When using heat transfer vinyl (HTV), placing the correct side down is crucial for a successful transfer. Here’s how to identify it:

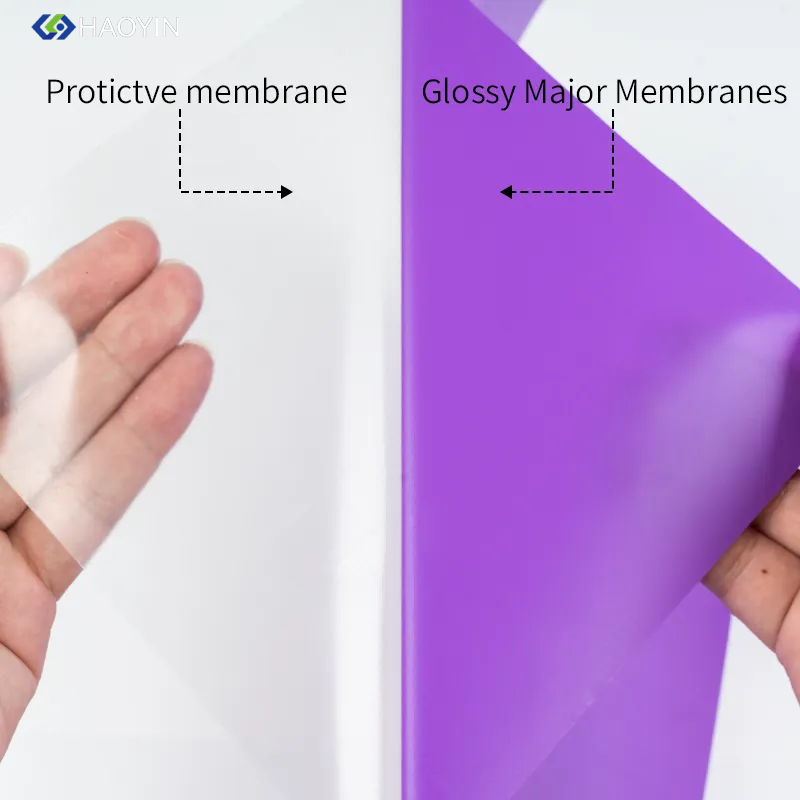

Carrier Sheet (Shiny Side) → UP

The clear, plastic-like layer (carrier sheet) faces UP during cutting and weeding.

This side protects the adhesive vinyl and is removed after pressing.

Adhesive Vinyl (Matte/Colored Side) → DOWN

The colored or textured side (actual vinyl) faces DOWN onto the fabric.

This is the side that bonds to the material when heated.

Touch Test: The adhesive side is slightly tacky (sticks lightly to fingers).

Visual Clue: The carrier sheet is smooth/glossy; the vinyl side is matte or colored.

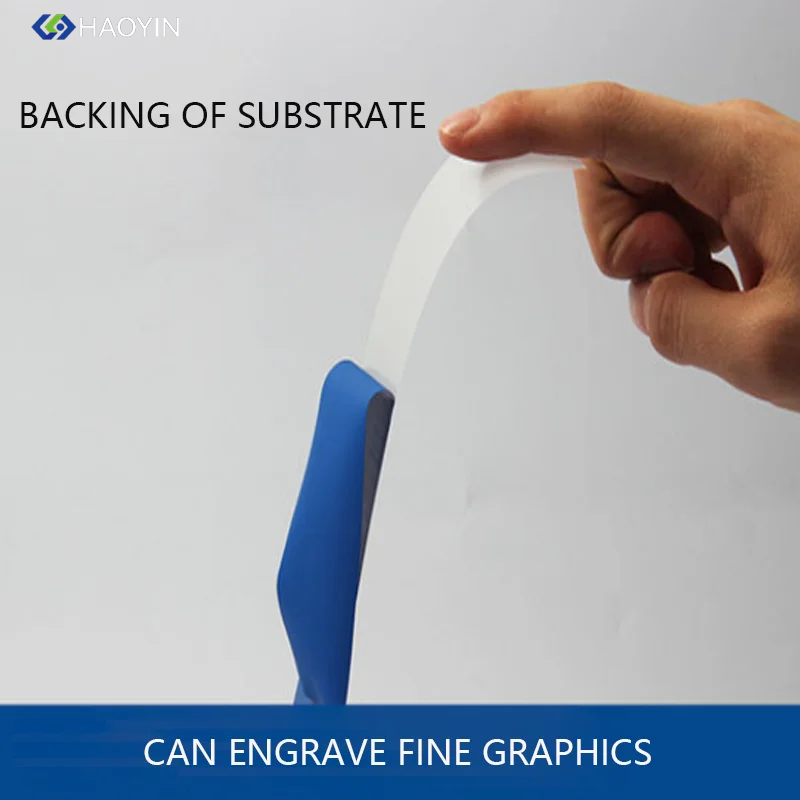

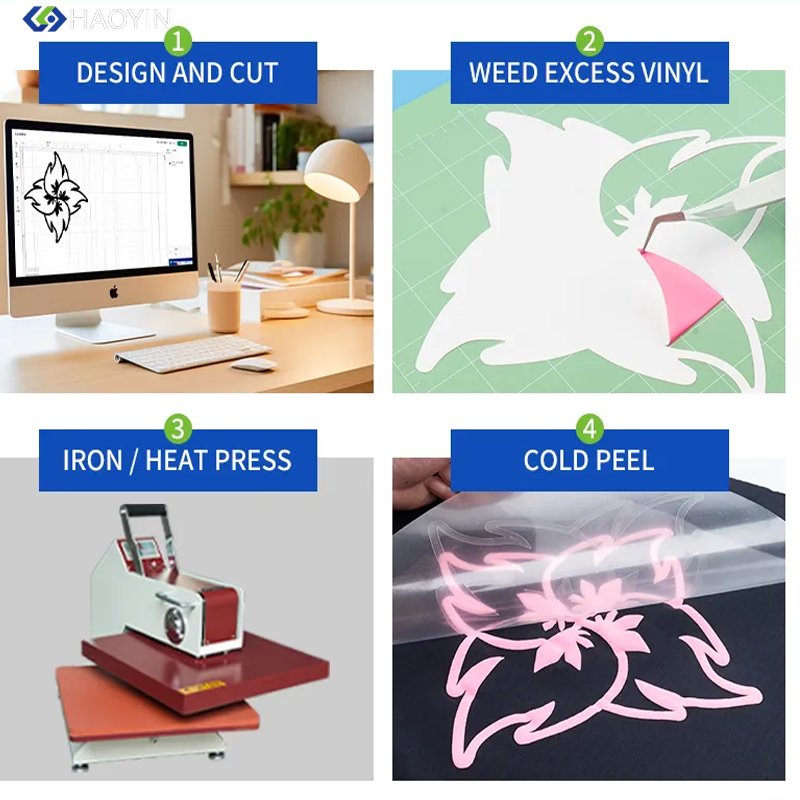

Cut: Load HTV into your cutter with the carrier sheet (shiny side) down on the mat.

Weed: Remove excess vinyl from the carrier sheet, leaving your design.

Press: Place the design adhesive-side down on the fabric, with the carrier sheet still on top.

Peel: After heating, remove the carrier sheet (hot or cold peel, depending on HTV type).

❌ Placing the shiny carrier sheet down on the fabric (vinyl won’t stick).

❌ Forgetting to mirror your design before cutting (for text/images).

Pro Tip: If using an iron, cover the design with parchment paper to protect the carrier sheet while pressing.

Hot News

Hot News2025-08-28

2025-08-18

2025-08-11

2025-08-04

2025-07-25

2025-07-23