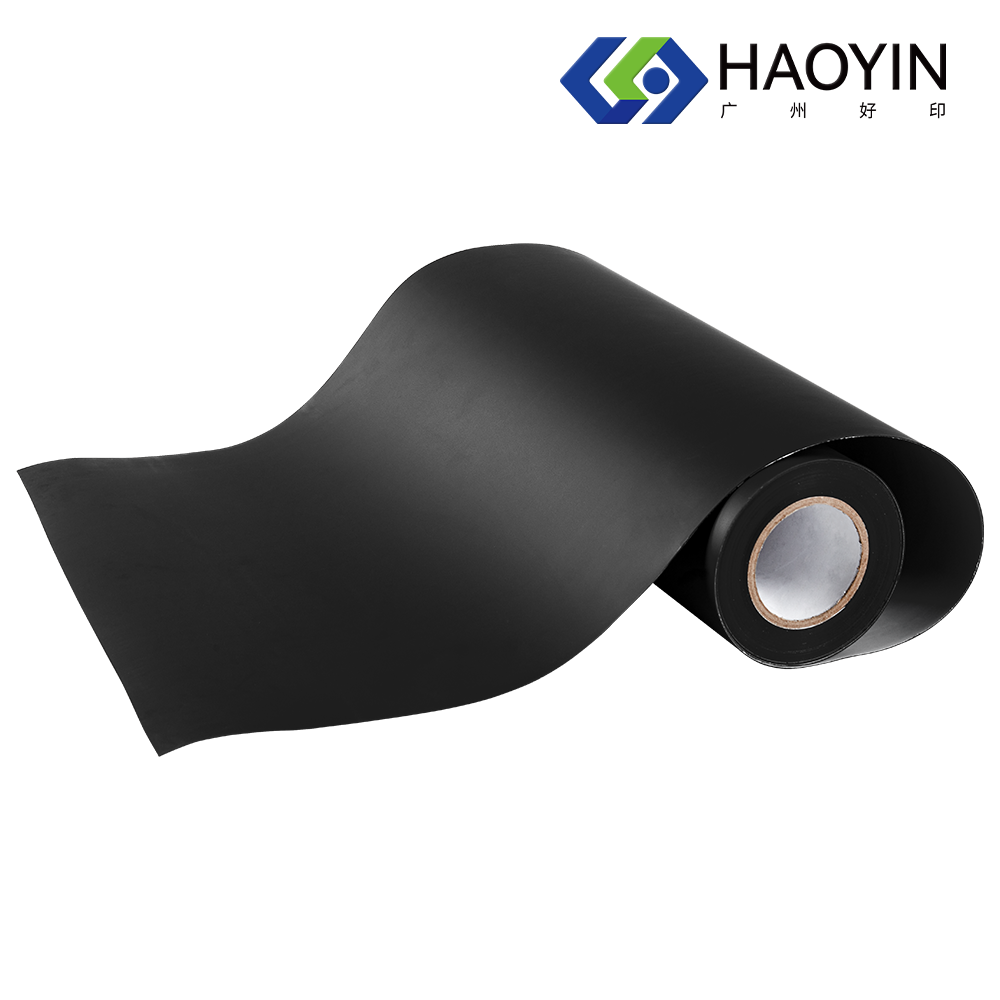

custom heat transfer vinyl

Custom heat transfer vinyl represents a versatile and innovative material designed for creating personalized designs on various fabric surfaces. This specialized vinyl consists of a multi-layered structure that includes a carrier sheet, adhesive layer, and the decorative vinyl layer itself. The material utilizes advanced thermal bonding technology to permanently adhere designs to fabrics when exposed to specific heat and pressure conditions. Available in an extensive range of colors, finishes, and textures, custom heat transfer vinyl enables users to create intricate designs, logos, text, and patterns that withstand multiple washes while maintaining their original appearance. The technology behind this product involves precision-cut designs that can be easily weeded and transferred using standard heat press equipment, making it accessible for both professional decorators and DIY enthusiasts. The material's molecular structure is engineered to create a strong, lasting bond with fabric fibers, ensuring durability and resistance to peeling, cracking, or fading over time. Additionally, modern custom heat transfer vinyl incorporates eco-friendly components and meets safety standards for application on clothing items that come into direct contact with skin.