DTF (Direct to Film) printing offers vivid colors, wide material compatibility, and flexible operation, making it popular in garment decoration and custom printing. However, printhead clogging is one of the most common issues that can lead to ink breaks, missing colors, blurry prints, or even production downtime.

Long periods without proper maintenance

Low-quality or incompatible inks

Unstable temperature and humidity

Improper cleaning methods

Minor Clogging – Run the printer’s auto-clean function 1–2 times → Test print → Resume work.

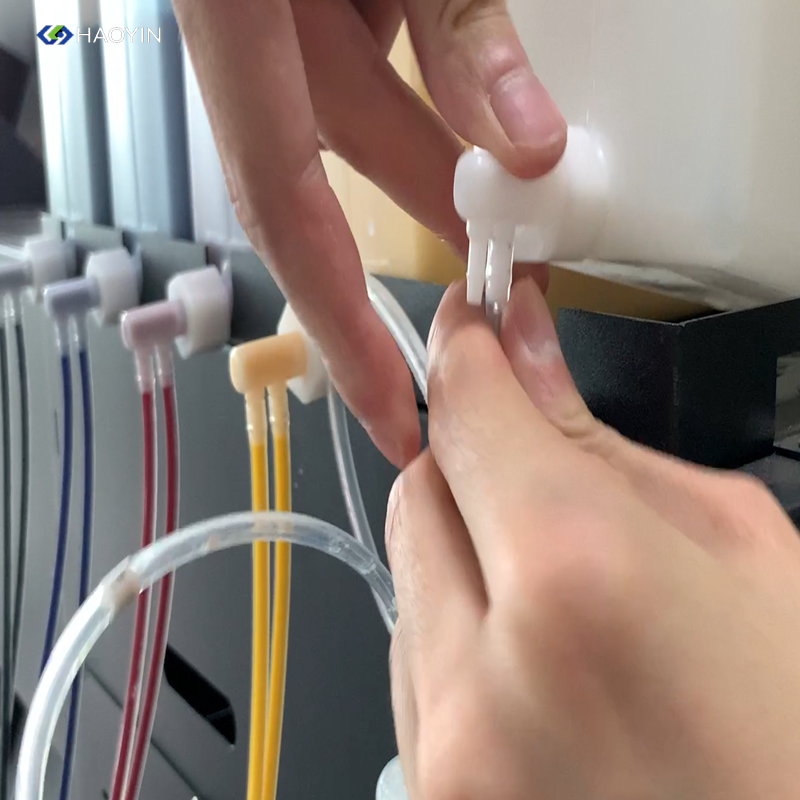

Moderate Clogging – Apply DTF printhead cleaning solution and let it soak for 30–60 minutes → Clean again.

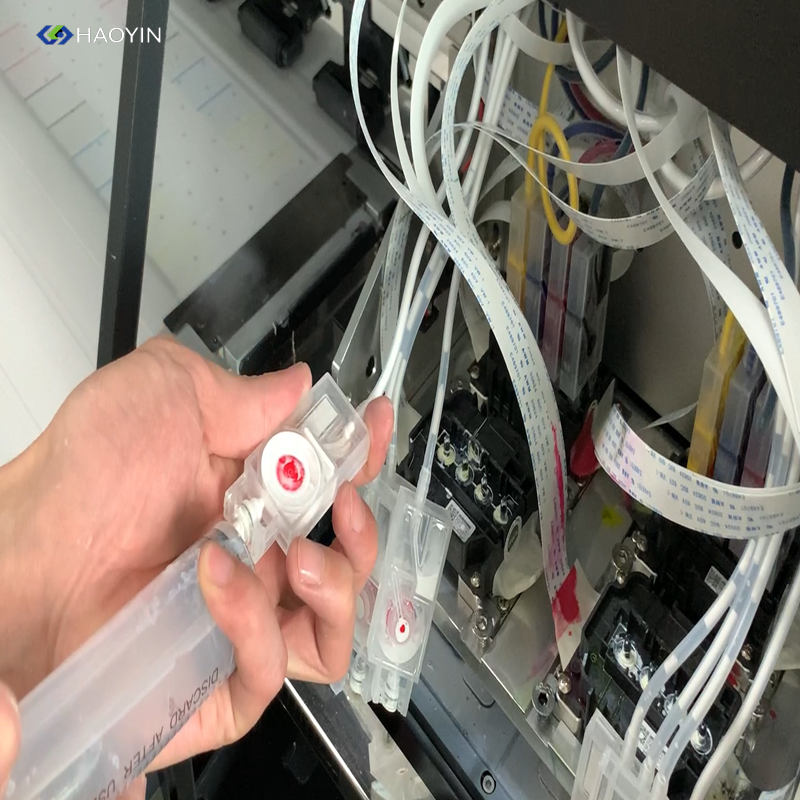

Severe Clogging – Have a technician perform ultrasonic cleaning or replace the printhead if necessary.

Print a nozzle test or small design every 2–3 days.

Use high-fluidity anti-clogging DTF inks and certified consumables.

Keep the environment at 20–28°C, 40–60% humidity.

Always park the printhead in its capping station before shutdown.

Printhead clogging is a preventable problem. With regular maintenance, proper cleaning, and high-quality consumables, you can significantly reduce downtime and extend your printer’s lifespan.

We offer:

Anti-clogging DTF inks (stable and smooth)

High-release PET films (easy peel, vibrant colors)

Eco-friendly hot-melt powders (low residue, smooth coating)

Contact us today to get free technical support and factory-direct pricing!

Hot News

Hot News2025-11-20

2025-11-13

2025-11-06

2025-10-30

2025-10-23

2025-10-16