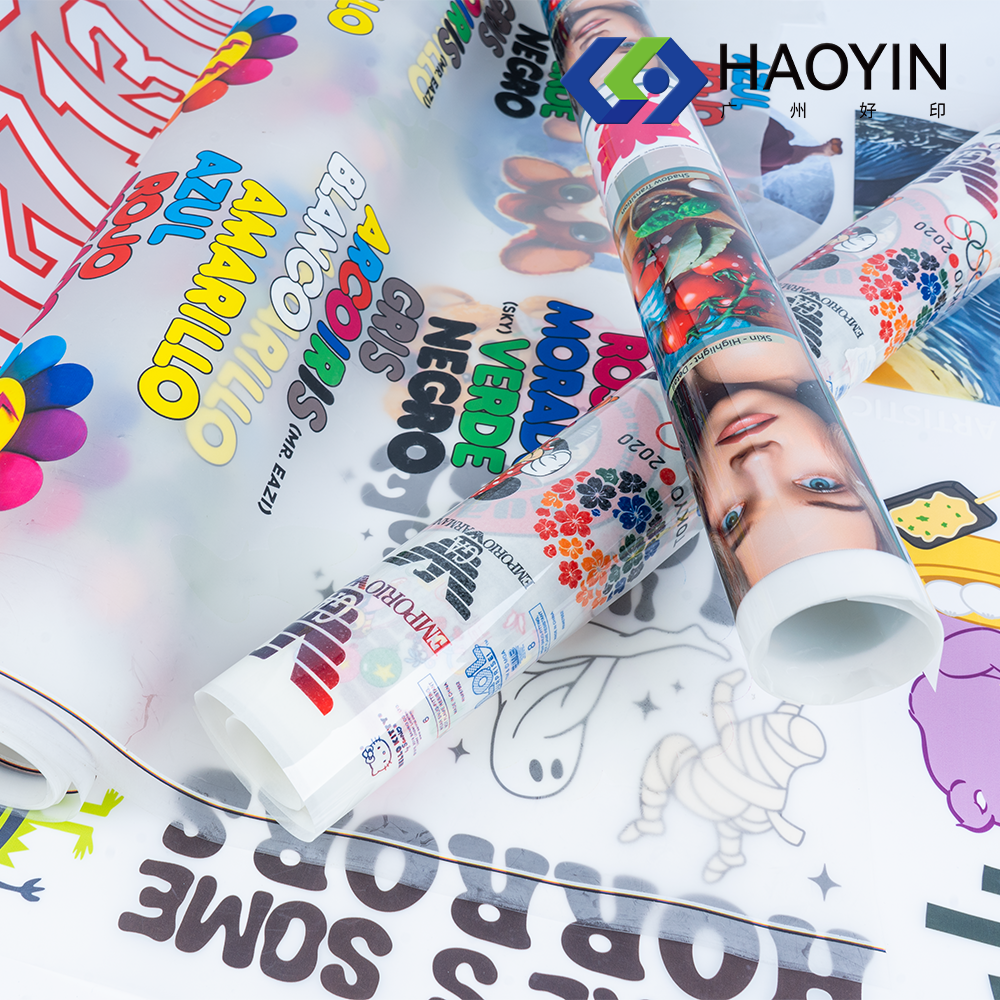

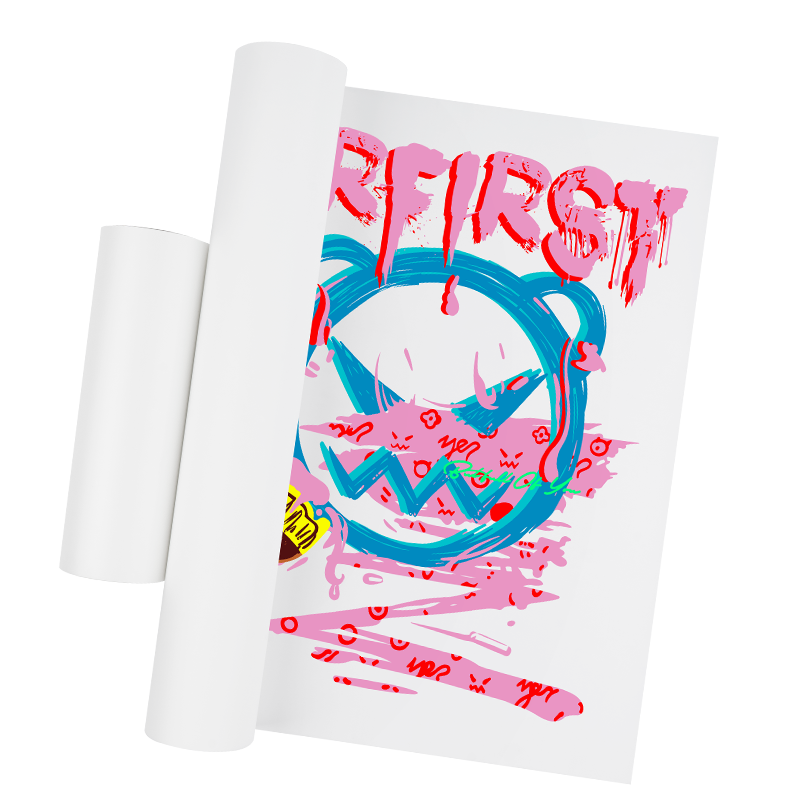

Direct-to-Film printing has revolutionized the textile customization industry by offering unprecedented flexibility and quality in garment decoration. Understanding how to properly print DTF film ensures optimal transfer results, vibrant colors, and long-lasting designs that maintain their integrity through multiple wash cycles. This comprehensive guide explores the essential techniques, equipment considerations, and best practices that professional printers employ to achieve consistently superior outcomes when working with this innovative printing technology.

The quality of your final printed product depends heavily on understanding the fundamental principles of DTF technology and implementing proper printing procedures. Professional results require attention to detail throughout every stage of the process, from initial file preparation through final heat application. Modern DTF systems offer remarkable versatility for decorating various fabric types while maintaining cost-effectiveness for both small-scale customization and large production runs.

Essential Equipment Setup for DTF Printing

Printer Configuration and Maintenance

Proper printer setup forms the foundation of successful DTF operations, requiring specific modifications to standard inkjet printers for optimal performance. The printer head height must be precisely calibrated to accommodate the thickness of DTF media while preventing head strikes that could damage both equipment and materials. Regular maintenance schedules including head cleaning, alignment verification, and ink system flushing prevent common issues that compromise print quality and consistency.

Temperature and humidity control within the printing environment significantly impacts adhesion properties and drying characteristics of DTF inks. Maintaining stable conditions between 68-75°F with relative humidity levels of 45-55% creates optimal conditions for ink deposition and prevents premature drying or inadequate curing. Professional installations often incorporate environmental monitoring systems to ensure consistent atmospheric conditions throughout production cycles.

Ink System Optimization

DTF ink formulations require specific handling procedures to maintain viscosity and prevent settling of pigment particles during storage and use. Regular agitation of ink supplies and proper storage temperatures preserve ink quality while preventing costly waste from degraded materials. The ink delivery system must be purged and cleaned according to manufacturer specifications to prevent cross-contamination between color channels.

White ink management presents unique challenges due to its higher pigment density and tendency to settle more rapidly than process colors. Implementing automated circulation systems or establishing manual agitation protocols ensures consistent white ink density throughout production runs. Proper white ink opacity is crucial for achieving vibrant colors on dark garments and maintaining design integrity across different fabric colors.

Advanced Printing Techniques and Settings

Resolution and Pass Configuration

Print resolution selection directly impacts both quality and production speed, requiring careful balance based on design complexity and intended application. Higher resolution settings of 1440x1440 dpi deliver exceptional detail reproduction for intricate designs while standard 720x720 dpi provides adequate quality for most commercial applications at faster production speeds. Multi-pass printing configurations enhance color saturation and coverage uniformity but extend processing times significantly.

Bidirectional printing can introduce alignment issues that manifest as banding or color registration problems in final transfers. Implementing unidirectional printing modes eliminates these alignment concerns while maintaining consistent print quality across the entire image area. The trade-off between print speed and quality must be evaluated based on specific production requirements and quality standards.

Color Management and Profiling

Accurate color reproduction requires comprehensive color management systems that account for ink characteristics, film properties, and final substrate interactions. Custom ICC profiles developed specifically for your DTF system ensure predictable color output and minimize waste from color correction iterations. Regular profile validation using standardized color targets maintains accuracy as equipment ages and consumables change.

The interaction between DTF inks and various fabric types can significantly alter final color appearance, necessitating substrate-specific color adjustments. Developing color correction matrices for common fabric types streamlines production workflows and ensures consistent results across different garment materials. Professional color management tools enable precise control over individual color channels and overall color balance.

Film Handling and Processing Best Practices

Powder Application Techniques

Hot melt powder application requires precise timing and technique to achieve optimal adhesion without compromising print quality or creating texture issues in final transfers. The DTF film must receive powder application while inks remain sufficiently tacky to ensure proper adhesion but not so wet that powder creates clumping or uneven distribution. Automated powder application systems provide consistent coverage while reducing labor requirements and material waste.

Excess powder removal must be performed thoroughly to prevent contamination of curing equipment and ensure clean transfer edges. Proper powder reclamation systems recover unused material for reuse while maintaining powder quality standards. The powder curing process requires precise temperature control to activate adhesive properties without degrading ink chemistry or film substrate.

Curing and Drying Procedures

Controlled curing processes ensure complete ink polymerization and powder activation while preventing over-curing that can compromise transfer flexibility. Conveyor dryer systems provide consistent heat exposure across the entire film surface, eliminating hot spots that could cause uneven curing or film distortion. Temperature monitoring throughout the curing chamber enables real-time adjustments to maintain optimal processing conditions.

Post-curing cooling procedures prevent film distortion and ensure dimensional stability of finished transfers. Controlled cooling rates allow internal stresses to dissipate gradually while maintaining transfer flatness essential for proper application. Storage conditions for cured transfers must protect against moisture absorption and mechanical damage until final application.

Transfer Application and Heat Press Techniques

Temperature and Pressure Optimization

Heat press settings require precise calibration based on fabric type, transfer size, and desired hand feel characteristics of the finished product. Temperature ranges typically span 300-350°F with pressure settings adjusted to ensure complete adhesive activation without fabric scorching or transfer distortion. Digital temperature monitoring eliminates guesswork and ensures consistent application parameters across production batches.

Pressure distribution across the heat press platen significantly affects transfer adhesion uniformity, particularly with larger designs or irregular garment surfaces. Proper platen maintenance including surface cleaning and alignment verification prevents transfer failures and ensures professional finished appearance. Pressure adjustment capabilities enable optimization for different fabric weights and construction types.

Timing and Peel Techniques

Press timing must account for heat penetration through fabric layers while allowing sufficient dwell time for complete adhesive activation. Thicker fabrics and multi-layer constructions require extended press times to ensure heat reaches the film-fabric interface effectively. Timer accuracy becomes critical for maintaining consistency across large production runs and preventing under-cured or over-processed transfers.

Peel timing and technique directly impact final transfer appearance and durability, with cold peel applications generally providing superior results compared to hot peel methods. Proper peel angles and controlled removal speeds prevent film tearing or incomplete release from carrier materials. Quality control procedures should verify complete film release and adhesion integrity before final inspection and packaging.

Troubleshooting Common Issues

Print Quality Problems

Banding artifacts typically result from inconsistent ink flow, printer head alignment issues, or improper media feed mechanisms. Systematic troubleshooting procedures isolate the root cause through test print evaluation and equipment inspection protocols. Regular maintenance schedules prevent most print quality issues while minimizing production disruptions and material waste.

Color accuracy problems often stem from incorrect color management settings, degraded ink quality, or environmental condition variations. Implementing standardized color control procedures including regular profile verification and test print evaluation maintains consistent color output. Documentation of color correction procedures enables rapid problem resolution and prevents recurring issues.

Transfer Application Failures

Poor adhesion typically results from inadequate heat press settings, contaminated fabric surfaces, or compromised film storage conditions. Systematic evaluation of press parameters, fabric preparation procedures, and storage protocols identifies corrective actions. Fabric pretreatment procedures may be necessary for certain synthetic materials or heavily finished textiles.

Film peeling or delamination issues often indicate incorrect peel timing, inadequate curing, or incompatible fabric-adhesive combinations. Establishing standardized application procedures and quality control checkpoints prevents most transfer failures while ensuring consistent finished product quality. Customer education regarding garment care procedures extends transfer longevity and reduces warranty claims.

FAQ

What temperature should I use for DTF film transfers

The optimal temperature for DTF film transfers typically ranges from 300-350°F depending on the specific film manufacturer recommendations and fabric type. Cotton and cotton blends generally require temperatures around 320-330°F, while polyester and synthetic materials may need slightly higher temperatures up to 350°F. Always consult your film supplier's guidelines and perform test transfers to determine the ideal temperature for your specific combination of materials.

How long should I press DTF transfers

Standard DTF transfer press times range from 15-20 seconds for most applications, though this can vary based on fabric thickness, transfer size, and heat press specifications. Thicker garments or larger designs may require extended press times up to 25-30 seconds to ensure proper heat penetration and adhesive activation. Monitor the transfer during pressing and adjust timing based on your specific equipment and material combinations.

Why is my DTF film not adhering properly to fabric

Poor DTF film adhesion typically results from insufficient heat press temperature, inadequate pressure, contaminated fabric surfaces, or expired transfer materials. Ensure your heat press reaches the correct temperature and applies even pressure across the entire design area. Pre-press garments to remove moisture and sizing chemicals that can interfere with adhesion. Store DTF transfers in dry, cool conditions to maintain adhesive properties.

Can DTF film be used on all fabric types

DTF film works effectively on most fabric types including cotton, polyester, cotton-polyester blends, and many synthetic materials. However, fabrics with special coatings, water-resistant treatments, or extremely high stretch content may require modified application parameters or may not be suitable for DTF transfers. Always test transfer compatibility on a sample piece before proceeding with full production to ensure proper adhesion and durability.