dtf printing

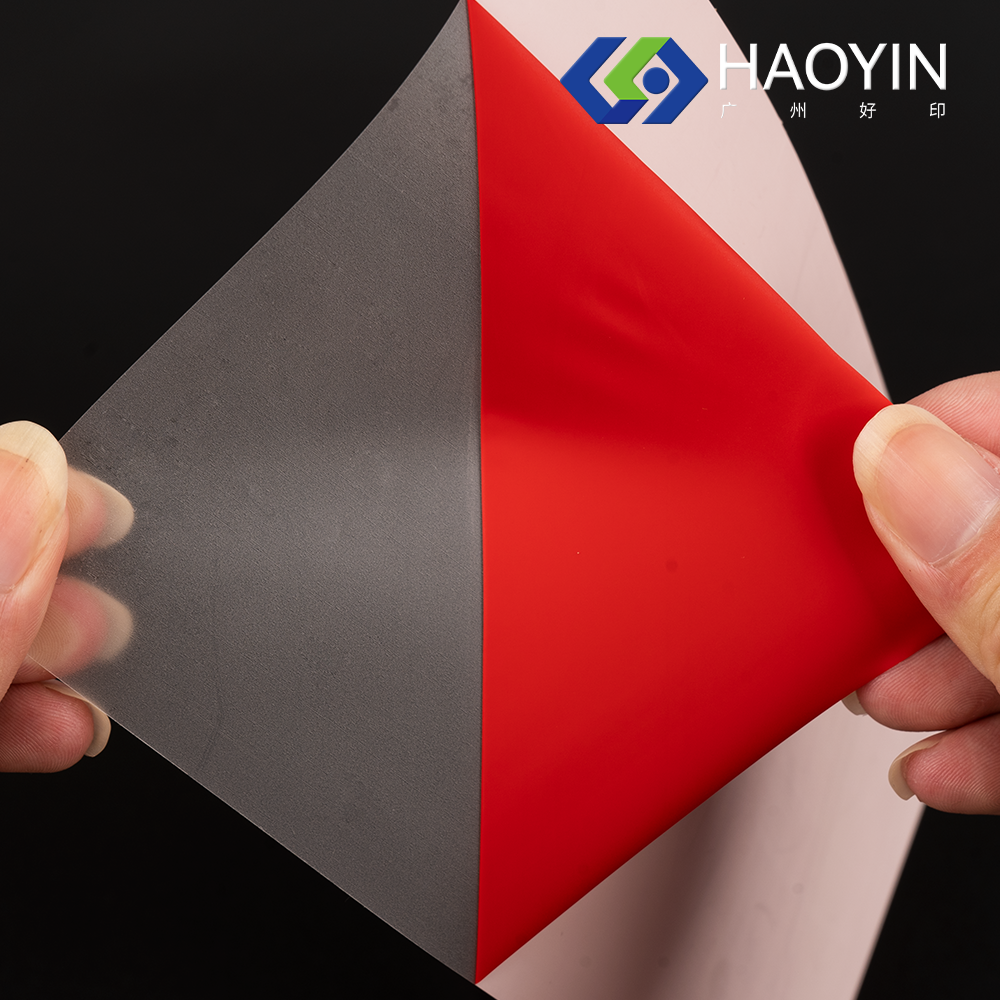

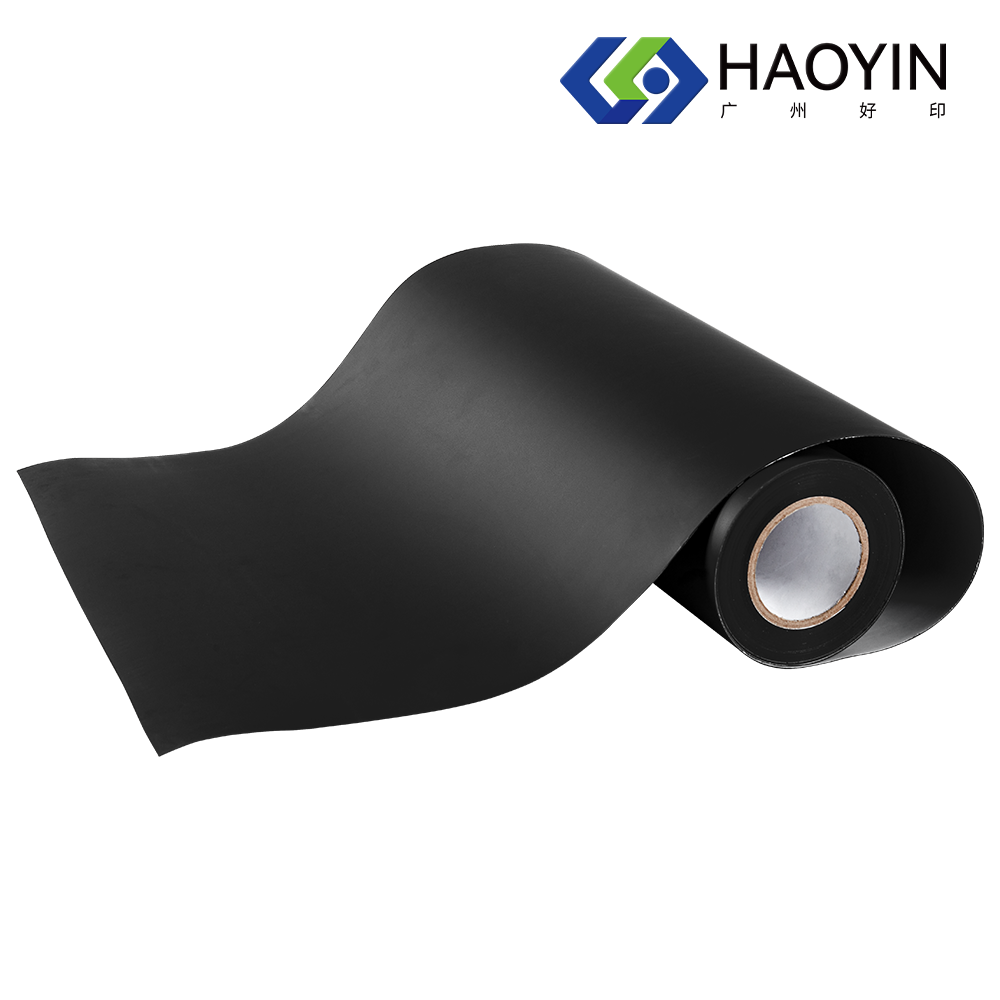

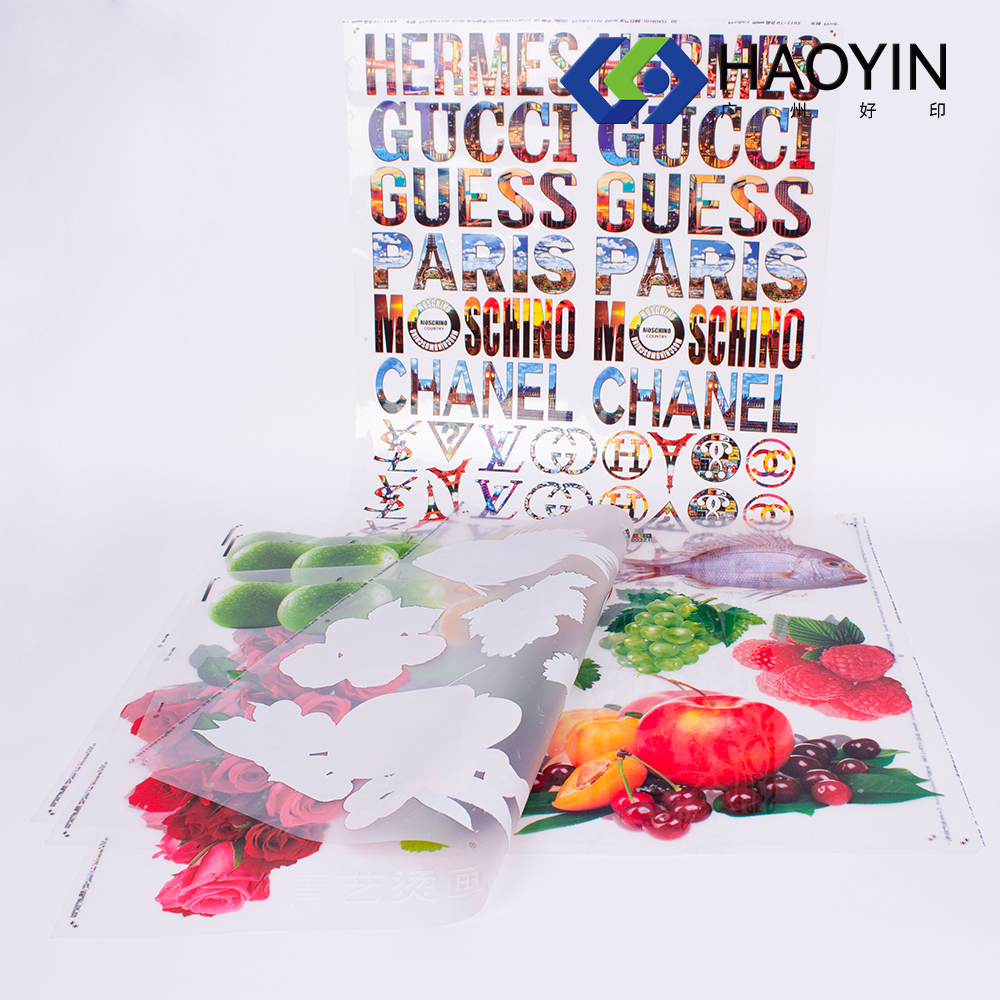

DTF (Direct to Film) printing represents a revolutionary advancement in the garment decoration industry, offering a versatile and efficient method for creating high-quality transfers that can be applied to various fabrics and materials. This innovative printing technology involves directly printing designs onto a specialized PET film using water-based inks, followed by the application of a hot-melt adhesive powder. The process begins with the digital creation of the design, which is then printed onto the film using specialized DTF printers equipped with white and CMYK ink channels. The printed film passes through a curing process where the hot-melt adhesive powder is applied and melted, creating a transfer that can be heat-pressed onto virtually any fabric. DTF printing has gained significant popularity due to its ability to produce vibrant, durable prints with excellent wash-fastness and stretch properties. The technology excels in reproducing complex designs with fine details and gradients, making it particularly suitable for photorealistic images and intricate artwork. Unlike traditional printing methods, DTF doesn't require pre-treatment of garments and can be applied to both light and dark fabrics with equal effectiveness. This technology has found widespread applications in custom t-shirt printing, sportswear production, promotional merchandise, and small-batch clothing manufacturing.