dtf powder and film

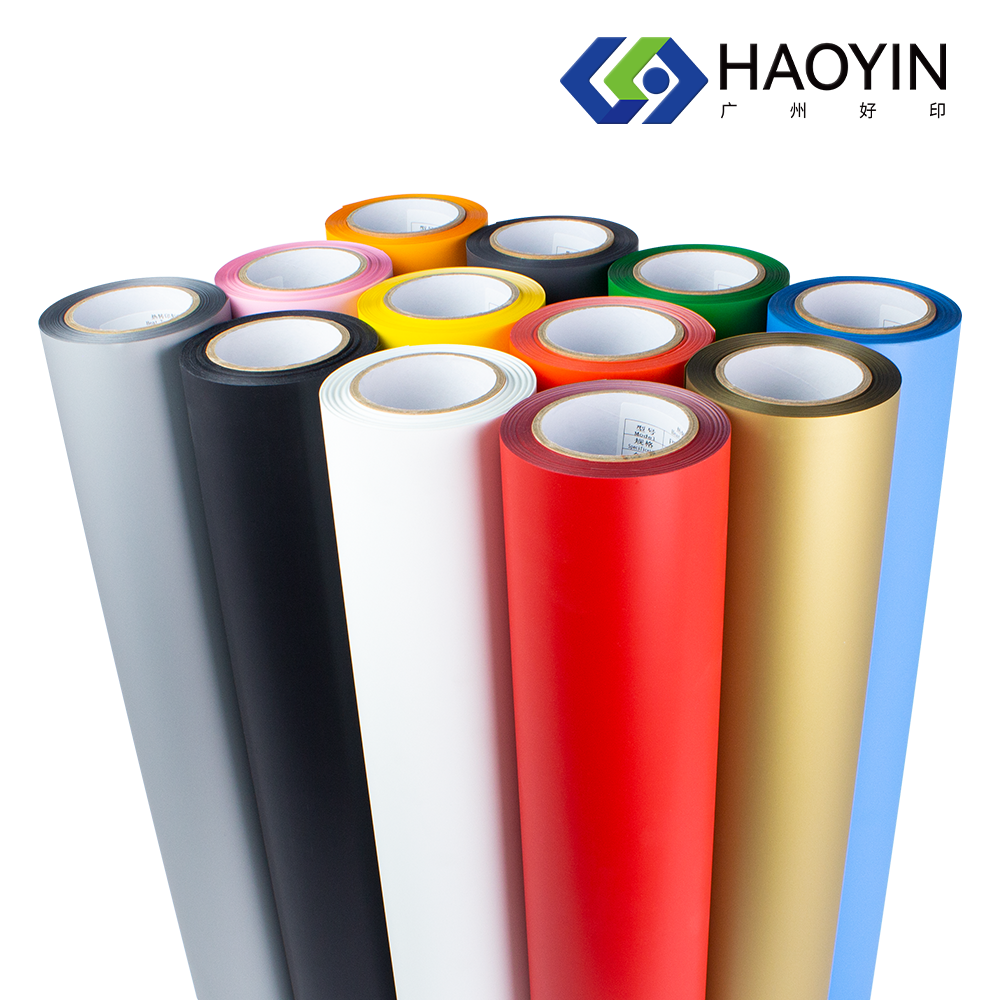

DTF (Direct to Film) powder and film represent a revolutionary advancement in textile printing technology. The system consists of specialized PET film and hot melt adhesive powder working in tandem to create high-quality transfers for various fabric applications. The PET film serves as a carrier medium that receives the printed design, while the DTF powder acts as an adhesive agent that bonds the design to the fabric when heat is applied. This innovative process allows for exceptional color vibrancy, durability, and wash resistance. The film is specifically engineered with a unique coating that ensures optimal ink reception and prevents spreading, resulting in crisp, detailed designs. The powder, composed of high-quality polyamide materials, melts at specific temperatures to create a strong, flexible bond between the printed design and the fabric. This versatile system can be used on a wide range of materials, including cotton, polyester, blends, leather, and even some non-textile surfaces. The technology eliminates the need for traditional transfer papers or pre-treatment processes, streamlining the production workflow and reducing material waste. Additionally, the DTF process allows for printing white underbase layers, enabling vibrant designs on dark fabrics without compromise in quality.