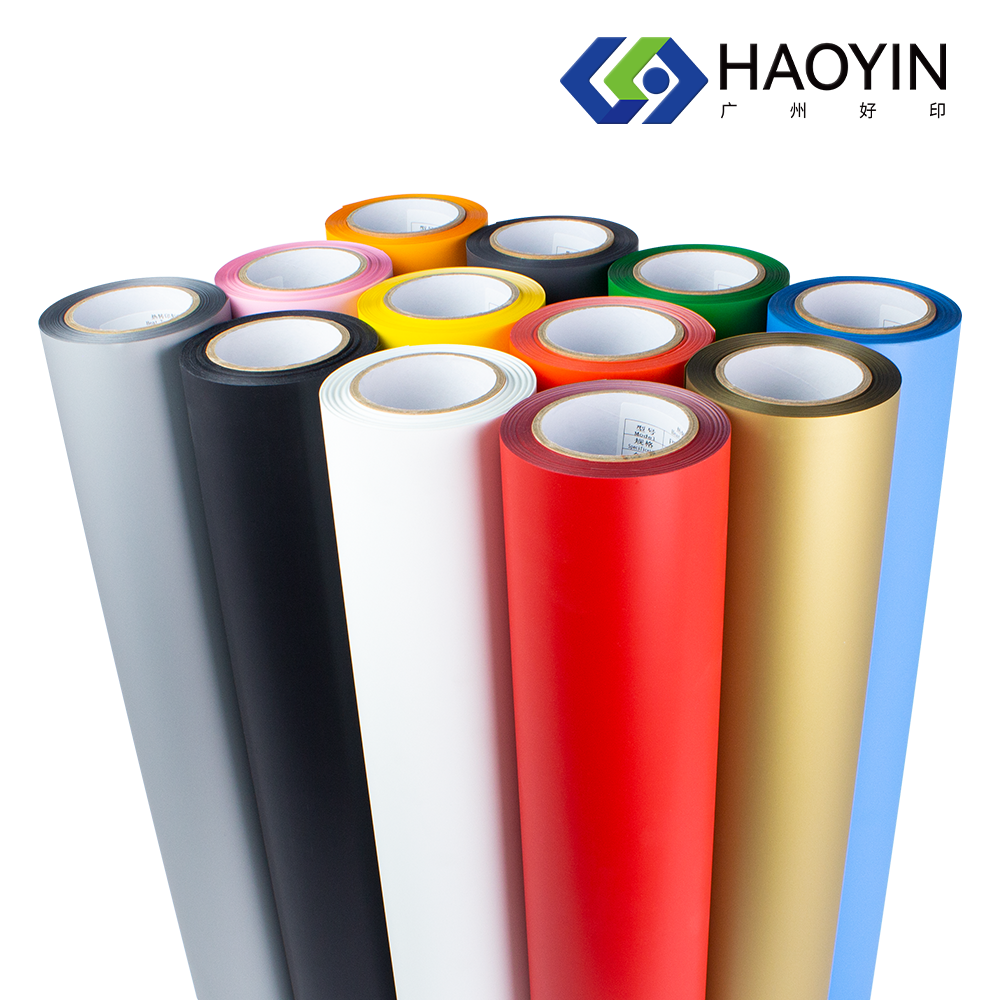

Color print PU (polyurethane) represents a revolutionary advancement in material technology, combining aesthetic appeal with functional durability. This innovative material features a specialized printing process that allows for vibrant, long-lasting color designs to be permanently embedded into the polyurethane surface. The manufacturing process involves a sophisticated combination of digital printing technology and chemical bonding techniques, ensuring that the printed patterns remain intact even under significant wear and tear. The material offers exceptional flexibility and resilience, making it ideal for various applications across multiple industries. Its water-resistant properties and ability to maintain color integrity under UV exposure make it particularly valuable for outdoor applications. The color print PU can be customized with virtually any design, pattern, or logo, offering unprecedented creative freedom while maintaining the material's core structural integrity. Its seamless integration of decorative elements with functional properties has made it a preferred choice in automotive interiors, fashion accessories, furniture upholstery, and industrial applications. The material's eco-friendly characteristics, including reduced VOC emissions during production and potential recyclability, align with contemporary sustainability requirements.