The main difference between puff vinyl and regular vinyl (also called standard heat transfer vinyl or HTV) lies in texture, appearance, and finish after heat application:

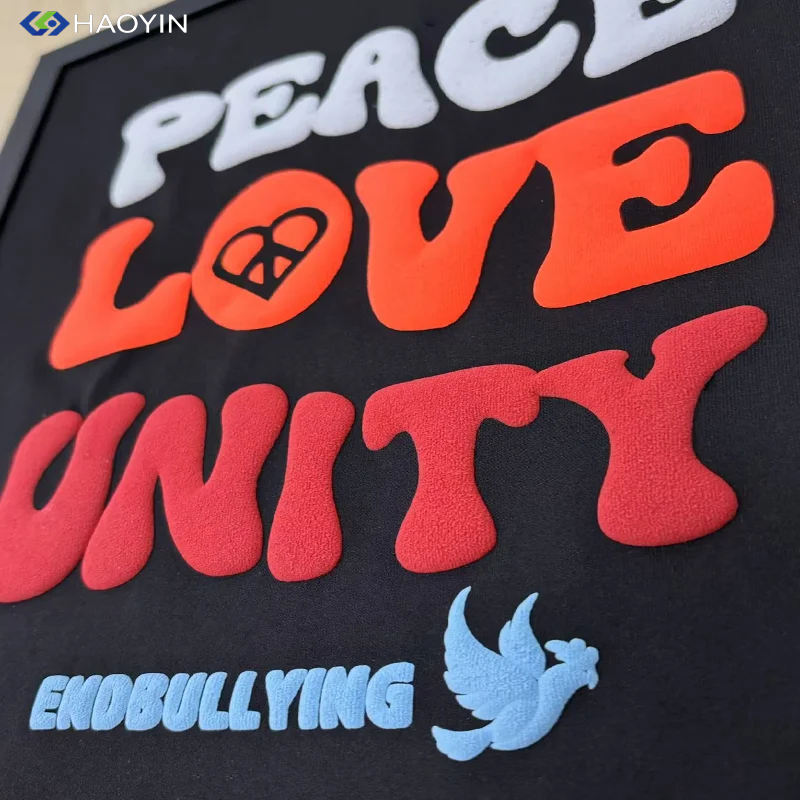

Texture/Effect: Expands ("puffs") and creates a raised, 3D effect when heat-pressed.

Finish: Often soft, matte, and sponge-like.

Thickness: Starts thin, but expands significantly during pressing.

Design Look: Ideal for bold text or simple graphics. Not good for fine details (they can blur when puffed).

Heat Press Tips: Requires precise time, temperature, and pressure for correct puffing—typically higher heat (around 320–340°F / 160–170°C).

✅ Great for: Streetwear, bold logos, tactile textures.

Texture/Effect: Flat and smooth; sticks closely to the garment.

Finish: Can be glossy, matte, glitter, or metallic, depending on the type.

Thickness: Consistent, usually thin and flexible.

Design Look: Suitable for detailed cuts, fine text, and intricate shapes.

Heat Press Tips: Easier to press, more forgiving with temperature and pressure.

✅ Great for: Everyday T-shirts, performance wear, detailed designs.

| Feature | Puff Vinyl | Regular Vinyl (HTV) |

|---|---|---|

| Look | 3D, raised | Flat, smooth |

| Texture | Soft, foamy | Varies (smooth, matte, etc.) |

| Detail Support | Not ideal for fine detail | Excellent for fine detail |

| Pressing | Needs precision | Easier, more forgiving |

| Best For | Bold, fun effects | Versatile everyday use |

Hot News

Hot News2025-08-28

2025-08-18

2025-08-11

2025-08-04

2025-07-25

2025-07-23