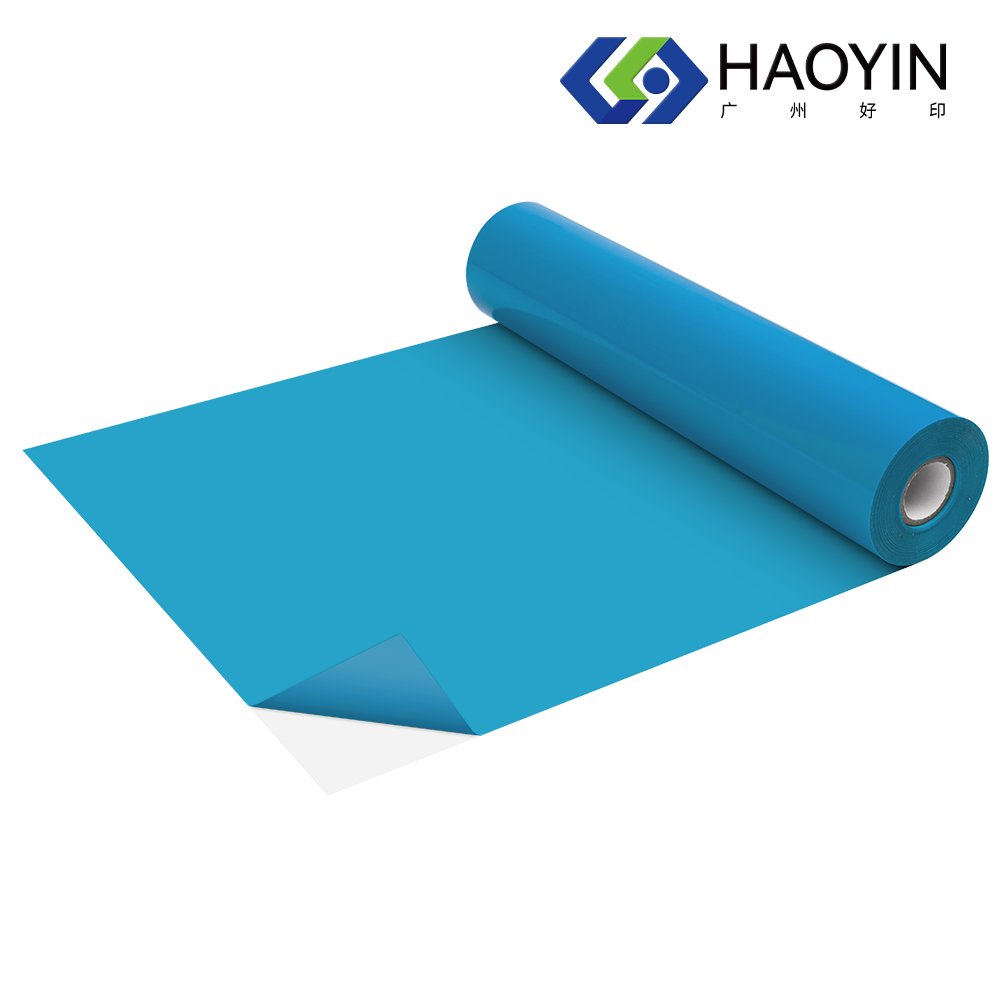

pu htv

PU HTV (Polyurethane Heat Transfer Vinyl) represents a significant advancement in garment decoration technology, offering a versatile and durable solution for custom apparel design. This innovative material consists of a polyurethane-based film that adheres to fabric through heat application, creating lasting designs that withstand multiple washes and wear. The material features a pressure-sensitive carrier that enables precise cutting and weeding, making it ideal for both simple and intricate designs. PU HTV is compatible with a wide range of fabric types, including cotton, polyester, cotton-poly blends, and even some synthetic materials. It offers exceptional flexibility and stretch recovery, ensuring that designs maintain their integrity even on frequently stretched fabrics. The material's thickness typically ranges from 80 to 100 microns, providing a lightweight feel that doesn't compromise the garment's natural drape. What sets PU HTV apart is its ability to create designs with a soft, matte finish that feels like part of the fabric rather than sitting on top of it. The application process is straightforward, requiring only a heat press or household iron, making it accessible for both professional and DIY applications.