dtf printer with white ink

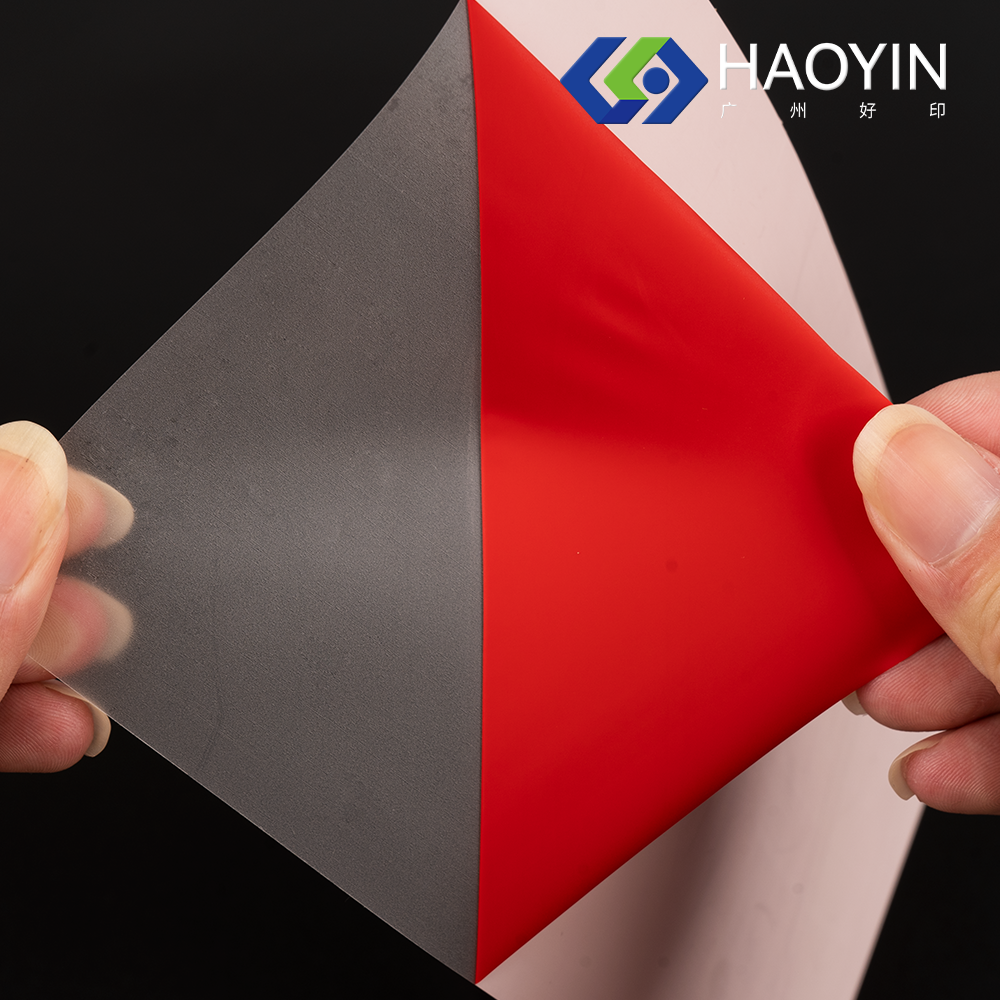

The DTF printer with white ink represents a breakthrough in direct-to-film printing technology, offering a versatile solution for custom garment decoration. This innovative printing system utilizes specialized PET films and a dual-layer printing process, where white ink serves as a crucial base layer for vibrant color reproduction. The printer's advanced technology enables it to deposit precise layers of ink, including white ink, onto transfer films, creating durable and washable designs that can be applied to various fabric types. What sets this printer apart is its ability to handle both light and dark garments effectively, thanks to the white ink layer that ensures color vibrancy regardless of the substrate color. The system incorporates sophisticated temperature control mechanisms and precision nozzle technology to maintain consistent ink flow and optimal print quality. The DTF printing process involves printing the design in reverse on the film, applying white ink as needed, and then coating with hot melt powder before heat pressing onto the garment. This technology is particularly valuable for businesses seeking to produce high-quality custom apparel, as it eliminates the need for pre-treatment and works effectively on various materials including cotton, polyester, silk, and blended fabrics.