In the field of custom apparel and garment printing, DTF heat transfer and CMYK heat transfer (offset heat transfer) are two mainstream technologies, but they differ significantly in terms of process, print quality, and application scenarios. Below is a detailed comparison:

✅ DTF Heat Transfer:

Uses digital direct printing + white ink underbase. The design is printed directly onto transfer film using an inkjet printer and then heat-pressed onto fabric.

Core advantage: Built-in white ink layer ensures vibrant colors on dark garments.

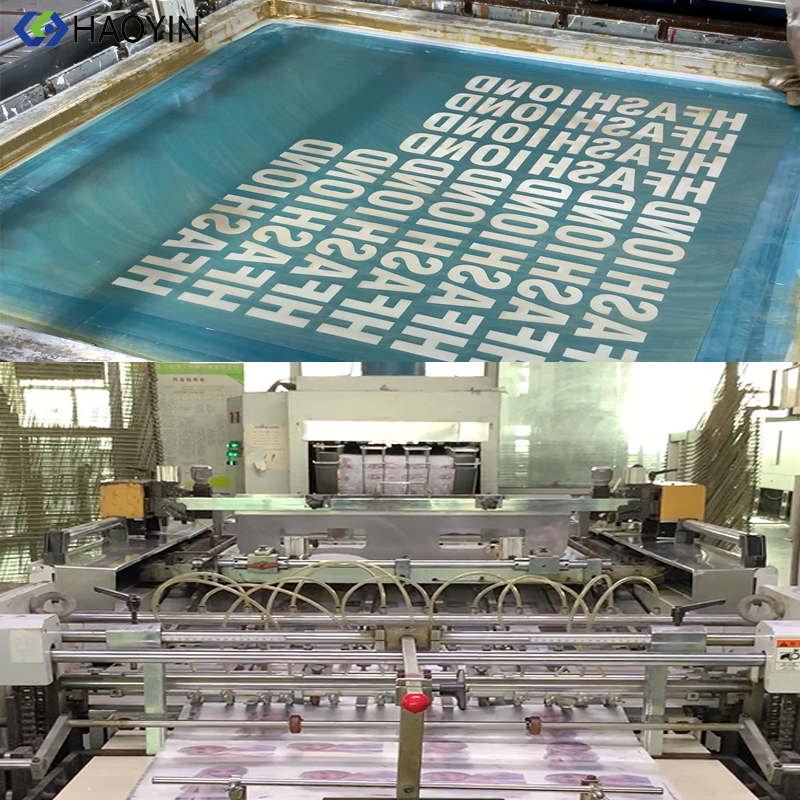

✅ CMYK Heat Transfer (Offset Heat Transfer):

Based on traditional four-color printing (CMYK) + adhesive coating, similar to offset printing in the commercial printing industry. Requires plate-making before transfer.

Relies on adhesive coating for bonding but lacks white ink—additional white base is needed for dark fabrics.

✅ DTF Heat Transfer:

Brighter colors—white underbase ensures accurate color reproduction on dark fabrics (e.g., black T-shirts).

Better for gradients and high-detail designs.

✅ Offset Heat Transfer:

Depends on CMYK color mixing; dark fabrics require an extra white adhesive layer, or colors will appear dull.

Best for simple designs; fine details may appear blurry.

✅ DTF Heat Transfer:

Softer feel—the print blends seamlessly with fabric, offering better breathability.

Highly wash-resistant; long-lasting without cracking.

✅ Offset Heat Transfer:

Thicker adhesive layer results in a stiffer feel, which may affect comfort for large prints.

Adhesive may develop minor cracks after repeated washing.

✅ DTF Heat Transfer:

Ideal for dark fabrics, high-detail designs, and small-batch customization (e.g., streetwear brands, products).

Flexible for on-demand printing—no plate-making needed, great for e-commerce and small studios.

✅ Offset Heat Transfer:

Best for light-colored fabrics and bulk orders (e.g., promotional shirts, team uniforms).

Low-cost for large quantities but requires plate-making—not ideal for complex designs.

✅ DTF Heat Transfer:

Higher per-unit cost, but no plate fees—cost-effective for small batches.

Fast production—print on demand.

✅ Offset Heat Transfer:

Cheaper for bulk orders, but plate-making increases costs for small runs.

Economical only for large-scale production.

| Factor | DTF Heat Transfer | Offset Heat Transfer |

|---|---|---|

| Fabric Suitability | Works on dark & light fabrics | Best on light fabrics (needs white base for dark) |

| Print Detail | High resolution, smooth gradients | Good for simple designs |

| Texture | Soft, breathable | Stiff (noticeable adhesive layer) |

| Production Flexibility | No plates, great for small batches | Requires plates, best for bulk |

| Cost Efficiency | Higher per unit, good for small orders | Cheaper in bulk, costly for small runs |

Recommendation:

Want premium quality & customization? Choose DTF Heat Transfer!

Need budget-friendly bulk orders? Go for Offset Heat Transfer!

Both technologies have their strengths—your choice depends on your needs! For streetwear brands, custom shops, or e-commerce, DTF heat transfer delivers superior color and texture. For promotional or corporate orders, Offset heat transfer offers a cost-effective solution.

Hot News

Hot News2025-08-28

2025-08-18

2025-08-11

2025-08-04

2025-07-25

2025-07-23